HCSA Cement 92.5MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 10000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HCSA BINDER is manufactured under a strict quality assurance systems GB/T 19001-2000 and GB/T 24001-1996 which accommodates the

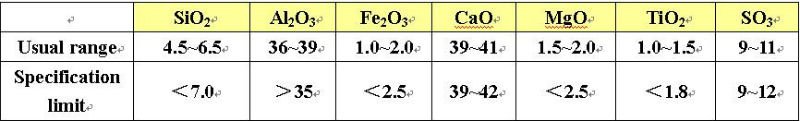

Chemical Analysis

The chemical analysis of HCSA BINDER has been determined according to the following:

GB/T 176-1996 Methods of chemical analysis for cement

Main constituents (%)

Fineness

Specific Surface Area: according to standard GB/T 8074-1987

Usual range: 360~430 m2/kg

Specification limit: >360 m2/kg

Reactivity with Portland cement

HCSA BINDER may be used in combination with other mineral products, for example PORTLAND cement, calcium sulphates and fillers, or with organics such as polymers in latex form or in redispersible form.

Depending on the type of mixes and technology employed, HCSA BINDER can be used to obtain and control various properties.

The behaviour of PORTLAND cement is vary variable. In general, acceleration of set increases progressly with the addition of HCSA BINDER. The amount of HCSA BINDER needed to obtain a specific setting time varies considerably depending on the origin of the PORTLAND cement and performance can be modified with the use of additives.

The strength development of HCSA BINDER/PORTLAND cement and/or Calcium Sulphates depend on the nature of the PORTLAND cement and/or Calcium Sulphates used. In general these mixes will develop mechanical strength at a very early stage (several hours). With some type of PORTLAND cements and in formulated products containing additives which control the setting and hydration, the long term properties is similar to those of the original PORTLAND cement, however it is necessary to check the behaviour of each PORTLAND cement used.

The characteristics of PORTLAND cement to be considered are:

1. C3A content

2. Mineral admixture type and content

3. Type of Calcium Sulphate used

Additives will also influence the properties of these mixes:

1. Setting time

2. Rheology

3. Mechanical performance

These properties are applied to obtain a wide range of products:

1. Fast setting cements

2. Rapid hardening mortars

3. Tile adhesives

4. Self-leveling compounds

5. Non-shrink grouts

6. Water stopping mortars

7. etc.

With a careful selection of the constituents (OPC, calcium sulphates, additives), it is possible to create mixes with a range of different hydraulic properties:

1. Adjustable setting time

2. Rheology adapted to the application

3. High early strength

4. High long term strength

5. Shrinkage compensation

Use of Additives

HCSA BINDER may be used in combination with chemical additives such as:

1. polymers, either in latex form or redispersible powder form

2. defoamers

3. retarders

4. accelerators

5. plasticizers/superplasticizers

6. rheology modifiers

7. fibers

- Q:I'm considering using hydraulic cement to stop my basement from leaking, We would like to finish it someday but want to make sure it won't leak later and cause more problems. Is it better to apply to the inside wall of the foundation or to dig around the house and apply to the outside? We don't have any obvious huge cracks that we've seen yet. Has anyone used hydraulic cement and have any tips/advice? Any help would be appreciated! Thanks!

- Use whatever you want, do whatever you want to with it. You have to fix the UNDERLYING problem first. Why is your basement leaking? Answer that question and we can help you more. Poor drainage scheme? Busted gutters and downspouts? Spring? Broken DWV line? Busted water supply line? Well? Find out the damn problem before trying to fix the symptom. You will be lots happier.

- Q:What three substances are mixed with cement to make concrete?

- Sand, gravel and water.

- Q:Hello All, I have had fixed dark brown tiles on my bathroom floor, however the guys did a bad job at it, and i can see the white cement in beween the tiles.. and its actually making the whole pattern look bad.. I was wondering if there was any way I could kind of colour the cement filling in between the tiles so that it blends with the colour of the tiles... ?Also any suggestions for removal of cement stains off these tiles? PLEASE Help, i am really in a mess here.

- There is a product which colors and seals at the same time. Sold in pint bottles. I used a q-tip to carefully paint it on only between the tiles. (remember this will seal it too...so take your time and put care into the application). Go to either Home Depot or Lowes. Look in tile department. It says it is to color grout. But, grout and the white cement (really called either thin set or mastic) is the basically same stuff and will color the same way.

- Q:and what is their #Basically, in out rental house, it looks like the guy dumped a bucket of motor oil on the garage floor and then used the oil to paint a section of the floor. And his car dripped everywhere on the other half of the garage. So now the while garage has drips of oil everywhere and looks kind of like the black parts of this freeway. And to make matters worse, it is totally soaked in to the cement.

- I used degreaser on mine I found it at the automotive store. and than I hosed it down with a power washer.

- Q:I live in a bright purple cement rendered home and want to paint it dark grey, but am unsure what paint to use or if I have to do any preparation to it before painting itPlease helpBrands available in Australia will helpThanks

- First, try using a power washer in the 2000 PSI range to take off the old paint. If it comes off (or most of it, anyway), let the cement dry for a couple days and then use a concrete primer before applying a color coat specifically made for concrete. The primer is especially acidic, so it really soaks into the cement (and it doesn't go very far, because so much soaks into the concrete). The concrete color coat is then designed to hold onto the primer and provide a solid moisture barrier. If the old color won't come off, don't worry. Just clean it up as best you can before applying the primer and paint. And, use top name brand paints (like Dunn-Edwards or Sherman Williams). The more expensive products will cover better and may actually be cheaper in the long run (less coats and time to paint).

- Q:I am taking a chemistry course and i am wondering what purpose quot;PVC Resinquot; serves and how it achieves that purpose?

- i dont know all of the chemistry stuff, but the resin melts the plastic of the pipes, you stick them together, then the plastic from the joined pipes dries, and the pipes are now fused together

- Q:i know it's by adding water but what happenes to it tom make it turn into cement?Thank you!

- First of all its Portland power and then aggregate (rock) and a little sand. when its mixed a chemical reaction occurs and it binds it all together and dries then its cement

- Q:So......I'm a little over my head here. Started taking down wallpaper and wouldn't you know it, there was layer, upon layer and then I accidentially started taking up the backing and came to cement. Have done what I could to salvage what I did, but have decided I'm going to use textured wallpaper over the existing. Do you think it'd be alright to paper right over and on the cement?

- concrete or cement is a porous surface and will not let the glue stick for the long haul. you need to paint the surface with a sealer before you began. a good sealer to use is dryloc. you can pick it up in any paint store or hardware store.

- Q:We started to sand our living room ceiling to get rid of a the texture. When we started sanding, the texture began to chip away. After the texture there is still another layer that became exposed and is is the color grey and is very hard. I have seen drywall and this does not appear to be anything like that. Could it be a cement board? Any suggestions as to how to fix it? Should i do ceiling tiles and leave it? Thanks!!

- That sounds like plaster. Plaster is put on in several layers of different substances. Some can be gray. It can not be cement board, that is way too difficult to work with to put into a living room. It is only used in a bathtub/shower or laundry area. If it not cracked, I would not put in ceiling tiles because I think they look cheesy. You can sand it smooth and paint it or put on new texture. Why did you take the texture off? Was it only because it was chipping off. I have seen paint chip off of plaster after a lot of years. I have also seen some of the various layers of the plaster chip off or even disentegrate. That usually happens after damage over a long period of time. I had a layer of drywall installed over the ceiling on one house for cosmetic purposes. Actually, when I say over, it really was physically under the original ceiling, but we use the term over to denote the fact that there was somthing there already.

- Q:what's the difference between cement and mortor mix?

- Mortar is a material used in masonry to fill the gaps between blocks in construction. The blocks may be stone, brick, breeze blocks (cinder blocks), etc. Mortar is a mixture of sand, a binder such as cement or lime, and water and is applied as a paste which then sets hard. Mortar can also be used to fix, or point masonry when the original mortar has washed away. Cement is in all mortor

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Mid East; Eastern Asia; Western Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Xingang, Jingtang |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Japanese, Russian, Korean |

| b)Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

HCSA Cement 92.5MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 10000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords