Grip Tape with Aluminum Waterproof Anti-Aging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 3000000 m²/month

- Option:

- Aluminum Tape

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Grip Tape with Aluminum Waterproof Anti-Aging

1. Structure of Anti-slip Tape Description

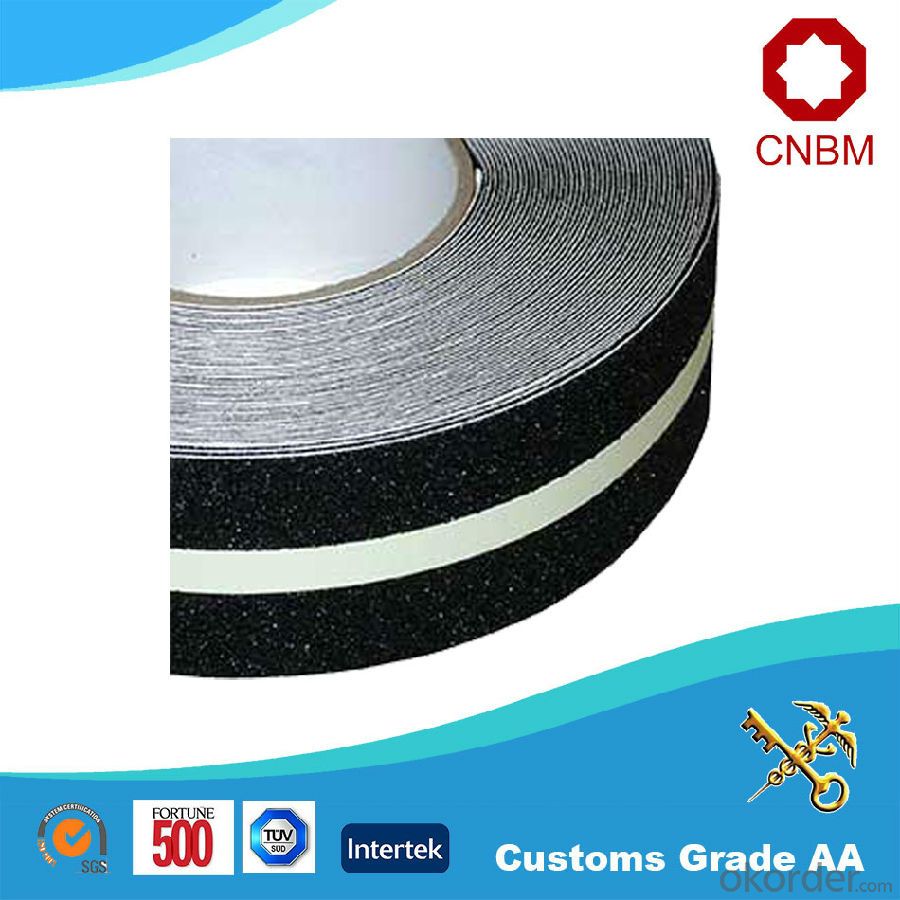

This Anti-slip Tape is of Aluminum as based, ready-to-use waterproof strong viscose as glue. Sticking pads with aluminum bases are recommended to be applied on the irregular arched surfaces.

2. Main Features of Anti-slip Tape

Anti-aging

Good Strength

Irregular Surface

- Printing Patterns

High mechanical strength

Excellent in Adhesion

3. Anti-slip Tape Images

4. Anti-slip Tape Description

Item No. | Carrier | Thickness (c) | Anti-skid sand | Surface granularity |

CN-1107 | PVC film | 25 | black corundum | 40 items |

CN-1108 | PVC film | 9 | silicon carbide | 60 items |

CN-1109 | PET film | 10 | white corundum | 80 items |

CN-1111 | PET film | 5 | silicon carbide | 80 items |

CN-1113 | PP film | 5.2 | white corundum | 100 items |

CN-1114 | PP film | 5.4 | white corundum | 80 items |

CN-1116 | PP film | 5 | white corundum | 60 items |

5. FAQ

Q1. Why choose us?

OEM service, supported by strong R&D team

A short lead time

World Top 500 Enterprise

Quality guarantee with third party certification

One-step service: transportation, capital etc.

Q2. What are the application?

1. sticking pads with PET, PVC, PP bases are recommended to be used on the plane or curved surfaces.

2. sticking pads with aluminum bases are recommended to be applied on the irregular arched surfaces.

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Does packaging tape come in different eco-friendly options?

- Yes, packaging tape is available in different eco-friendly options. Many companies now offer packaging tape made from recycled and biodegradable materials, such as paper or plant-based adhesives. These eco-friendly alternatives help reduce the environmental impact of packaging materials.

- Q:How does packaging tape differ from masking tape?

- Packaging tape and masking tape are distinct types of tapes serving different purposes and possessing unique traits. Specifically intended for sealing and securing packages or boxes, packaging tape finds common use in the shipping and packaging industries. It is typically constructed from robust and long-lasting materials like polypropylene or PVC, ensuring exceptional adhesion and resistance against tearing or splitting. Its notable high tensile strength guarantees the package remains securely sealed during transit or storage. Moreover, packaging tape generally boasts a potent adhesive that adheres well to various surfaces, including cardboard, plastics, and metals. It is available in different widths and lengths to accommodate diverse packaging requirements. In contrast, masking tape primarily finds application in painting and DIY projects. Composed of a thinner and less resilient material, such as crepe paper, it possesses a less aggressive adhesive in comparison to packaging tape. The primary objective of masking tape is to establish clean, straight lines and safeguard surfaces from paint or other liquids during painting tasks. Masking tape can be effortlessly applied and removed without leaving any residue or causing damage to the surface. Furthermore, it is recognized for its ability to conform to uneven surfaces, enabling precise masking and detailing work. To summarize, packaging tape is designed for secure sealing and packaging of boxes and packages, whereas masking tape is primarily utilized for painting and surface protection. Packaging tape is stronger, more durable, and possesses a more potent adhesive, whereas masking tape is thinner, more flexible, and can be effortlessly removed without leaving any residue.

- Q:When the box is sealed, the tape is very noisy and very harsh. What shall I do?

- Silent tape refers to the absence of sound when peeling, which can be used to prevent static electricity

- Q:Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q:Can packaging tape be used for sealing ceramic items?

- Yes, packaging tape can be used for sealing ceramic items. Packaging tape is designed to be strong and durable, making it suitable for securing and sealing various materials, including ceramics. However, it is important to note that packaging tape may not provide the same level of protection as specialized ceramic sealants or adhesives. If you are looking for a more secure and long-lasting seal, it is recommended to use a ceramic-specific adhesive or sealant that is designed to withstand the unique properties of ceramics, such as temperature changes or moisture exposure.

- Q:Is it possible to change the word "one" to "seal"?The origin of "sealing up" and "working"?Is it the result of solving some problems?1., "carton will open the experiment" experimental method. How to verify it?

- Then a new one, according to the above (the specified maximum stacking layers * 1.5) integer layer digital on the product box, standing for 4 hours. If the two experiments are not so that the outer box breaks, your carton is in line with the requirements of the. Note: because there is no standard at all, it represents only personal views, but personal experience.

- Q:The production of transparent tape material is what to do

- In order to obtain better comprehensive performance, the multilayer composite method is usually used in the process of production. BOPP can be combined with a variety of different materials to meet special application needs. Such as BOPP and LDPE (CPP), PE, PT, PO and PVA composite are highly resistance gas, humidity resistance, transparency, high and low temperature resistance, steam resistance and oil resistance, different composite membrane can be applied to oily food, delicious food, dry food, food, cooking cooked food, dipping MSG, pancakes, rice cake and other packaging

- Q:How do I prevent packaging tape from becoming brittle?

- In order to avoid packaging tape from becoming brittle, there are several steps that can be taken: 1. Proper storage is key. Ensure that the packaging tape is stored in a cool and dry location, away from direct sunlight. Extreme temperature fluctuations can lead to tape brittleness, so it is important to maintain a consistent environment to prolong its lifespan. 2. Excessive tension should be avoided when applying the tape. It is best not to stretch the tape too tightly or apply excessive pressure, as this can strain the adhesive and cause it to lose flexibility, resulting in brittleness. 3. Selecting the appropriate tape is essential. Different types of packaging tapes have varying levels of durability. Depending on your specific needs, choose a tape that is specifically designed for heavy-duty or long-term use. These tapes often have stronger adhesives and materials that are less prone to becoming brittle. 4. Handle the tape with care during use. It is important to handle the tape gently to avoid unnecessary stress. Pulling or tugging forcefully on the tape can weaken its structure and lead to brittleness. 5. Replace old tape when necessary. If you notice that your packaging tape has started to become brittle or lose its adhesive strength, it is best to replace it with fresh tape. Using old and brittle tape may compromise the security of your packaging, increasing the risk of it breaking or coming undone during transit. By following these preventive measures, you can help maintain the flexibility and durability of your packaging tape, ensuring it remains reliable for your packaging needs.

- Q:Does packaging tape come in different allergen-free options?

- Yes, packaging tape is available in various allergen-free options. Many manufacturers offer packaging tapes that are specifically designed to be hypoallergenic and suitable for individuals with allergies or sensitivities. These tapes are typically free from common allergens such as latex, gluten, and certain chemical irritants. It is important to check the product description or contact the manufacturer to ensure that the packaging tape meets your specific allergen-free requirements.

- Q:Does packaging tape have a specific weight capacity?

- Yes, packaging tape generally does not have a specific weight capacity as it is primarily used for sealing and securing packages rather than providing structural support.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grip Tape with Aluminum Waterproof Anti-Aging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 3000000 m²/month

- Option:

- Aluminum Tape

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords