Grey color back coated aluminum alloy metals

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colorcoated aluminum magnesium alloy Al-Mn

Second, the Al-Mn-Mg alloys thecharacteristics of color coated aluminum

Color coated aluminum magnesiumalloy Al-Mn alloy is used for the 3004 state of the Al-Mn-Mg aluminum alloysubstrate, after de-ester, cleaning, passivation layer processing, and thenpainting on this basis, the international most advanced level of KANAR500 andHYLAR5000 Series Fluorocarbon (PVDF) resin coating, the color coated aluminummanganese alloy known international companies use the U.S. PPG, Sweden and theUnited States Weishi Bo Beca companies paint company, its products by thenatural light exposure, Florida testing, with more than 20 years of weatheringquality assurance. Color coated aluminum magnesium alloy Al-Mn advantages ofraw materials, its products have a high strength, corrosion resistance, highweather resistance and other characteristics, and according to their owncustomers were asked to choose a different color palette, you can colorintegration, can co-exist to gorgeous effect.

Third, Al-Mn-Mg alloys the useof color coated aluminum

Our company specializes inaluminum color coated aluminum manganese alloy has been widely used in largefactories, exhibition halls, stadiums, airports, train station roof and ceilingdecorative envelope system board. Thickness of the aluminum can choosedifferent color coated aluminum magnesium alloy of manganese, by cutting,pressing, punching, bending and other follow-up molding process for large span,the larger the overall roof, wall decorative panels used in construction; Youcan also cut into small panels by bending, stamping mold, etc., for indoordecorative roof plate; also with polyurethane foam, bonded aluminum honeycombcomposite construction for energy-saving decorative wall plates.

Fourth, the development prospects

As the field of buildingdecoration materials, the continuous improvement requirements, as poorperformance of color coated steel corrosion, rust, yellow rust after a largeamount of the deficiency of serious impact on the building's overallappearance, the urgent need to develop a color plate with both strength, butalso overcome the shortcomings of color-coated steel, while there are long-termdurability of new materials, building decoration, used in airports, commercialbuildings, train stations, subways, hospitals and other architecturaldecoration. The Al-Mn-color coated aluminum magnesium alloy materials preciselymeet these requirements, with the expanding domestic demand, strengthen publicinfrastructure under the principle of color coated aluminum magnesium alloy ofmanganese will become an increasingly widespread use of aluminum, a goodprospect.

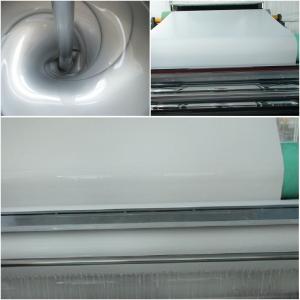

PEAluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1.Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy isavailable with AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof PE Aluminum Coating Coil

Width:20mm~1590mm

Thickness:0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coilweight: ≤ 4000kg

PE coatedaluminum coil is processed through the technics of roller coating and bakingwith precise polyester paints. Its color is glossy and with variety of colorsenabling you to choose easily. Chromatic aberration is small, impact resistanceis strong and easy to be processed, and all its performance has reached orsurpassed the national criteria. The products are widely used in indoor anddoor decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performanceof the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Colorof Card

PE (polyester)

PE

ColorMatch

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q:could you please help me find information of the element aluminum??? all the information i can get will be great... thanks very mucho.... who discovered? where can i find pictures of it?

- hi ive found this: Aluminium is a silvery white member of the boron group of chemical elements. It has the symbol Al and its atomic number is 13. It is not soluble in water under normal circumstances. Aluminium is the most abundant metal in the Earth's crust, and the third most abundant element, after oxygen and silicon. It makes up about 8% by weight of the Earth's solid surface. Aluminium is too reactive chemically to occur in nature as a free metal. Instead, it is found combined in over 270 different minerals.[5] The chief source of aluminium is bauxite ore. Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are very important in other areas of transportation and building. Its reactive nature makes it useful as a catalyst or additive in chemical mixtures, including ammonium nitrate explosives, to enhance blast power. Aluminium is a soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. Aluminium is nonmagnetic and nonsparking. It is also insoluble in alcohol, though it can be soluble in water in certain forms. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[6] Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

- Q:Can aluminum coils be used in telecommunications infrastructure?

- Yes, aluminum coils can be used in telecommunications infrastructure. Aluminum is a lightweight and durable material that is commonly used in various industries, including telecommunications. The use of aluminum coils in telecommunications infrastructure offers several advantages. Firstly, aluminum is a cost-effective material compared to other metals like copper. It is readily available and has a lower price point, making it a preferred choice for many telecommunications companies. Additionally, aluminum coils are lighter in weight, which makes them easier to handle and install, reducing the overall labor and transportation costs. Moreover, aluminum has excellent electrical conductivity, making it suitable for transmitting data signals in telecommunications networks. Aluminum coils can effectively carry electrical current, ensuring efficient data transmission without any significant loss in quality. This conductivity enables reliable and high-speed communication over long distances. Another advantage of using aluminum coils in telecommunications infrastructure is their resistance to corrosion. Aluminum naturally forms a protective oxide layer when exposed to air, preventing it from rusting or corroding easily. This resistance to corrosion ensures the longevity and durability of the infrastructure, reducing maintenance and replacement costs over time. However, it is important to note that aluminum has a lower tensile strength compared to copper. Therefore, proper engineering and design considerations need to be taken to ensure the structural integrity of the infrastructure when using aluminum coils. Additionally, specific connectors and hardware compatible with aluminum may be required. In conclusion, aluminum coils can be effectively used in telecommunications infrastructure due to their cost-effectiveness, lightweight, electrical conductivity, and resistance to corrosion. Proper planning and design are necessary to ensure the successful implementation of aluminum coils in telecommunications networks.

- Q:Can aluminum coils be used in automotive manufacturing?

- Yes, aluminum coils can be used in automotive manufacturing. Aluminum is a lightweight and durable material, making it a suitable choice for various automotive components such as body panels, engine parts, and heat exchangers. Its corrosion resistance and recyclability also make it an attractive option for the automotive industry.

- Q:How do aluminum coils compare to ceramic coils in terms of thermal conductivity?

- Aluminum coils have significantly higher thermal conductivity compared to ceramic coils.

- Q:A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

- Q:What are the different coil diameters available for aluminum coils?

- The coil diameters for aluminum coils can differ based on specific needs and applications. Typically, aluminum coils are offered in various diameters to accommodate different requirements. These diameters can vary from a few inches to several feet. Manufacturers and suppliers may have different options for coil diameters. It is crucial to consider that the chosen diameter will affect factors like coil weight, handling, and compatibility with machinery or equipment. Therefore, it is recommended to consult with suppliers or manufacturers to determine the available coil diameter options for aluminum coils based on intended use and requirements.

- Q:How do aluminum coils contribute to sustainable construction?

- Due to their numerous environmental benefits, aluminum coils play a vital role in promoting sustainable construction practices. One key advantage is the high recyclability of aluminum, with almost 75% of all aluminum ever produced still in use today. This means that at the end of their lifespan, aluminum coils can be easily recycled, reducing the need for new raw materials and minimizing waste sent to landfills. Furthermore, compared to other materials like steel, the production process of aluminum coils requires significantly less energy. This results in a low carbon footprint, as the energy consumed during production is considerably lower, leading to fewer greenhouse gas emissions. Additionally, the reduced energy consumption contributes to lower operating costs for construction projects, making aluminum coils an economically viable choice. Moreover, aluminum coils are not only lightweight but also highly durable, making them an ideal option for sustainable construction. Their lightweight nature reduces the need for heavy support structures, which in turn reduces material consumption and transportation costs. Additionally, the durability of aluminum coils ensures a longer lifespan, reducing the frequency of replacement and minimizing waste generation. Another crucial aspect of aluminum coils in sustainable construction is their excellent corrosion resistance. This resistance means that structures made from aluminum coils require less maintenance and repair over time. Consequently, fewer resources are needed to uphold the building's integrity, resulting in a reduced overall environmental impact. In conclusion, aluminum coils contribute significantly to sustainable construction through their high recyclability, energy efficiency, lightweight yet durable nature, and excellent corrosion resistance. By opting for aluminum coils, construction projects can significantly decrease their environmental footprint, conserve resources, and advocate for a more sustainable built environment.

- Q:What are the compositions of aluminum coil coating?

- The common compositions are crylic resin, solid inorganic filler, different pigments, flatting agent and so on.

- Q:What are the different types of surface finishes for decorative purposes?

- There are several different types of surface finishes that are commonly used for decorative purposes. These finishes can enhance the appearance of a surface, adding texture, depth, and visual interest. Some of the most popular types of surface finishes for decorative purposes include: 1. Polished: Polished finishes are smooth and shiny, creating a reflective surface. This finish is achieved by polishing the surface using abrasive materials, resulting in a glossy appearance. 2. Matte: Matte finishes have a flat, non-reflective surface. They are achieved by using sandpaper or other materials to create a smooth but dull appearance. Matte finishes are often used to create a more subtle and understated aesthetic. 3. Brushed: Brushed finishes have a distinctive linear pattern that is created by brushing the surface with a wire brush or abrasive material. This finish is commonly used on metals, such as stainless steel, to create a textured and visually interesting look. 4. Textured: Textured finishes involve adding patterns or designs to the surface through various techniques. This can include embossing, engraving, or applying a textured coating. Textured finishes can add depth and dimension to a surface, creating a unique and visually appealing effect. 5. Antiqued: Antiqued finishes are designed to mimic the appearance of aged or weathered surfaces. This can be achieved through techniques such as distressing, staining, or adding a patina. Antiqued finishes are often used to create a vintage or rustic look. 6. Metallic: Metallic finishes use metallic pigments or coatings to create a shiny and reflective appearance. This finish can add a touch of elegance and sophistication to a surface, making it a popular choice for decorative purposes. 7. High gloss: High gloss finishes have an extremely smooth and reflective surface, creating a mirror-like effect. This finish is achieved by applying multiple layers of clear coat or lacquer and polishing the surface to a high shine. High gloss finishes are often used to create a modern and luxurious look. Overall, the choice of surface finish for decorative purposes depends on the desired aesthetic and the type of material being used. Each finish has its own unique qualities and can greatly enhance the overall visual appeal of a surface.

- Q:94 f150. have the stock wheels which are weathered and dull. whats a good way to bring the shine back? some of the original coating is there ,most is gone. tried mothers aluminum wheel polish,does nothing. is it wise to use a wire wheel in a drill to get down to just the aluminum? the wheels are those with the center plastic cap with holes around the outer edge.thanks for any info

- Get a couple of those Mothers power balls .If the clear coat is coming off Then dirt is embedded in the rim The best way is to have them polished by a pro .If thats not the route you want to go ,the power ball is about the only thing that can help you out and for much cheaper than having a pro do it .Not to mention doing it by hand just sucks .But it would take two at least to do all 4 wheels Then the polish will do what its advertised to do or use any polish you want You will need to at least remove the wheel off the truck for the best results If you strip the rims or use acidic cleaners to remove the remaining clear coat It may take more materials Like polish ,Pads,or the power ball thing Cause it will leave a raw aluminum surface which usually requires more time and labor to polish out DON'T WIRE WHEEL THE RIMS OKAY YOU WILL SCRATCH THEM SO DEEP YOU WILL RUIN THEM NO ABRASIVE MATERIALS ARE TO BE USED ON A ALUMINUM RIM NOT EVEN A WIRE WHEEL OF ANY TYPE OR MATERIAL SHOULD BE USED ON THE RIM what you'll do is make them uglier Cause pitting strip the surface leaving a porous and uneven surface Which corrosion likes to form on .Thats the worst and the wrong way to clean aluminum and even steel sometimes depending on what it is But NEVER aluminum

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grey color back coated aluminum alloy metals

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords