Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

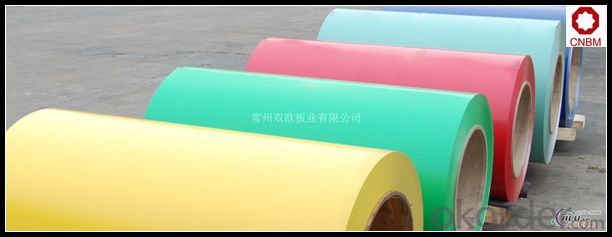

5. Image of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

6. Package and shipping of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum coils be used in the manufacturing of appliances?

- Indeed, the utilization of aluminum coils in appliance manufacturing is possible. Aluminum, renowned for its lightweight and robust nature, is frequently employed in the manufacturing sector due to its exceptional thermal conductivity and ability to resist corrosion. Such attributes render it suitable for an array of applications, including the creation of heating and cooling systems found in appliances like refrigerators, air conditioners, and ovens. In these appliances, aluminum coils are frequently employed to facilitate efficient heat transfer and guarantee optimal functionality. Furthermore, aluminum represents a sustainable option as it is eminently recyclable, thus presenting appliance manufacturers with an environmentally conscious choice.

- Q:How much will be burned out if the soaked and oxidized 5182 aluminum coil is melt down and reprocessed?

- Burn out rate is generally between 1% -2.5%, but that varies among plants as their actual situations are different.

- Q:high-quality hi-fi power and amplifiers generate large amounts of heat. to dissipate the heat and prevent damage to the electronic components, heat-radiating metal fins are used. would it be better to make these fins out of iron or aluminum? specific heat capacities for aluminum and iron are 0.89 J/degrees C.g and 0.45 J/degrees C.g, respectively. explain your answer

- Aluminum has high specific heat than iron which means more energy is require to change aluminum temperature than it of iron. A good conductor is a good emmiter so aluminum will be a best choice since it will not heat up as much as iron for the same amount of mass and energy imput.

- Q:what properties etc makes us use aluminium as the material behind cans...And why does it have the properties?

- For soda cans, it's relatively inert, flexible enough to handle a carbonated liquid, and can be opened without tools. For food, zinc-coated iron or steel is more common. The field that helps you understand why materials have the properties they have is called physical chemistry.

- Q:Related technical standards of aluminium coil

- GB/T 10456-1989 anodized aluminium foilGB/T 9734-1988 chemical reagent -- General method for the determination of aluminiumGeneral specification for GB/T 9538-1988 strip cable connectorsComplexometric titration fluoride release method for the determination of three aluminium oxide content in GB/T 9489.4-1988 corundum powder twoGB/T 9438-1999 aluminium alloy castingsGB/T 8733-2000 cast aluminium alloy ingotsGB/T 6454-1986 getter aluminium zirconium alloy rings and sheets

- Q:What are the standard widths of aluminum coils?

- The standard widths of aluminum coils can vary depending on the specific industry and application. However, in general, the standard widths of aluminum coils range from 12 inches (30.48 cm) to 60 inches (152.4 cm). These standard widths are commonly used in various industries such as construction, transportation, and manufacturing. It is important to note that customized widths are also available in the market to cater to specific project requirements.

- Q:i need to know if Aluminum absorbs radio waves (just the type that control an RC jet)

- Aluminum is a good conductor of electricity. If an object is completely encased in a conductor (forming a Faraday cage), the object will be shielded from radio waves. If the aluminum (or another conductor) covers only part of the object, radio waves may still reach it.

- Q:i dont want aluminum cookware, but how about a stainless steel set with an aluminum core. Is this the same as aluminum pots and pans? Thanks.

- The aluminum is encased in the stainless steel, usually as a thick disk in the bottom. It is an excellent conductor of heat and holds the heat well once it gets hot. All you see is the stainless, none of the aluminum because it's between two layers of stainless in the bottom of the pots. You are right, you don't want food cooked in straight aluminum, some metal taste can transfer to certain foods. That won't happen with stainless.

- Q:Are aluminum coils suitable for architectural cladding?

- Yes, aluminum coils are suitable for architectural cladding. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for exterior applications such as cladding. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, providing designers with flexibility in creating unique architectural designs.

- Q:Are there any limitations to using aluminum coils?

- Yes, there are certain limitations to using aluminum coils. One limitation is that aluminum has a lower tensile strength compared to other metals like steel, making it more prone to damage or deformation under heavy loads or impacts. Additionally, aluminum coils can be susceptible to corrosion if not properly protected or coated. Finally, aluminum coils may not be suitable for applications that require high electrical conductivity, as aluminum has a lower conductivity compared to copper.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords