H20 Timber Beam Formwork with Single Side Bracket for Retaining Wall

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

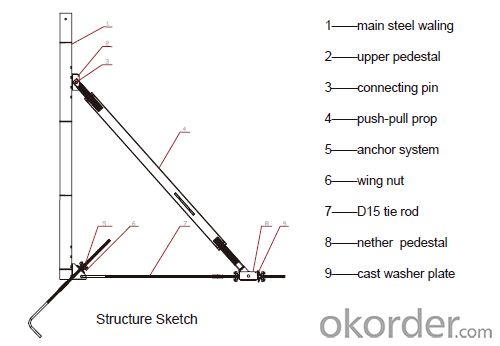

1. Structure of H20 Timber Beam Formwork with Single Side Bracket

During single-sided concrete wall construction, the concrete pressure is transferred into the sub-structure by means of the single-side bracket.

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2 can resist the rising force. R can not only bear the gravity force of the bracket, but also the side pressure of the concrete. This stress system is simple, reasonable and also with convenience and high safety.

2. Main Features of H20 Timber Beam Formwork with Single Side Bracket

1. The pouring height is up to 8.0m and the allowable pressure from fresh concrete is up to a maximum of 60KN/m2.

2. Good standard performance and versatility.

3. Fast element coupling, all units can be quickly connected.

4. The finished wall is excellent and absolutely waterproof.

5. Optimized sizes for transportation.

3. H20 Timber Beam Formwork with Single Side Bracket Images

4. H20 Timber Beam Formwork with Single Side Bracket Specification

5. FAQ of H20 Timber Beam Formwork with Single Side Bracket

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in H20 Timber Beam Formwork with Single Side Bracket, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of H20 Timber Beam Formwork with Single Side Bracket, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:How long does the width of the template support more than how much height the beam can not be poured at the same time?

- Tool-based template works: including sliding mode, climbing mold, flying mold works. Concrete template support works: erect height of 8m and above; erection span of 18m and above; construction of the total load of 15kN / m2 and above; concentration line load 20kN / m and above.

- Q:Construction side without approval without authorization after removal of pouring with the template, what kind of remedial measures should be taken Thank you!

- Do not remove the template, but in the template design and erection must be considered in the post-pouring stand alone erection in order to facilitate the future beam, board concrete to a certain strength after the other full scaffolding removed, leaving the part of the back with the template and support. (Theoretically requires beams and plates of concrete strength to reach 100% to be removed). So that the support design of the post-pouring zone takes into account that the value of the load must meet the requirements of this part to support the independent composite and take the necessary observation and maintenance measures for the template and support. This approach allows the concrete at the post- The template is disturbed, resulting in adverse damage to the structural requirements of the bad.

- Q:What is a template for pulling bolts

- The structure of the bolt is used to connect the concrete component template, also called the pull screw!

- Q:Template support product features

- The light rod is not only the material, but also more flexible and flexible, fastener is a must. Compared to wooden beams, the building structure is more precise and firmer. So that the construction site beautiful and tidy, greatly enhance the corporate image, highlight the strength of enterprises.

- Q:Does the template support of the beamboard contain the full red scaffolding under the beam?

- Of course, according to theory, this full house is not a scaffolding shelf, is the template bracket.

- Q:Template Support System Safety Control

- Template support system must strictly implement the relevant provisions of the national standard, take a sound and reliable security technical measures, and completely eliminate the template support system collapse occurred. Scientific management and advanced technology is to do a good job of template support system effective guarantee, to rely on scientific management and technology, can really control the template support system strength, stiffness and stability

- Q:What is the difference between a full-screen stent and a floor-mounted stent?

- Floor support the fulcrum is the ground, that is, at least to ensure that the ground to do hardening, the local at least can withstand the support of the vertical bar pressure (pressure), and the impact of foundation settlement. The floor is mounted on the floor, although the floor is reinforced concrete (already hardened), but still to prevent the floor under the action of the deformation (vertical deflection) to produce stability problems.

- Q:There are experts to demonstrate the high-support model, the template support frame erected there is no requirement must be held by the shelves of special operations card can be erected carpenters can not erect a search

- The official answer: must be held by the shelter of the special operations card can be set up. You whatever the outcome, but also find some skilled shelves to do this work ah, woodworking bad

- Q:How to use template support?

- This picture is marked on the non-adjustable support, and now generally use adjustable height support.

- Q:400 thick concrete roof template support system need expert demonstration?

- No need. Because 400mm thick is very common, the saying goes to stand the top of the jack - are now steel pipe stent, generally do not support the phenomenon can not afford

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

H20 Timber Beam Formwork with Single Side Bracket for Retaining Wall

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords