Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

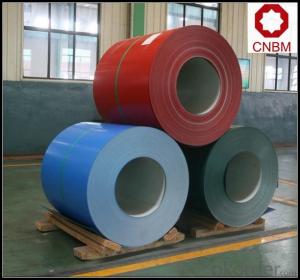

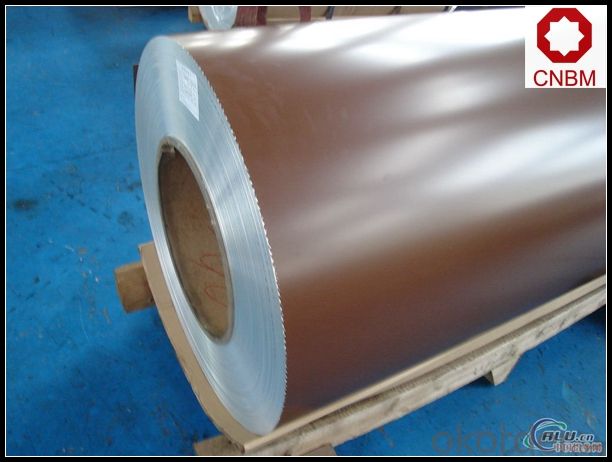

5. Image of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

6. Package and shipping of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How do aluminum coils contribute to the reduction of carbon footprint?

- Aluminum coils contribute to the reduction of carbon footprint in several ways. Firstly, aluminum is a lightweight material, which means that it requires less energy to transport compared to heavier materials like steel. This reduces fuel consumption and emissions associated with transportation, thereby reducing the overall carbon footprint. Additionally, aluminum is highly recyclable and can be recycled indefinitely without losing its quality. The process of recycling aluminum requires significantly less energy (up to 95% less) compared to producing new aluminum from raw materials. By using aluminum coils, which can be easily recycled, we can reduce the demand for new aluminum production, which in turn reduces the carbon emissions associated with the extraction and refining of raw materials. Moreover, aluminum coils have excellent thermal conductivity properties. This makes them highly efficient for use in heating and cooling systems, such as air conditioning units and heat exchangers. By using aluminum coils in these applications, energy consumption is reduced as they facilitate the transfer of heat more efficiently, resulting in lower energy consumption and reduced carbon emissions. Lastly, aluminum coils have a longer lifespan compared to other materials, such as copper or steel. This means that they require less frequent replacement, resulting in reduced waste generation and lower carbon emissions associated with the manufacturing and disposal of new coils. Overall, the utilization of aluminum coils contributes to the reduction of carbon footprint through its lightweight nature, recyclability, thermal conductivity properties, and longer lifespan. By choosing aluminum coils over other materials, we can make significant strides in reducing carbon emissions and promoting a more sustainable future.

- Q:What are some common applications for aluminum coils?

- Aluminum coils are widely used in various industries due to their exceptional qualities and versatility. Some common applications for aluminum coils include: 1. Construction: Aluminum coils are extensively used in the construction industry for roofing, cladding, and insulation purposes. The lightweight nature of aluminum makes it an ideal material for these applications, as it reduces the overall weight of the structure and provides excellent resistance to corrosion. 2. Transportation: Aluminum coils are widely used in the automotive and aerospace industries. In the automotive sector, aluminum coils are used in the manufacturing of heat exchangers, radiators, and condensers. They are also used to produce lightweight body panels, reducing the overall weight of vehicles and improving fuel efficiency. In the aerospace industry, aluminum coils are used to manufacture aircraft parts, including wings, fuselages, and engine components, due to their high strength-to-weight ratio. 3. Electrical and Electronics: Aluminum coils are utilized in the electrical and electronics industry for various applications. They are commonly used in the production of transformers, motors, and generators, as aluminum has excellent conductivity and is lightweight. Aluminum coils are also used in the manufacturing of electrical cables, as they provide good electrical conductivity and are resistant to corrosion. 4. Packaging: Aluminum coils are extensively used in the packaging industry due to their excellent barrier properties. They are commonly used for packaging food and beverages, pharmaceuticals, and various other consumer products. Aluminum coils provide an impermeable barrier against moisture, oxygen, and light, ensuring the preservation and protection of the packaged goods. 5. Heating, Ventilation, and Air Conditioning (HVAC): Aluminum coils are widely used in HVAC systems for their excellent heat transfer properties. They are commonly found in air conditioning systems, heat pumps, and refrigeration units. Aluminum coils provide efficient heat exchange, ensuring effective cooling and heating processes. In summary, aluminum coils find common applications in construction, transportation, electrical and electronics, packaging, and HVAC industries due to their lightweight nature, corrosion resistance, excellent conductivity, and heat transfer properties.

- Q:Can aluminum coils be used for roofing?

- Certainly, roofing can be done using aluminum coils. Aluminum is widely regarded as a top preference for roofing materials because of its sturdy composition, lightweight properties, and exceptional resistance to corrosion. In a wide range of roofing applications, including residential, commercial, and industrial structures, aluminum roofing coils are frequently employed. They offer exceptional safeguarding against severe weather conditions like intense rainfall, snowfall, and powerful winds. Furthermore, aluminum coils possess energy-efficient attributes as they possess the ability to reflect solar heat, thereby aiding in preserving a cool indoor environment and reducing energy expenditures. All in all, aluminum coils present a dependable and enduring roofing solution.

- Q:How are aluminum coils processed for further fabrication?

- Aluminum coils are processed for further fabrication through a series of steps, including cleaning, annealing, leveling, slitting, and recoiling. The cleaning process removes any impurities or contaminants from the surface of the coils. Annealing involves heating and cooling the coils to enhance their ductility and make them easier to work with. Leveling ensures uniform thickness and flatness across the coils. Slitting involves cutting the coils into narrower strips of desired width, while recoiling is done to create smaller coils for specific applications.

- Q:Are aluminum coils easy to bend and shape?

- Yes, aluminum coils are relatively easy to bend and shape due to their malleability and ductility.

- Q:hello, i'm doing a school project on aluminium and i'm a little stumped. what elements bond well with aluminium and why? thanks alot!

- Yes it will be a covalent bond. The simplest compound will be CH4 where each of the electron from the four H will be shared with one each from C to provide 4 covalent bonds.

- Q:Is aluminum silicate roll felt the same as aluminum silicate acupuncture blanket?

- No, the unit weight of aluminum silicate fiber felt is greater than that of aluminum silicate acupuncture blanket. Both are thermal insulation and fire-proof material and have the same function.

- Q:How much is one ton of aluminum coil?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.If you have any questions, please ask. I hope to help you.

- Q:How do aluminum coils contribute to energy-efficient lighting systems?

- Aluminum coils contribute to energy-efficient lighting systems by improving the heat dissipation process. When used in the construction of LED lighting fixtures, aluminum coils help in efficiently transferring heat away from the LED chips, preventing overheating and reducing energy consumption. This improved heat management ensures that the lighting system operates at optimal temperature, thereby extending the lifespan of the LEDs and enhancing overall energy efficiency.

- Q:Why are the aluminum coils sticky after annealing?

- There is oil or the annealing time is too long!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords