H-Frame Scaffolding System with Painting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg/m²

- Supply Capability:

- 10000 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of H Frame ScaffoldingDescription

As a high quality range of Scaffolding Frames-Standard H Frame is being offered to the clients in different specifications. These products have rigid welded frame of horizontal and vertical pipes. Further, these pipes are interconnected by scissor type cross bracings by the help of pins and spring clips.

Packaging & Delivery

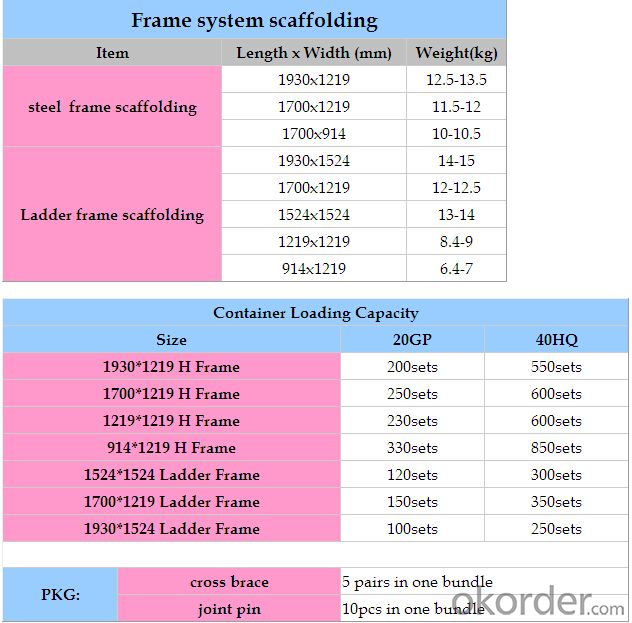

Packaging Detail: | Frame system scaffolding package in the container, or according to your requested |

Delivery Detail: | after deposit 10-15 days |

2. Main Features of Frame Scaffolding

1) Frame system scaffolding is light duty, easy to erect and walk through, wide appciations for both inside and outside constructions.

2)A complete set of frame system scaffolding usually include 2 pcs of H frames ,2 pairs of cross braces and 4 pcs of joint pins.

3) Frame system scaffolding is for inside concrete supporting which can be used with the U Jack to supporting the concrete slab.

4) Frame system scaffolding is also a type of mobile scaffolding that you can install caster wheels at the bottom of frame scaffold ,then frame scaffolding can be moved here and there .

5) Frame system scaffolding can be used for the building decoration which is the light duty scaffolding, it is more easier for moving.

6) Frame system scaffolding are dip painted which means that the inside of the frame scaffolding can be painted to against anti-rustiness

3.Frame Scaffolding product pictures:

4.Frame Scaffolding Product Description

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1)Can we provide different size of Frame system Scaffolding as customer need

The answer is Yes, customer can provide the Tec spec to us and Drawing for production.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q:would a scaffold piercing look gay on a guy?

- i guess it depends on what you look like.

- Q:What are the requirements for the construction of the scaffold eye in the building?

- Optimistic, the most comprehensive!5.2.5 scaffold EngineeringA. accessories(1) selection and calculation basis of structural parts

- Q:Any advise on nerves? I have 11 piercings but I'm still terrified of needles! Any tips on keeping my cool?

- I got my industrial two days ago and it was my first piercing besides the standard lobes and i heard it hurt the worst of all the ear piercings and u have 11? Lol if I could do it u can do it lol I was soooooo nervous and then it just happened and not gonna lie it hurt a lot lol but what I did to distract myself I just talked really loud about the pain lol I was like O MY GOD IT HURTS SO BAD lmao and now it's a lil sore but ull be happy with the results :D

- Q:Okay, quick question. I dropped into a couple of piercing studios yesterday to inquire about getting a scaffold done. Both places informed me that it's not a good idea to have it pierced with a bar straight off, as the pressure from the jewellery combined with the swelling when first pierced can seriously slow down the healing rate. Is this true? The second place said they will pierce both holes with rings, and these can be changed to a bar after around 6 to 8 weeks.Is this the best option? Thanks for any replies.

- That is true, but it's an even worse idea to have an industrial done with rings. This is because your body can move your piercings slightly, to accommodate the angle that works best for your body. In general, that's not a bad thing, but with industrials, it's a problem. You may find that an industrial healed with rings may not accommodate a bar well; the piercing may heal unaligned, and wearing a bar could be painful or impossible. Plus any shop that thinks changing from rings to a bar at 6 to 8 weeks will make any difference from getting a bar initially, you shouldn't trust to poke needles in you. Industrials take 6 months to a year or more to heal. At 8 weeks, the piercings are still very much healing. So if you have your jewelry switched at that point, you'll be irritating the piercing, setting back healing, and you'll have to deal with all of the pressure and hypertrophic scarring problems anyway. It basically comes down to this, industrials suck to heal. Bars are hard to heal. But rings will often result in bad industrial placement and alignment. Just get pierced with a bar and deal with the problems as they come. It's still very much possible to heal an industrial, it just takes time, patience, and a really good piercer (and like I said find a better shop, whoever told you it'd work to change the jewelry from rings to a bar at 8 weeks is an idiot).

- Q:The scaffold weighs 204 N and is 3.10 m long. What is the force each rope exerts on the scaffold when the 665 N worker stands 1.00 m from one end of the scaffold? N (smaller force) N (larger force)

- Sum moments left side...(assume worker 1m from left) Right rope = 316.516 Sum vertical.... Left rope = 552.484

- Q:The bottom of the cantilever scaffold must be provided with the sweeping rod

- Product quality certificate and inspection report. Rust must be replaced, not to be used to build the frame.

- Q:I have some scaffolding that I would like to use to build a temporary slide to my swimming pool. The slide I would like to be made out of the side parts which are the ones like rectangles with bars going across them and I have a variety of poles. I would then like to put a slippery tarpaulin on to the frame.But how would I hold the tarpaulin up, because the metal poles will be too short? So that if someone slid down it they would not just burst through the tarpaulin and hit the floor after hitting around five metal poles!

- Why would you even consider something like that? Obviously you kids and your family use this pool, why put them at risk making a temporary slide with scaffolding. Not a good idea.

- Q:Construction scaffolding right angle fastener, rotary fastener, butt fastener weight? There are more than one meter steel pipe?Thank you!!!

- High efficiency of the installation and removal of only bare handed, greatly improve the efficiency of mobile scaffolding assembly and disassembly than the steel pipe frame 1/2 fast time, faster than bamboo scaffolding 2/3 time. Safe and reliable 1 overall performance is good: equipped with a foot board, parallel frame, buckle wall tube, horizontal and cross bar...

- Q:New features of quick dismantling scaffolding?

- Preservative treatment: Advanced electrophoresis paint treatment, both inside and outside the paintCorrosion effect is longer than the traditional painting and painting steel tube life of 5-8 years

- Q:Salt doesn't really make any different when cleaning infact I think it makes more dried skin to get stick on the bar. My side piercing is fine but the one closest to my eye is painful when pushed or touched I think this is because I accidentally sleep on it without realising. It's red but it has no lump around the piercing is it infected or is it just trying to heal?

- The reason why the earring will stick to the skin and dry up because you're using too much salt. Cleaning it with warm sea salt water is the best way to clean your piercing, especially soaking it in a bowl for 5-10 min. Make-up wipes have alcohol in them, which irritates piercings, just stick to salt. H2Ocean is great, it's a little pricey but it has the right salinity and other ingredients essential for healing tissues. It's not infected, it's just irritated because you slept on it. An infection will have pain, lots of swelling, dark yellowish pus, and throbbing. Give it a sea salt soak and the redness and soreness will go away.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

H-Frame Scaffolding System with Painting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg/m²

- Supply Capability:

- 10000 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords