Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature of Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

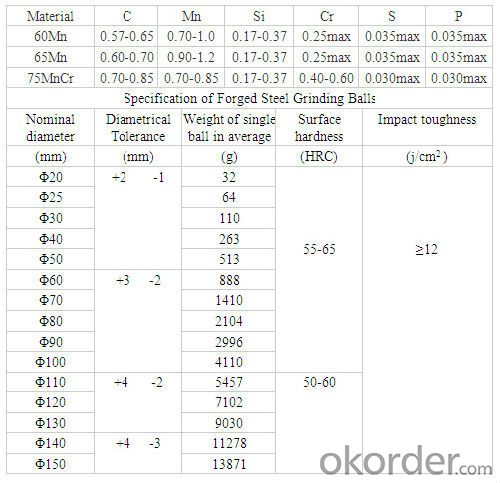

1) In general, grinding steel ball has high hardness: surface hardness to 58-65 HRC, volume hardness of 56-65 HRC

2) impact toughness high: impact toughness more than 12 J / cm2.

3) broken rate is low: the actual broken rate is not higher than 0.5%.

4) loss of grinding forged steel ball round rate is low.

Applied fields of Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

1) Metal Mines, 2) Cement plants, 3) Water coal slurry,

4) Power stations 5) Chemical industry

Chemical Elements of Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

Product and Package of Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

- Q:What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The types and uses of foundry sand according to the mineral composition of different silica sand and non siliceous sand is divided into two categories. The main mineral composition of silica SiO2.: natural silica sand used for non-ferrous metal casting, cast iron and steel castings in small sand and core sand. The selection of natural silica sand: used in organic matter as the binder of various sand and core sand. The artificial sand for sand and core sand castings. Non siliceous sand and non siliceous sand have many kinds and different uses. Limestone sand: crushed by limestone, the main mineral composition is CaCO3, used for casting sand and core sand. Zirconium sand: the main mineral composition is ZrO2 SiO2, used for large steel castings and alloy steel pieces of core sand or sand surface sand, or powder used as coating. Magnesia: the main mineral composition is MGO, used for high manganese steel casting surface sand, core sand, and its powder can be used as coating. Chromite ore: the main mineral composition is chromite FeO. Cr2O3, used for large or special casting steel surface sand, core sand, its powder can be used as coating.

- Q:Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q:How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q:What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q:Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- This is difficult to say, the key is to see the specific parts and components, the final mechanical performance requirements.For example, gray cast iron, usually graphite annealing, to heat treatment annealing, surface quenching and so on, ductile iron can be a variety of annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical treatment and so on, in a word, heat treatment of steel can usually, nodular cast iron can do. Malleable cast iron and vermicular cast iron are often subjected to graphitization annealing and stress relieving annealing, while wear-resistant cast irons often undergo quenching + low temperature tempering, and so on.Welding is the case, such as bearing steel welding must be quenched + low temperature tempering, machine spindle welding (repair welding) must be quenched and tempered treatment, and so on. Of course, if it is a general weld, there is no need for heat treatment or, at most, stress relieving annealing.

- Q:How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- Yantai five God casting is generally 53 yuan /kg, the appearance is quite beautiful

- Q:Cause of choking of casting parts

- Choke fire is the process of pouring a large number of gases can not be discharged smoothly, boiling in the metal liquid, resulting in a large number of castings in the pores, and even incomplete casting defects

- Q:When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q:How to distinguish the forging parts and casting parts accurately

- Distinguish from performance:The processing performance of forged parts is higher than that of the same material. The forging parts are compact and have good mechanical properties, but the casting parts may have sand holes, holes, shrinkage holes and other defects, and their mechanical properties are inferior to those of forgings. At the same time, forging processing can ensure the continuity of the metal fibrous tissue, fibrous tissue to forging and forging shape consistency, metal streamline integrity, can ensure the parts with mechanical properties and long service life good.

- Q:What are the general technical requirements for casting parts?

- What kind of casting do you want to know? Copper parts, iron pieces, aluminum pieces??? Their casting conditions are different.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1971 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Domestic Market, Southeast Asia, South Asia, North America, South America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Korean |

| b)Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Forged Grinding Ball,Cast Grinding Ball,Casting Cylpebs,Grinding Rods,Decorative Steel Ball |

| Product Price Range | Average |

Send your message to us

Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords