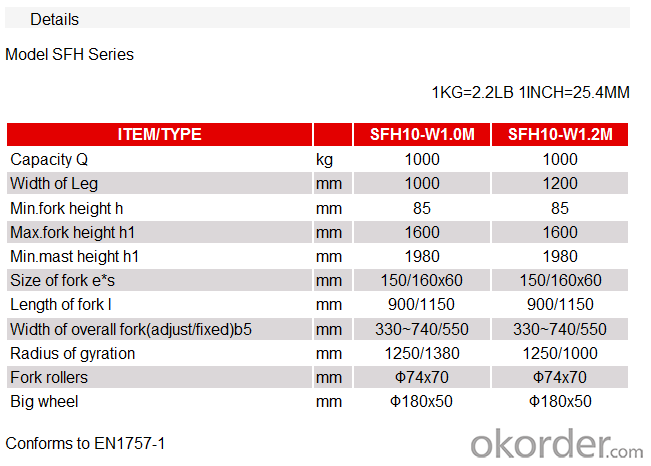

Hand Stacker SFH10-W 1.x M with forklift

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

a stacker has three basic movements:

· Luffing: This is vertical movement. Stackers use either a winch mechanism with metal wire, or hydraulic cylinders, generally two. Winch mechanisms are highly reliable compared to hydraulic actuators and remain widely used, particularly in large stackers.

· Travelling: The stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move around the stockyard as required. For this purpose, traction motors powered by direct current (DC) are connected bybevel gears to between 12 and 22 wheels. For manual control, all the controls are in a controller's cabin above the boom conveyor or boom. Modern stackers can be controlled remotely.

· Slewing: This is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear. The axles may be multiple and are driven by DC-powered axle motors which transmit the torque via bevel or helical gears.

The conveyor belts used in stackers may be made of fabric or metal wire, depending upon the material to be handled. They are driven by pulleys, which in turn are driven by DC motors. The motors and gear are coupled by fluid coupling.

- Q:The forklift truck can't be combined for a license

- No, the loading machine belongs to the engineering machine, the forklift truck belongs to the logistics machinery, different industries.

- Q:Does anyone know what is the principle of explosion protection forklift truck?

- Now domestic explosion-proof forklift is flameproof, now few formal manufacturer, production of explosion protection forklift truck must have a certificate of approval, as Watson electric cars are doing it, you can baidu once,

- Q:I want to learn about the forklift truck. I don't know how well the forklift man works.

- Find a job that is easy to find, and go to the feed factory. At least 3,500 in January, there are five to six thousand, and I did it at the feed factory. You can also go to the electronics factory, but the salary may be more than 3, 000, but it's fun and easy. The answer can help a friend's words, thanks

- Q:For what occasion is a forklift solid tire and pneumatic tyre

- If the quarry rocks and other bad sites are made of solid tires, you are not afraid to wear a flat tire! The pneumatic tyre is light and flexible, but the tyre is too scared to wear, so it is suitable for the warehouse, the factory and the asphalt road.

- Q:What about the steering wheel of an electric forklift without stepping on the accelerator?

- This is normal because there is a switch on the accelerator to open the low speed hydraulic pump.

- Q:What is the engine displacement of 3T forklift?

- Engine Displacement is the total volume of Engine Displacement, the product of Vh and number of cylinders. The cylinder work volume refers to the volume of gas that the piston has swept from the top to the bottom, which is also known as the single cylinder, which depends on the diameter of the cylinder and the stroke of the piston.

- Q:Which is better, solid forklift tyres and inflatable forklift tyres?

- Cons: tires are harder and harder to bump Like, the installation is troublesome, the process is much, if the installation is not good still can cause the tyre and the rim to skid.

- Q:What is the tonnage of a few tons of forklifts?

- There are more than 10 tons of forklifts in the harbor, as well as the container size forklift. The standard forklift truck is usually one ton, two tons and three tons. Special choice in addition to the standard forklifts, forklift with a container for container operations, points into the tank container forklift forklift (2 ~ 5 t), the empty container stacking forklift (7 ~ 10 t) and a tank full of loading and unloading container forklift (20 ~ 42 (t). Each rating of the forklift truck crane quality refers to the cargo weight within the standard load center distance forklift, forklift truck door frame, vertical lifting by forklift standard lifting height (hoisting height provisions in China standard is 3000 mm) when lifting the quality of the goods. User when choosing forklift tonnage, therefore, should be based on the center of gravity of the loading and unloading goods compared with the size of the forklift truck standard load center, such as cargo center of gravity is equal to or less than the standard forklift load center distance, is the selected forklift lifting quality rating equal to or higher than the goods quality. If the center of mass of the cargo is greater than the standard load center of the forklift truck, the loading curve of the forklift truck will be determined according to the loading curve of the forklift truck.

- Q:The forklift card has been tried for several years

- First before take an examination of forklift license to drive a forklift, through formal training institutions for training, and reported by the training institutions materials by the municipal bureau of safety personnel assessment of drivers, can be obtained by theoretical and practical operation test forklift license.

- Q:The forklift oil cylinder is leaking, and the newly replaced oil seal is no good

- The hydraulic control one-way valve in the oil road has a problem. Replace it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hand Stacker SFH10-W 1.x M with forklift

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords