Gypsum Board Light Gauge Joist Stud And Track Roll Former Metal Aluminum Drywall Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

1, Production description:metal stud roll forming machine

C channel, stud, track, runner, U channel, Drywall system roll forming machine width adjustable

2, Machine introduction

INTRODUCTION

LMS roll forming machine which takes the COPRA, designing software for cold rolling production and applies for the first step of rolling design, calculation, molding technique simulation, blueprint optimization and roller design to rough molding management, digital machining and quality control. LMS applies for the COPRA in the whole process. The greatness of COPRA is combined with LMS's great experience of twenty years completely and this make LMS be with might double in production for clients. Realize your dream with CORPA.

3, Machine quotation

Quotation: FOB Guangzhou, China.

Roll forming machine(PLC control or common control) Price: will be confirmed after receiving your specification & profile drawing.

Payment term:40% down payment, and 60% balance payment before shipment by T/T.

Delivery time: 75 days after 40% down payment by T/T.

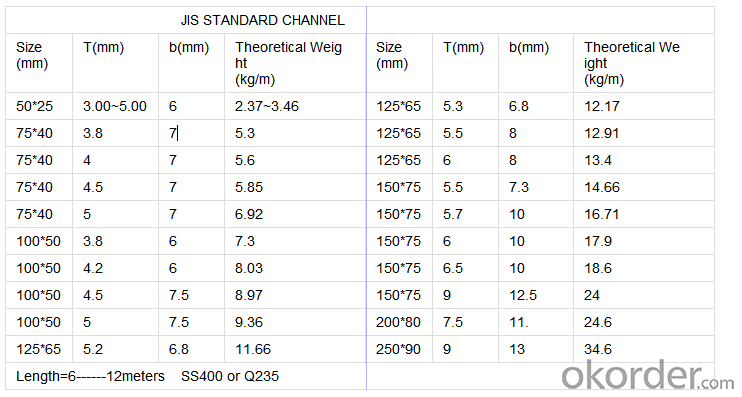

4, Machine specification

Here's the specification for the machine which we made for other clients before, please kindly check for your reference, as well as the photos.

One complete set of production line consist of following units:

Main Technical Parameter:

Thickness:0.45-0.8 mm

Profile width x height:30/60mm x 30mm

3.Image

4.Detailed Specification

5.FAQ

COMPONENTS AND DATA:

A. Decoiler 1 set

Loading capacity: 2 tons

Outer diameter: ?1400mm

Innder diameter: ?400mm-?450mm

Decoiling width: 400mm

Manual expansion

The machine can make more than one sizes: the width is adjustable by using the spacers as indicated in the following photos:

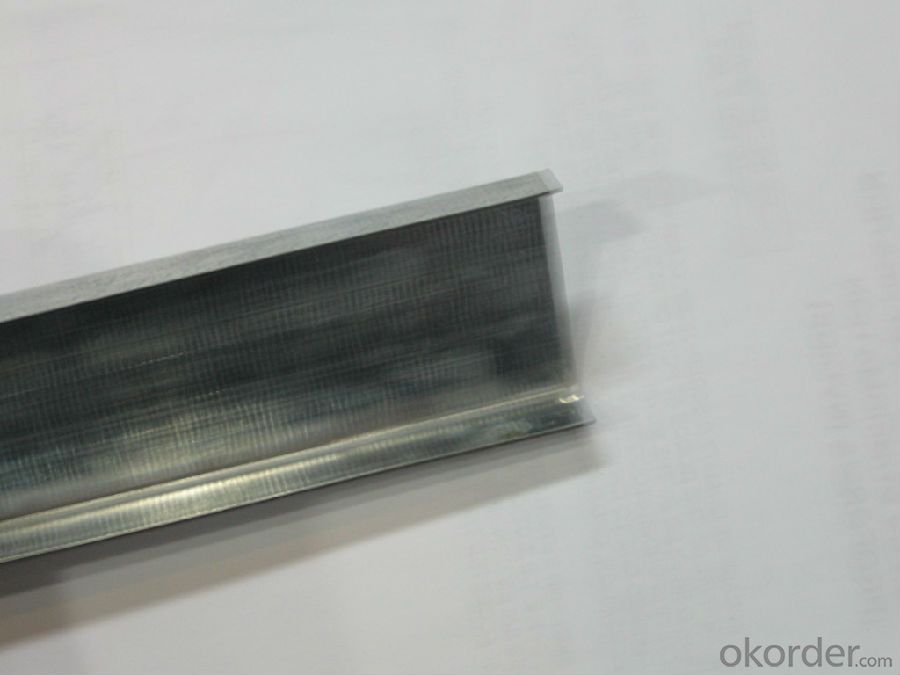

B. Roll Forming Machine 1 set

Roller stations: 14 groups Material of roller: Gr 15 steel

Heat treatment of roller: HRC55-57°

Surface of rollers has been polished.

Material of coil strip: GI,STEEL PLATE

Thickness of coil strip: 0.45-0.8MM

Width of coil strip: ACTUALLY USED

Diameter of roller shaft: ?40mm, made of 45# steel

Pinch wall thickness 22mm

Driven method: Gear and chain

Main bearings: 60207

Bearings thickness 35mm, 45# steel HF surface treatment

Power of main motor: 5.5 kw, cycloid pin reducer

Forming speed: 12m/min

Water coolant system

- Q:Light steel keel gypsum board wall panels have cracks how to do?

- Many reasons caused by the pre-construction time may be the quality of gypsum board is not very good, and there is no wrong between the gypsum board, give you the proposal is to remove all the four sides of the seam, new plaster bandage, putty powder from the new Scrape, otherwise the other method is only a temporary solution,

- Q:How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- First with the expansion bolts fixed heaven and earth keel and roof and the ground, the middle with a vertical keel; if the layer is too high, then the keel will have joints, of course, have special connections.

- Q:Shanghai light steel keel ceiling wall how much labor costs?

- Do not know how much of your area may be a little expensive point of the ceiling 10 yuan / square wall 80 / side less expensive to the point is not the same everywhere, roughly in the 20 to 25 or so labor price.

- Q:Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q:Can the gypsum board be painted on the wall

- If the light can be linked to the screw with a self-tapping screw, hanging 2-3 kg should be no problem

- Q:Home improvement in the partition

- Lightweight brick wall; a brick made of foam cement material, can replace part of the brick wall, reduce the building load, but the high water absorption. Its structure, sound insulation with the red brick wall is almost the same for the indoor simple wall;

- Q:Light steel keel wall in the end is how much money to know

- The partition depends on whether you are single or double-sided single-sided 30 a square double-sided 50 a square called 70 are cut your gypsum board has 13 to 23 blocks have you do partition And not good gypsum board as long as 14 to 15 pieces of gypsum board on it

- Q:Decorative light steel keel paper gypsum board wall height of 4.1 meters span 6.5 meters need not add structural column, beam

- Light steel keel gypsum board wall with a certain distance set by the vertical galvanized main keel, which is made of thin steel plate C-shaped or I-shaped cross-section of the rigid components, the upper and lower ends should have connectors and structures firmly Fixed, do not need to pour concrete construction column. 4.1 meters high has not seen the practice of pouring concrete belt.

- Q:Now what is the room wall material is fashionable? Environmentally friendly

- Now home improvement wall materials are generally light steel keel + sound insulation cotton and light brick wall two, two have their own advantages and disadvantages, brick wall thickness, and space, sound insulation and no sound insulation board is good ; Light steel keel plus gypsum board cut off the knock will be pound, but if it is to consider the bedroom wall after the TV, then the best use of light steel keel + noise cotton, because the hanging must be hanging on the keel, or hanging The In addition, can also be resistant to sound insulation board, thinner board sound insulation effect is better, but the price is relatively expensive. General high noise requirements such as the hotel is used in such a soundproof board.

- Q:The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- With the filling block wall, and the same brick with the nail what is no problem, the weight is not heavy, the thinnest filling block is 120 thick, even the total thickness of double-sided plaster does not exceed 180, or light The partition wall is also the line, faster, but also durable, more than gypsum board wall to spend more, but at least the first nibbling nails are no problem, more durable and reliable, the weight is also light, the normal stay on the trip.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gypsum Board Light Gauge Joist Stud And Track Roll Former Metal Aluminum Drywall Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords