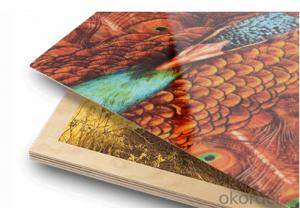

HD Aluminium Metal Art Pictures Print on HD Aluminium Metal Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

- Q:you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q:Hey I just noticed that my deodorant/antiperspirant has aluminum in it. I remember reading that this is bad for you. My question is, will this be dangerous for my health in the long run?

- Deodorants do not contain aluminum, only antiperspirants do. The aluminum is used to stop sweating from occurring. There are natural antiperspirants (example Tom's of Main) that claim to stop sweat without the use of aluminum. Aluminum based products have been associated with quite a few health problems: Seizures Breast Cancer Alzheimer's Disease Bone Formation Disorders Kidney Problems Hope this helps.

- Q:What is the shear strength of 101 aluminum sheets?

- The shear strength of 101 aluminum sheets may differ based on different factors like sheet thickness, aluminum alloy composition, and manufacturing process employed. Typically, the shear strength of 101 aluminum sheets falls between 20,000 and 30,000 pounds per square inch (psi). Nevertheless, it should be emphasized that these values are approximate, and precise figures can vary. For precise information on the shear strength of 101 aluminum sheets, it is advisable to refer to the material's technical data sheet or contact the manufacturer directly.

- Q:Are 101 aluminum sheets suitable for solar panel frames?

- Indeed, solar panel frames can be made using 101 aluminum sheets, which are highly suitable for this purpose. The grade 101 aluminum is widely utilized and recognized for its outstanding strength and ability to resist corrosion. These characteristics render it an optimal material for constructing frames that can endure the elements and offer ample support for solar panels. Furthermore, 101 aluminum sheets are lightweight, facilitating the straightforward installation and transportation of solar panels. In summary, the strength, corrosion resistance, and lightweight properties of 101 aluminum sheets make them a fitting option for solar panel frames.

- Q:How do you ensure the surface quality of aluminum sheets?

- To guarantee the surface quality of aluminum sheets, manufacturers can take several steps: 1. Cleanliness is crucial. Prior to any surface treatment or inspection, it is vital to thoroughly clean the aluminum sheets and eliminate any dirt, grease, or contaminants. This can be accomplished using solvents, detergents, or specialized cleaning agents. 2. A visual inspection is necessary. Trained personnel should visually inspect the surface for visible flaws such as scratches, dents, or pitting. Proper lighting and magnification tools should be utilized. 3. Chemical treatments may be required. Depending on the desired surface finish and application, aluminum sheets may undergo chemical treatments such as anodizing, chromate conversion coating, or passivation. These processes can enhance the sheets' surface quality, corrosion resistance, and aesthetic appearance. 4. Mechanical polishing can be employed. To eliminate surface imperfections and achieve a smooth, glossy finish, mechanical polishing techniques like grinding, buffing, or sanding can be utilized. It is important to maintain consistency and avoid over-polishing, which can compromise the integrity of the sheets. 5. Coating and protection are essential. Applying protective coatings like lacquers, paints, or powder coatings can further improve the surface quality, appearance, and durability of aluminum sheets. These coatings act as a barrier against corrosion, abrasion, and environmental factors. 6. Quality control is crucial. Rigorous quality control procedures should be implemented throughout the manufacturing process. Regular inspections, testing, and documentation should be conducted to ensure that the surface quality of aluminum sheets meets the required standards and specifications. 7. Proper handling and packaging are necessary. To prevent surface damage during transportation and storage, it is important to handle and package the sheets correctly. Protective measures such as using protective films, paper interleaves, or cushioning materials should be employed to safeguard the surface quality until the sheets reach their final destination. By following these measures, manufacturers can ensure that the surface quality of aluminum sheets meets the desired specifications and exceeds customer expectations.

- Q:How do aluminum sheets compare to steel sheets in terms of weight?

- In terms of weight, aluminum sheets are much lighter than steel sheets. The reason for this is that aluminum has a lower density, making it a more versatile and lightweight material compared to steel. The extent of the weight difference between aluminum and steel sheets will vary depending on the thickness and dimensions of the sheets. However, as a general rule, aluminum sheets can weigh approximately 1/3 less than steel sheets of the same dimensions. This quality makes aluminum sheets particularly suitable for industries like aerospace, where weight is a crucial consideration, as well as for lightweight structures.

- Q:Can 101 aluminum sheets be painted or coated?

- Certainly! Aluminum sheets offer the possibility of being painted or coated. This adaptable material lends itself to receiving a range of finishes, including paint or protective coating, which can both elevate its visual appeal and safeguard it against corrosion. Whether it pertains to 101 aluminum sheets or any other aluminum variant, diverse techniques like spray painting, powder coating, or anodizing can be employed to paint or coat them. The selection of the appropriate paint or coating shall be contingent upon the desired aesthetics, performance criteria, and the precise utilization of the aluminum sheets.

- Q:What are the different types of alloys used for anodized aluminum sheets?

- There are several different types of alloys that can be used for anodized aluminum sheets, each with its own unique properties and applications. Some of the commonly used alloys include: 1. 1000 series alloys: These alloys are primarily made of pure aluminum and are known for their excellent corrosion resistance. They are commonly used for anodized aluminum sheets in various industries, including architecture, automotive, and aerospace. 2. 5000 series alloys: These alloys contain magnesium as the primary alloying element, which provides enhanced strength and excellent weldability. They are often used for anodized aluminum sheets in applications that require high strength and resistance to atmospheric corrosion. 3. 6000 series alloys: This series of alloys is known for its excellent combination of strength, extrudability, and corrosion resistance. The most commonly used alloy in this series for anodized aluminum sheets is 6061, which is widely used in structural components, marine applications, and consumer electronics. 4. 7000 series alloys: These alloys are known for their exceptional strength and are typically used in applications that require high-performance materials. The most common alloy in this series for anodized aluminum sheets is 7075, which is widely used in aerospace and defense industries. 5. 2000 series alloys: These alloys are primarily used in applications that require high strength and excellent fatigue resistance. They are commonly used in the aerospace industry for anodized aluminum sheets. It's important to note that the choice of alloy for anodized aluminum sheets depends on the specific requirements of the application, including desired strength, corrosion resistance, and other mechanical properties.

- Q:Hello,Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum?Thanks!

- Most cut-off wheels are grinding wheels. They get clogged up quickly with aluminum dust. A saw is a better idea.

- Q:I need to make an aluminum cylinder out of 1/8 6061 plate and tube. I don't have a TIG setup and was considering using Bernzomatic aluminum soldering rods. The cylinder will be pressurized from 20-60 psi. Assuming a clean job, is this pressure ok? How much pressure can the joint take? Also, although the solder does not need flux, should i use it anyway?

- to your setup i might merely persist with the iron. It would not sound like the burden mark downs is going to be properly actually worth the greater suitable probability for a on a regular basis motive force. forged iron is merely greater rugged and can take greater abuse than aluminum. Aluminum has its place yet its no longer in a on a regular basis motive force like it variety of feels you're development.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HD Aluminium Metal Art Pictures Print on HD Aluminium Metal Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords