H beam; structural steel;

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

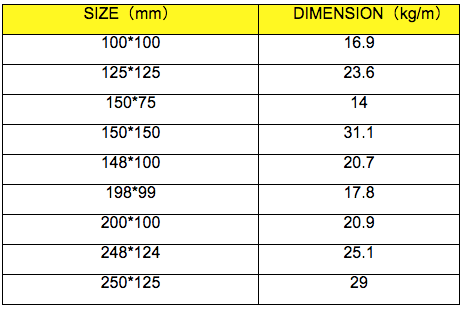

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Structural Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q:Can steel H-beams be used in museum or exhibition hall construction?

- Absolutely, museum or exhibition hall construction can definitely make use of steel H-beams. Their strength, durability, and versatility make them a common choice in construction projects. With their excellent structural support and ability to withstand heavy loads, they are ideal for large-scale structures such as museums or exhibition halls. Moreover, steel H-beams allow for efficient construction as they can be easily fabricated and assembled. Additionally, their sleek and modern appearance can enhance the overall design aesthetic of a museum or exhibition hall. All in all, steel H-beams are a popular and highly favored option for construction in these specific types of buildings.

- Q:Are steel H-beams suitable for structures with architectural features?

- Yes, steel H-beams are suitable for structures with architectural features. Steel H-beams are commonly used in construction due to their strength, durability, and versatility. They provide excellent structural support and can handle heavy loads and high-stress conditions, making them ideal for various architectural designs. Whether it is a building with complex architectural features or unique structural requirements, steel H-beams can be customized and fabricated to meet the specific needs of the project. Additionally, steel H-beams can be easily welded, bolted, or connected to other components, allowing for seamless integration with architectural features. The use of steel H-beams in structures with architectural features ensures stability, safety, and aesthetic appeal, making them a suitable choice for such projects.

- Q:Are there any limitations on the span length of steel H-beams?

- The span length of steel H-beams is subject to certain limitations. This refers to the distance between the supports or columns on which the H-beam is placed. The maximum span length for steel H-beams is determined by several factors, including the type and grade of steel used, the design load or weight the beam must support, and the allowable deflection or bending of the beam. Generally, the span length of steel H-beams can vary significantly. Smaller H-beams with lower load requirements can have longer spans, while larger H-beams with higher load requirements may have shorter spans. Additionally, local building codes and regulations may impose additional limitations on the span length. Structural engineers and architects typically use engineering principles and design software to calculate the maximum span length of steel H-beams. They consider factors such as the beam's moment of inertia, section modulus, and load distribution to determine the appropriate span length for a given application. When determining the span length of steel H-beams for a specific project, it is important to consult with a qualified structural engineer or design professional. They will be able to analyze the specific requirements and conditions and provide accurate and safe recommendations for the maximum span length of the H-beams.

- Q:Can steel H-beams be painted or coated?

- Yes, steel H-beams can be painted or coated. The painting or coating process helps protect the steel from corrosion, improves its aesthetic appearance, and can provide additional durability and resistance to environmental factors.

- Q:What are the different connection methods for steel H-beams?

- There are several different connection methods for steel H-beams, depending on the specific application and structural requirements. 1. Welding: One of the most common methods is welding. H-beams can be welded together using various welding techniques such as arc welding, gas metal arc welding (MIG), or shielded metal arc welding (stick welding). This method provides a strong and rigid connection between the beams. 2. Bolting: Another common method is bolting. H-beams can be connected using high-strength bolts and nuts. This method allows for easy disassembly and reassembly if necessary. It is important to ensure proper bolt size, torque, and spacing to achieve a secure connection. 3. Riveting: Riveting is an older method of connecting steel H-beams, but it is still used in some cases. This process involves drilling holes in the beams and inserting rivets, which are then hammered or compressed to secure the connection. Riveting provides a strong and durable connection, but it is more time-consuming compared to welding or bolting. 4. Moment connections: In structural applications where a high degree of rigidity and load-bearing capacity is required, moment connections can be used. These connections are designed to transmit both shear and moment forces between the beams, providing greater stability and resistance to bending moments. 5. Composite connections: In some cases, steel H-beams may be connected to other materials such as concrete or timber. Composite connections involve combining the properties of different materials to enhance structural performance. This can be achieved by using shear connectors, adhesive bonding, or mechanical fasteners. It is worth noting that the specific connection method chosen will depend on factors such as the load requirements, structural design, available equipment, and the skills and expertise of the construction team. Proper engineering analysis and design are crucial to ensure a safe and efficient connection method for steel H-beams.

- Q:Can steel H-beams be used for shopping centers?

- Yes, steel H-beams can be used for shopping centers. Steel H-beams are commonly used in commercial construction, including shopping centers, due to their strength, durability, and ability to support heavy loads.

- Q:What are the disadvantages of using steel H-beams?

- There are several disadvantages of using steel H-beams in construction projects. Firstly, steel H-beams are relatively heavy compared to other building materials. This can make transportation and installation more challenging, especially in projects that require large quantities of beams. The weight of steel H-beams also adds to the overall load-bearing capacity of the structure, which may require additional reinforcement or support. Secondly, steel H-beams are prone to corrosion if not properly protected. Exposure to moisture and harsh weather conditions can cause rust and structural deterioration over time. To prevent corrosion, additional measures such as galvanization or regular maintenance are necessary, adding to the overall cost and effort. Moreover, steel H-beams are not as environmentally friendly as some alternative materials. The production of steel involves high energy consumption and emits significant amounts of carbon dioxide, contributing to climate change. Additionally, steel is not a renewable resource and requires mining and extraction, which can have negative impacts on the environment. Lastly, steel H-beams have limited design flexibility compared to some other materials. The standard shape and size of H-beams may not always be suitable for certain architectural or structural designs. This limitation can restrict the creativity and customization options for architects and engineers, potentially compromising the overall aesthetics or functionality of the project. Overall, while steel H-beams have many advantages such as high strength and durability, it is important to consider these disadvantages in terms of weight, corrosion, environmental impact, and design limitations when deciding whether to use them in a construction project.

- Q:Can steel H-beams be used in mezzanine construction?

- Yes, steel H-beams can be used in mezzanine construction. Steel H-beams are commonly used for structural support in mezzanine floors due to their strong load-bearing capacity and durability. They provide excellent stability and can efficiently distribute the weight of the mezzanine structure, making them a suitable choice for such construction projects.

- Q:How do steel H-beams contribute to green roof design?

- The role of Steel H-beams in green roof design cannot be overstated. They are essential for providing structural support and facilitating the integration of different components. Essentially, they act as the backbone of the green roof system, ensuring its stability and durability. One of the primary advantages of using steel H-beams is their strength and ability to bear heavy loads. Green roofs, particularly those with extensive vegetation and additional features like water collection systems or rooftop gardens, can be quite weighty. Steel H-beams have the capacity to withstand this weight and distribute it evenly, thus preventing any damage or collapse. Moreover, steel H-beams offer flexibility in terms of design. They can be customized to fit the specific dimensions and layout of the green roof, allowing architects and engineers to create unique and innovative structures. This versatility is crucial for accommodating various green roof designs, whether it's a small residential building or a large commercial complex. In addition to providing structural support, steel H-beams also contribute to the sustainability of green roofs due to their recyclability. Steel is one of the most recycled materials worldwide, making it an environmentally friendly choice. By using steel H-beams in green roof construction, we can reduce the demand for new steel production, conserve resources, and minimize the carbon footprint associated with manufacturing processes. Furthermore, steel H-beams are known for their durability and long lifespan. They can endure harsh weather conditions, extreme temperatures, and UV rays without significant degradation. This durability ensures that the green roof structure will last for an extended period, reducing the need for frequent repairs or replacements. Ultimately, by reducing maintenance requirements, steel H-beams contribute to the overall sustainability of the green roof system. In conclusion, steel H-beams are indispensable in green roof design as they provide the necessary strength and stability, allow for flexible design options, and contribute to sustainability through recyclability and durability. These beams ensure the longevity of green roofs, enabling the creation of sustainable and environmentally friendly urban spaces.

- Q:Can steel H-beams be used in the construction of schools or educational buildings?

- Yes, steel H-beams can be used in the construction of schools or educational buildings. Steel H-beams are commonly used in construction due to their high strength and durability. They provide structural support and stability to buildings, making them suitable for educational facilities that require long-lasting and stable structures. Additionally, steel H-beams can be prefabricated, allowing for faster construction times and cost-effectiveness, which are important factors in educational building projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

H beam; structural steel;

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords