Greenhouse Usage Plug Trays (Growing and Seedling) HIPS Made Plastic

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction to CNBM:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Features of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Picture:

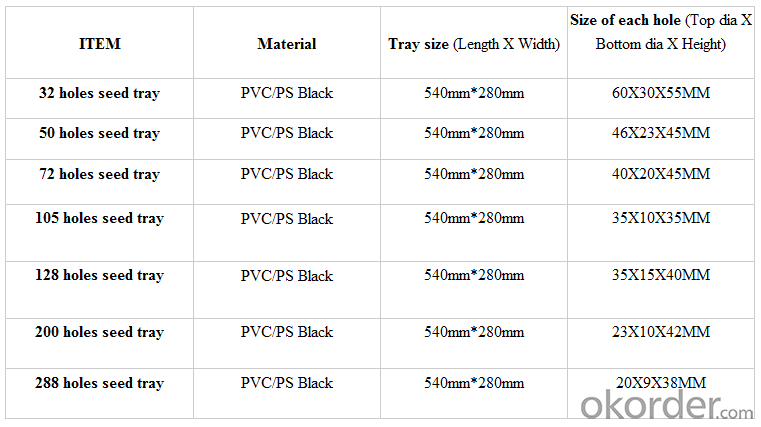

Specification of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

FAQ of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

Q:1.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

Q: 2.How long is the production time?

A: Usually one to two weeks.

Q: 3.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

- Q:How do I choose ground cover for a shady slope?

- When selecting ground cover for a shady slope, it is important to consider plants that thrive in low light conditions and can help control erosion. Opt for shade-tolerant ground covers like English ivy, vinca minor, or pachysandra, which are known for their ability to spread and form a dense mat. Additionally, consider plants with deep roots that can anchor the soil, preventing erosion. It is also recommended to choose native species that are adapted to local conditions. Conducting research, seeking advice from local nurseries or gardening experts, and considering the specific characteristics of your slope (such as soil type and moisture levels) will further assist you in making an informed decision.

- Q:What's the most heat resistant kind of plastic? I'm looking to find out what various pan handles are made out of and kitchen supplies that are meant to withstand high temperatures.

- For the best answers, search on this site https://shorturl.im/avEok heat resistant is their way of saying it's not their fault if something catches fire or melts. Wood floor should be fine, and as long as the top of the fridge isn't made of cheap plastic it should be fine. you could always buy some pot holders (the flat square kind, insulated) and use those as a base.

- Q:Can nursery trays be used for starting vegetable transplants?

- Yes, nursery trays can be used for starting vegetable transplants. They provide a convenient and organized way to germinate seeds and grow young plants before transplanting them into the garden. The trays typically have individual cells or compartments that allow for proper root development and easy transplanting. Additionally, nursery trays help maintain moisture levels and provide a controlled environment for optimal growth.

- Q:Are nursery trays waterproof?

- Yes, nursery trays are typically waterproof. They are designed to hold soil and water without leaking, making them suitable for nurturing young plants and seedlings.

- Q:Can nursery trays be used for herbs?

- Yes, nursery trays can be used for herbs. Nursery trays provide a convenient and efficient way to start herb seeds or propagate herb cuttings. They offer proper drainage, allow for easy transplanting, and help maintain organized and compact growing spaces for herbs.

- Q:can you wear plastic pants without a diaper on in a swimming pool will water leak in

- The answer is, yes, you can wear plastic pants without a diaper if you want, why not? The second answer is, yes, water will leak in around the waist and leg openings if you stay in the water long enough, not to mention, things will leak out for the same reason.

- Q:What is the purpose of agricultural plastic products?

- The purpose of agricultural plastic products is to provide practical and efficient solutions for various farming needs such as crop protection, greenhouse cultivation, irrigation systems, and packaging, ultimately enhancing productivity and reducing environmental impact.

- Q:I'm really confused about this and hopefully someone on here can clear it up for me I'm reading a journal article and one of their procedures confused me. The researchers used a swab on dried saliva and then the swab was mixed in a plastic cuvet containing 2 mL of KCL solution and than the solution in the plastic cuvet was transferred to a quartz cuvet which was then used in a fluorescence spectrometer. My question is, why did they use a plastic cuvet and then transfer it? Why couldn't they used the quartz cuvet directly?THanks so much

- Plastic cuvettes are cheaper than quartz, for one! Did they mix the fluorescent dye in the plastic, too? I'd have to see what they were measuring, but you do know that plastic adsorbs certain materials that quartz will not. Perhaps there was some fraction of the saliva solution that they did not want transferred over. When doing antibody research, we routinely used plasticware to make the antigens stick to the plastic. That is a possible explanation.

- Q:How do you prevent fertilizer runoff in nursery trays?

- One way to prevent fertilizer runoff in nursery trays is by using controlled-release fertilizers. These fertilizers are designed to release nutrients slowly over time, reducing the chances of excess nutrients leaching out of the trays. Additionally, properly managing irrigation practices can help prevent runoff by ensuring that the trays are not overwatered, as excessive water can cause the fertilizer to wash away. Implementing best management practices such as monitoring and adjusting nutrient application rates, timing, and methods can also help minimize fertilizer runoff in nursery trays.

- Q:How do you make paint stick to plastic?

- I'm actually currently in the process of painting my xbox 360 controller I've completly researched that matter. I'm using spray paint, and will be adding coats in this order: Adhesion Promoter, Spray Paint (for plastic), Clear coat. Dupli-color Krylon brands are preferred.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Greenhouse Usage Plug Trays (Growing and Seedling) HIPS Made Plastic

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords