Ground screw piles Mounting Bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

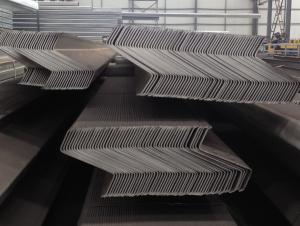

Solar Panel Mounting Bracket

1, mainly used in large-scale photovoltaic power station project, the ground used to support the photovoltaic panels components.

2, product main frame profile is made of Q235B steel plate a cold bending forming, economic, durable, easy to install.

3, surface using hot-dip zinc treatment, durable resistance to corrosion.

4, our products have been in China, gansu, shanxi, shandong, sichuan and other large power station project put into use, obtained the customer consistent high praise.

| Model Number | HL-PS-001 |

| Application | Commercial |

| Installation Site | Open Area |

| Material | Steel |

| Standard | GB,AISI,ASTM,BS,DIN,JIS |

| Installation Angle | According to customer's request |

| Installation Height | According to customer's request |

| Wind Load | 90m/s |

| Snow Load | 1.8KN/m² |

| Solar Panel Size | Any |

| Warranty | 10 years |

| Service life | 25 years |

| Packaging Detail | Standard Export Carton, Plywood Pallet and Case. |

| Delivery Detail | 1-2 weeks according to the order quantity |

Our Services

1. Can provide the customer reference samples

2. Support customized to meet the need of customers design and processing.

3. Provide after-sales construction guidance.

- Q:How does a solar mounting system affect the roof's ventilation?

- A solar mounting system can affect the roof's ventilation by blocking or restricting airflow. This is because the panels are generally installed above the roof, creating a barrier that can hinder the natural flow of air. Proper design and installation of the mounting system are crucial to ensure that adequate ventilation is maintained to prevent heat buildup and potential damage to the roof.

- Q:Fire spray installation in the anti-swing stent approach?

- 4 water branch on each pipe section, adjacent to the nozzle between the pipe set of hanger should not be less than one, the hanger spacing should not be greater than 3.6m.

- Q:How does a solar mounting system affect the roof's maintenance requirements?

- A solar mounting system can affect the roof's maintenance requirements by providing additional protection and extending the lifespan of the roof. The mounting system acts as a barrier between the roof and the solar panels, shielding it from environmental factors like UV rays, hail, and debris. This reduces the wear and tear on the roof and minimizes the need for repairs or replacements. Additionally, the mounting system's design allows for proper ventilation and drainage, preventing any potential damage caused by moisture buildup. Overall, a well-designed solar mounting system can help maintain the roof's integrity and reduce maintenance needs.

- Q:Can a solar mounting system be used in areas with limited access to demand response programs?

- Yes, a solar mounting system can still be used in areas with limited access to demand response programs. Demand response programs are typically designed to incentivize energy consumers to reduce their electricity usage during peak demand periods. While participating in these programs can provide additional benefits and revenue streams for solar system owners, they are not a prerequisite for installing and operating a solar mounting system. Solar energy can still be generated and consumed on-site, reducing reliance on grid electricity and providing cost savings, even in areas without demand response programs.

- Q:Can a solar mounting system be installed on a university or college campus?

- Yes, a solar mounting system can be installed on a university or college campus. In fact, many educational institutions are increasingly embracing renewable energy and installing solar systems as part of their sustainability initiatives. These systems can be mounted on rooftops, parking lots, or open spaces on campus to generate clean and renewable energy, reducing carbon emissions and saving on electricity costs.

- Q:Can a solar mounting system be installed on a summer camp or outdoor education center?

- Yes, a solar mounting system can be installed on a summer camp or outdoor education center. In fact, it can be a great addition to these facilities as it allows for the utilization of renewable energy sources, reducing reliance on conventional energy sources and promoting sustainability. The solar panels can be installed on rooftops, canopies, or ground-mounted systems, depending on the available space and specific requirements of the camp or education center. This installation can not only help to lower energy costs but also serve as an educational tool, teaching campers and visitors about the benefits of solar energy and the importance of environmental conservation.

- Q:How does a solar mounting system affect the roof's insulation?

- A solar mounting system typically does not have a direct impact on the roof's insulation. However, the installation process may require some modifications to the roof, such as drilling holes or attaching brackets, which could potentially compromise the insulation if not done properly. It is essential to hire experienced professionals who know how to install solar panels without causing any damage to the roof's insulation.

- Q:Can a solar mounting system be used with solar-powered electric vehicle charging stations?

- Yes, a solar mounting system can be used with solar-powered electric vehicle charging stations. The solar mounting system helps to securely install solar panels, allowing them to capture sunlight and convert it into electricity. This electricity can then be used to power the charging stations, providing a sustainable and renewable energy source for electric vehicles.

- Q:What materials are typically used in solar mounting systems?

- The materials typically used in solar mounting systems include aluminum, stainless steel, and galvanized steel.

- Q:Are there any fire safety concerns with a solar mounting system?

- Yes, there can be fire safety concerns with a solar mounting system. While solar panels themselves do not typically ignite or cause fires, there are potential risks associated with the electrical components and wiring of the system. Poor installation, faulty wiring, or inadequate maintenance can increase the risk of electrical fires. Additionally, if a fire breaks out in a building where solar panels are installed, it can complicate firefighting efforts due to the potential for live electrical current and limited access to the roof. Proper installation, regular inspections, and adherence to fire safety codes can help mitigate these concerns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ground screw piles Mounting Bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords