Halogen Free Flame Retardant Thermoplastic Elastomer Compound for Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

plastic granules:

Halogen Free Flame Retardant TPE Compound used for power cable

plastic granules: 1, Type and application: Used for Japanese standard power cable and electrical equipment cable

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than one month. 4, Storage and transport Packaging:20kg/bag,Aluminum foil and PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: |

Item | Unit | Typical | |||||||

E3685A | E3688B | E3690A | E3692A | E3692B | E3689A | ED3685 | EA3685 | ||

Density | g/cm3 | 1.11±0.03 | 1.09±0.03 | 1.14±0.03 | 1.08±0.03 | 1.10±0.03 | 1.10±0.03 | 1.10±0.03 | 1.10±0.03 |

Hardness | Shore A | 85±3 | 88±3 | 90±3 | 92±3 | 92±3 | 89±3 | 85±3 | 85±3 |

Melt Index 230℃×5kg | g/10min | 1.2 | 2.6 | 1.1 | 1.0 | 0.8 | 1.5 | 1.3 | 2.0 |

Tensile Strength | MPa | 15 | 12 | 13 | 16 | 13 | 14 | 12 | 11 |

Elongation at Break | % | 280 | 260 | 250 | 270 | 260 | 260 | 240 | 300 |

Thermal aging | ℃*h | 136℃*168h | |||||||

TS retention | ≥75% | 97 | 99 | 101 | 102 | 101 | 97 | 99 | 109 |

EB retention | ≥75% | 83 | 81 | 79 | 82 | 80 | 81 | 82 | 78 |

Hot deformation | ℃*h | 150℃*1h | |||||||

Variation | ≤50% | 15 | 13 | 12 | 8 | 6 | 9 | 7 | 38 |

pH of gases evolued | -- | 6.3 | 6.5 | 5.3 | 5.6 | 6.2 | 5.6 | 5.5 | 5.3 |

Conductivity of Gases evolved | ≤μm/mm | 1.4 | 1.3 | 1.5 | 1.2 | 1.1 | 1.2 | 1.0 | 1.3 |

Oxygen index | O2 % | 26 | 27 | 27 | 27 | 26 | 27 | 27 | 27 |

Impact Brittleness Temperature | -60 ℃ | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

Volume Resistivity, at 20℃ | Ω﹒m | 3.7×1014 | 3.5×1014 | 4.3×1014 | 3.5×1014 | 3.2×1014 | 4.1×1014 | 4.3×1014 | 5.4×1014 |

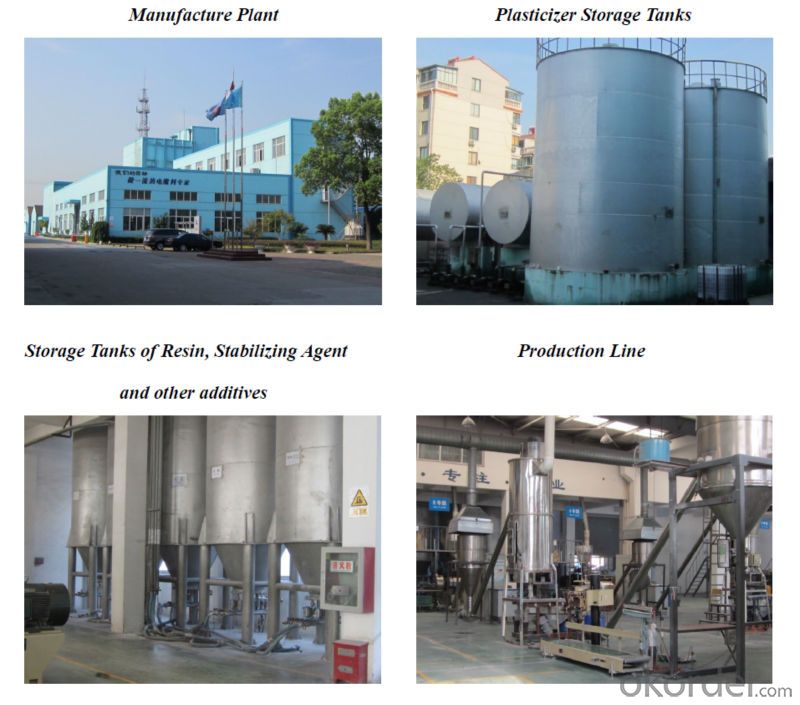

6. Company

- Q:PVC what is the difference between raw and recycled raw materials?

- Raw raw materials, such as rubber oil from rubber trees, are extracted from recycled products and recycled materials are recycled materials.

- Q:What is the difference between plastic particles and raw materials?

- Special plastics: thermosetting plastics, functional polymers, plastics, such as artificial kidney. Heart. Blood vessel。 Aerospace industry, etc.

- Q:How many kinds of raw materials are produced by wrapping plastic film?

- Film type: PVA coated high barrier film, biaxially oriented polypropylene film (BOPP) and low density polyethylene film (LDPE), polyester film (PET), nylon film (PA), polypropylene (CPP) film, etc..

- Q:What kind of raw material is plastic hollow board made of?

- Hollow plate can be divided into anti-static hollow board, hollow conductive plate, ordinary hollow board three categories, anti-static hollow board is mainly used in electronic components on the packing, in order to avoid contact with other charged objects, causing parts for electric spark friction. Anti static hollow board is a new kind of plastic hollow board packing material. Antistatic hollow board mainly replaces ideal environmental protection material, such as corrugated board, wood board and metal plate.

- Q:What are the properties of plastic material PS? What are the advantages and disadvantages?

- Amorphous material, moisture absorption is small, do not have to be fully dry, not easy to break down, but the coefficient of thermal expansion is large, easy to produce internal stress. Good liquidity, can be used screw or plunger injection molding machine

- Q:Main ingredients and formulations of PPR tubes

- PP-R (polypropylene, random) tubes are also called type three polypropylene tubes and also called random copolymerized polypropylene tubes or PPR tubes. The main component is polypropylene three. The formula is different for each manufacturer. This ratio requires manufacturers to do experiments many times before they can be certain.

- Q:Plastic raw materials are granular, why not powder?

- The powder is too choking! Add water to influence the effect of the product!

- Q:What are the raw materials for producing plastic bowls and cups?

- PE, the name at noon is polyethylene. Insoluble in water, slightly soluble in hydrocarbons, toluene, etc.. Resistance to most acid and alkali erosion, water absorption is small, at low temperatures can still maintain flexibility, high electrical insulation. Plastic cups are basically made of PE. Maybe it's because the cup doesn't have the higher requirements of the bowl, and PE is generally cheaper than PP.

- Q:What are the specific differences between plastics and plastics?

- General characteristics of plastic raw materials (LC plastic raw materials wholesale, high temperature resistant plastic materials, PPS, LCP, PET, PA, PES plastic raw material suppliers):1) the plastic material is heated and compressed, and the coefficient of linear expansion is much larger than that of metal;2) the stiffness of a general plastic material is one order lower than that of the metal;3) the mechanical properties of plastic raw materials will decrease obviously when heated for a long time;4) the general plastic material is temporarily subjected to stress at normal temperature and below its yield strength, and permanent deformation occurs;5) plastic raw materials wholesale, sensitive to notch damage;6) the mechanical properties of plastic raw materials are usually much lower than those of metals, but some composite materials have higher specific strength and specific modulus than metals. If the products are properly designed, they will be more effective;7) the mechanical properties of reinforced plastic raw materials are various;8) some plastic materials absorb moisture and cause changes in size and properties;9) some plastics are flammable.

- Q:What is the raw material for producing corn starch plastic film?

- At present, China's maize production in 1.31.5 million tons, only 1/10 of the corn crop is processed into starch, used in the textile industry, paper industry, food industry, medical industry and other fields, the total amount of nearly 10 million tons of starch (including corn starch close to 9 million tons; 420 thousand tons of cassava starch, potato starch, 240 thousand tons).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Halogen Free Flame Retardant Thermoplastic Elastomer Compound for Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords