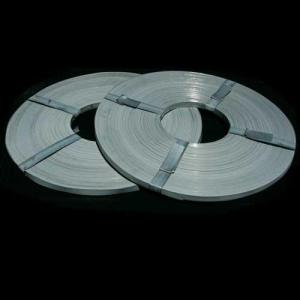

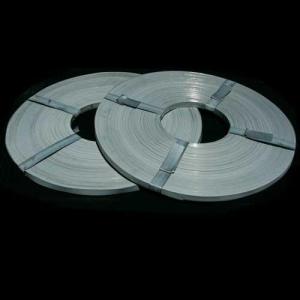

Grey Silane XLPE Compound for 10KV and Below Aerial Hanging Cable with Monosil Method

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000kgs kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Grade 4255G is silane XLPE compound with monosil method (one step), it is specially used for 10kv below aerial hanging power cable, it is composed by selected PE resin, gray anti-ageing masterbatch and other additives. The product’s major characteristics are

◆Outstanding anti-ageing property

◆Outstanding electrical property

◆Simple processing technique

Standard

After crosslinked in the tepid water, the cable made from the product grade 4255G can comply with the standard of IEC60502-2004, GB/T14049-2008

Main Properties & Typical Values

Test Items | Unit | Test Method | Standard | Typical value |

Tensile strength | MPa | GB/T1040.3 | ≥13.5 | 18.5 |

Elongation at break | % | GB/T1040.3 | ≥300 | 460 |

Heat ageing properties (Test temperature 135℃, 168hr) Maximum tensile strength change Maximum elongation at break change |

% % | GB/T8815 |

±20 ±20 |

7.2 7.5 |

Heat elongation (200±3)℃x15minx0.2MPa) Maximum elongation change under load Maximum permanent elongation change after cooled |

% % | GB/T2951 |

≤80 ≤5 |

60 2 |

Impact brittle temp. (-76℃) Impact brittle | Failure no. | GB/T5470 |

≤15/30 |

Pass* |

Dielectric Strength | MV/m | GB/T1408.1 | ≥30 | 40* |

Dielectric loss factor 50Hz, 20℃ | -- | GB/T1409 | ≤1×10-4 | 2×10-4* |

Dielectric constant 50Hz, 20℃ | -- | GB/T1409 | ≤2.35 | 2.2* |

Volume resistance (20℃) | Ω·m | GB/T1410 | ≥1.0×1014 | 6×1014* |

Pressure crack test F50 | hr | GB/T2951 | 1000 | Pass* |

Artificial atmosphere ageing properties: Ageing After 42days, Maximum tensile strength change Maximum elongation at break change Ageing after 42days vs. after 21days Maximum tensile strength change Maximum elongation at break change |

% %

% % | GB/T14049 |

±30 ±30

±15 ±15 |

-18 -20

-10 -9 |

Typical values were tested onthe sample strip by squeezing film extrusion and be boiled in hot water at 90℃ for four hours.

*Especially, these typical values were tested by press moulding sample (A and B mixed at percentage of 90:10), under the condition of 180±2 ℃, 15min, and pressure over 15Mpa, then boiled in 90℃ water for four hours.

Recommended Processing Technique

1. Extrusion Equipment

Most extruders for PVC and PE suit for 4255G

The recommended equipment and processing technique is as following.

Ratio of length and diameter 18—25:1

Diameter 45—120mm

Ratio of compressing 1.5—3.5

Ratio of elongation 1:1.0—1:1.5

Filtering mesh 40/60/40

2. Extruder processing temperature and other related settings

Temperature Setting: Specific processing temperature should be based on different equipment and pressing conditions, reference settings are as following:

Feeding Section(℃) | Compression Section(℃) | Measurement Section (℃) | Die head and Mould (℃) |

140~155 | 155~175 | 175~195 | 195~205 |

Die head setting: Tubing extrusion style is recommended.

3. Crosslink

After extrusion and cooling, the cable can be crosslinked by immersed in hot water (90℃) or exposed in low pressure vapour. The time required for crosslink is based on the thickness of the insulation and the coil size, the thicker the insulation and the greater the coil size, the longer the crosslink time required. The crosslink time can be calculated according to the equation of 4hr/mm for 90℃.

- Q:What are the varieties of wire and cable (detailed point)

- Cable regardless of the definition of the number of elements in the definition of a few such as: YJV-3 * 50 + 1 * 16 calculated the number of lines is always a different, different wire rules Model input: bv-2 * 2.5 / bv-3 * 4 (different material), bv-2 * 2.5 + 3 * 4 (the same material)

- Q:Apple phone display cable or accessories not certified how to do

- The control cable transfers the electrical energy from the power distribution point to the power supply lines of the various electrical equipment The rated voltage of the power cable is generally 06 / 1kV and above, the control cable is mainly 450 / 750V The same specifications of the power cable and control cable in the production, the power cable insulation and sheath thickness than the control cable thick

- Q:What machinery is required to make wire and cable?

- Pouring concrete when you can line? Do you clear the problem?

- Q:If you want to sell wire and cable, then what to do in advance to detect? The The The The The

- Wire diameter, conductor resistance, insulation diameter, the thickness of the thinnest insulation,

- Q:IPadmini. The latest version 7.1.1 up in the morning to see the non-stop display this cable is not certified does not support this feature. The The Charger original. Not on the computer charge. The Ask God to answer more

- The problem lies in the charger between the machine, IPAD charging is to a charging protocol to complete, when the IPAD did not receive the agreement signal will be prompted: do not support this accessory, Apple's products have charging protocol, charging Is through the data line in the two lines and IPAD transmission charging protocol signal when ipad received the charging protocol signal after the machine internal charging circuit began to open the internal charging circuit to charge, the problem is to accept the charge signal is not so prompted not to Support, change the line to try

- Q:What is the difference between the WDZ wire and cable, the ZR wire cable and the NH wire and cable, and what kind of wire and cable should be used?

- Do not know why not mislead. The The The The The Fire resistance is IECGBBS6387. GB is the general principle of flame retardant and fire resistant wire and cable, quoted the above criteria.............................................

- Q:How to determine how much wire and cable should be used, the current load and how the corresponding wire, such as 4BV, under what circumstances, YJV240 what circumstances, the load is much more

- Can not be removed, and so on after the first line of fluoride, and then demolition of air conditioning.

- Q:Remove the computer and wash it off. What the motherboard did not move it, that is, the dust of those dust sasses, as well as the other wire of the skin what Sassafras wash, but the computer re-connected to the Internet when the old mistakes . and the lower right corner of the red Fork appears, disappeared after the emergence. The The Said the network cable is not plugged in, but the MODERN that POWER, LINK, LINE, 3 lights are normal display. The The This is how the matter, and just also appeared keyboard and mouse just start the machine can also be used normally, but in a moment to fall, and then plug their plug re-plug the mouse lights can be displayed, but the lights on the keyboard simply do not Bright, restart the computer but good, what is going on? bother. The The I hope the master quickly to help me, and this machine is relatively old ah No problem added: on a machine, just tried to re-create a connection in the network neighborhood, useless more

- Galvanized pipe itself with anti-corrosion coating, you can not do anti-corrosion.

- Q:Wire and cable fire resistance to meet what standards, which can provide about, thank you!

- Should be the line group: lighting a group of 2.5 square millimeters, an ordinary socket a group of 4 square millimeters, air conditioning a group of 6 square millimeters, kitchen and bathroom appliances a group of 4 square millimeters, so that after the down is not enough to put a separate group You say the high-power electrical outlet, the line to the square of the square mm to see your home how high-power electrical appliances, but advise you to use these high-power electrical appliances before the first to determine its current good, More than your home appliance load!

- Q:What are the T and T, s of the wire and cable test type?

- You should be said: 2-way cross-linked polyethylene insulated PVC sheathed cable 4 core 185 square millimeters, SC is steel pipe, diameter . FC is laying method dark cover the floor or floor. Personal opinion, hope to help you!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grey Silane XLPE Compound for 10KV and Below Aerial Hanging Cable with Monosil Method

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000kgs kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords