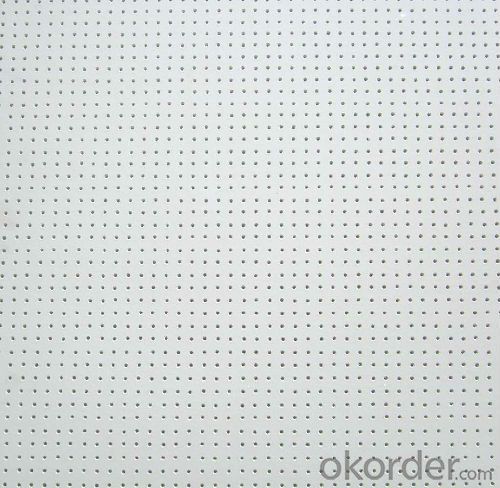

Gypsum Ceiling PVC Laminated 567 Gypsum Ceiling PVC Laminated

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Plasterboard is easy to install, and its decoration effect is good. Its special indoor temperature adjustment function can provide a comfortable living environment. It is the first choice to interior decoration.

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Product Applications:

+ Furred ceiling

+ Interior wall cover

+ Partition wall

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

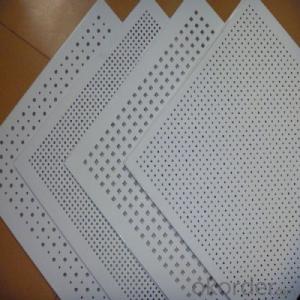

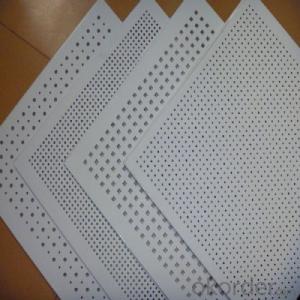

5.Special respiratory function (it has a great mass of ting holes

Product Advantages:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes and its function of moisture-adsorbing and moisture-dismissing)

Main Product Features:

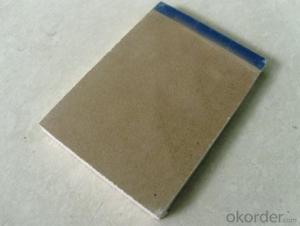

Material: Gypsum Board, non asbestos, sulfate free

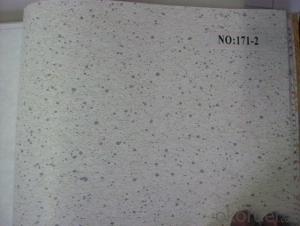

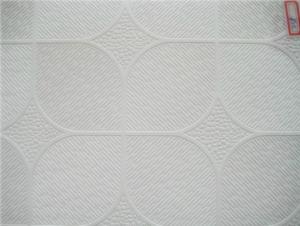

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

Product Specifications:

FAQ:

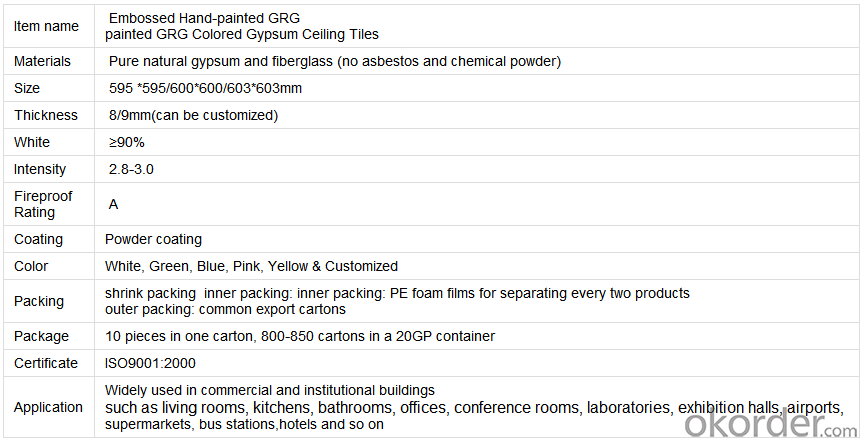

1. What kind of certificate do you have?

ISO9001, ISO14001, CE, SONCAP, VOI(CO), CARB, FSC, CE

2. What color can you produce?

You can choose the design you want

3. How about the delivery time?

20-25 days after receiving prepayment or L/C

For the samples, it will be prepared ASAP.

4. What's the MOQ and Payment Terms?

Minimum Ordering Quantity: 2X20ft Container

Payment Terms: T/T or L/C at sight

Images:

- Q:Gypsum board ceiling how much money a square

- Wood keel slightly more expensive, about 5-8 pieces.

- Q:Light steel keel gypsum board ceiling per square meter weight is how much?

- Gypsum board according to the different thickness of the plate (9.5-25mm), the weight per unit area (9.5-25kg / m2).

- Q:Because I want to change part of the circuit Want to split some living room ceiling The original installed gypsum board ceiling can be demolished? Is it possible to replace it later?

- Can be demolished, but a demolition will demolition of a whole! Can not guarantee that you do not break when the bad Oh. Must buy a new re-installed up.

- Q:Gypsum board ceiling shot hole with what tools drilling, decoration did not give?

- Spotlights to buy no, looking for decoration master hole in accordance with the shooting aperture

- Q:Tangled, is the first to install the ceiling or the first gas water heater installed

- First installed gas water heater, then installed ceiling. 1, the first installation of gas water heater or electric water heater, a boiler is also installed in advance. 2, by the way remind, hood smoke pipe is fixed in advance. 3, the final installation of the ceiling. Ceiling is the roof of the living environment of the top decoration. Simply put, refers to the decoration of the ceiling, is an important part of interior decoration. Ceiling with insulation, insulation, sound insulation, sound absorption of the role, but also electrical, ventilation and air conditioning, communications and fire, alarm pipeline equipment and other projects hidden layer.

- Q:Integrated ceiling benefits and disadvantages?

- Choose the free mix: the integrated function of the ceiling is absolutely independent components, you can according to the kitchen, bathroom size, tile color, their own preferences to choose the required ceiling panel, another heating module, ventilation module, lighting modules are Have multiple choice, free match.

- Q:What is the line on the ceiling? Gypsum carved

- Gypsum line, is the general bedroom with more. Guest restaurants are generally ceiling.

- Q:Is there a need to get a plaster line?

- According to the overall style of the house to determine, in general, the top of the European style gypsum lines more. Other styles do not have to bring;

- Q:Decoration company strongly suggested that with calcium silicate board, said a little bit more expensive than the gypsum board, waterproof fire better than gypsum board, and will not fall off the powder. But I found the Internet, but found that almost no calcium silicate board for the family ceiling, and some calcium silicate board which contains carcinogenic asbestos. And the elderly think that this calcium silicate board, commonly known as cement board, the quality is heavier, hanging on the ceiling always feel insecure, how can I do in the end?

- Asbestos is carcinogenic This you can check online, with carcinogenic asbestos China not to use, in China so that the use of chrysotile asbestos, you can check in Chrysotile on the interpretation of the other do not explain

- Q:House leaking, has been handled well, but the plaster cements are left mildew, how to solve this problem?

- With sandpaper to destroy the black part, re-brush paint

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gypsum Ceiling PVC Laminated 567 Gypsum Ceiling PVC Laminated

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords