Gu10 Spot Light

- Loading Port:

- Guangzhou

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 10 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

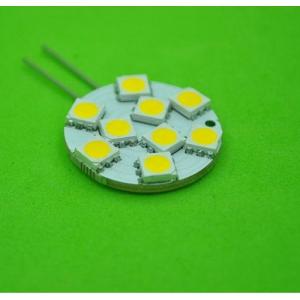

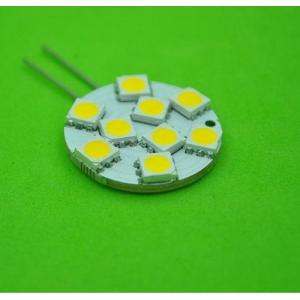

Model: G4 5050 9SMD LED Lamp

Watt: 1.9 W

Angle: 120 °

Voltage: DC10-30 V/50 Hz

LEDs: 9 pc

Color: White or warm white

Lumen: 90 Lm

Abm.: Φ32 mm x 10 mm

Packing: White box

*Constant current, constant voltage

Warranty:1 year

G4 led pack way:

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q:What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- The main difference is the encapsulation method. The liquid silicone is mainly encapsulated and encapsulated, while the gum cake is solid and adopts a transfer molding package. Of course, there is a fundamental difference between the material, silica gel can be used for white light high-power LED, suitable for lighting. The epoxy can only be used in low-power monochrome LED, suitable for display, backlight, induction and other components.

- Q:How many volts is a single LED on the LED patch band?

- LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q:Notes on patch LED

- Storage bags are sealed and stored at a temperature of <40 DEG C.

- Q:Is the forward voltage drop of the patch LED too large or too small?

- Pressure drop does not mean good or bad, the greater the pressure drop, the better to choose the right for you

- Q:Patch LED market conditions

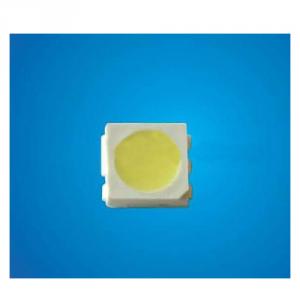

- Conventional monochrome SMD LED package sizes are 1206 (3215), 1004 (2510), 0805 (2012) and 0603 (1608). Chinese manufacturers can provide a minimum size of 0603, the thickness of only 0.3 mm. A smaller LED of 0402 (1005) is still in trial manufacture

- Q:Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q:What is the principle used in SMD LED lamp, should pay attention to what the problem?

- Pin forming, 1, LED pin molding must be completed before welding, bending angle must be more than 3mm of the gel to bend the stent. Pin over 2 times in the same place can not fold number, pin bent to 90 degrees, and then returned to the original position for 1 times; 2, pin forming must use fixture or by professional personnel to complete the first, pay attention to avoid the epoxy body caused by excessive internal wire fracture; 3, to ensure the distance between pin pin forming consistent with the circuit board; 4, when LED has good welding in the welding process or after, please don't bend light feet, to avoid damage to the lamp.

- Q:SMD LED lamp working voltage?

- 18 volts driven high 3030LED lamp (six core series, and 2 core, 3 core series and Design), driving power of up to 1W,1W high voltage 3030 LED (3 volts, 6 volts, 9 volts, 18 volts optional)

- Q:What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The power of the soldering iron should not be too big. Generally choose 20--35 watt welding time as short as possible, it is best to hang the copper wire on the solder, do not use solder paste in the soldering flux, and choose the rosin as well

- Q:What determines the brightness of the patch LED?

- The brightness is consistent over a short period of time, that is, only by considering current and voltage consistency.Long term brightness is consistent with the consideration of the spacing and heat dissipation of different circuits. Uneven heat can also affect brightness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gu10 Spot Light

- Loading Port:

- Guangzhou

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 10 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords