Greenhouse Usage Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction to CNBM:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Features of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Picture:

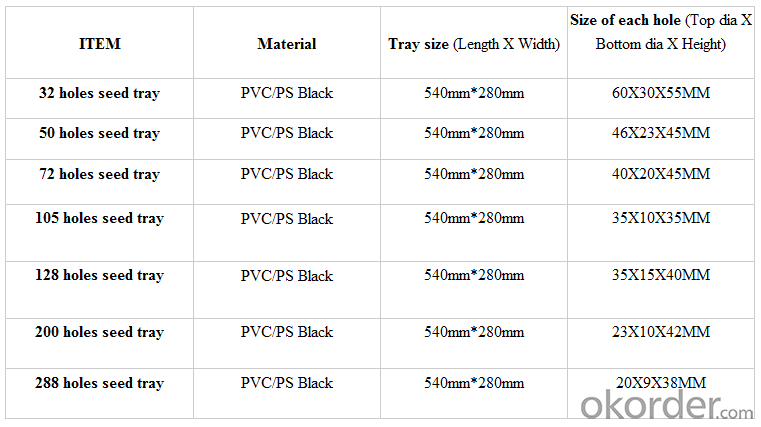

Specification of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

FAQ of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

Q:1.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

Q: 2.How long is the production time?

A: Usually one to two weeks.

Q: 3.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

- Q:Are there any grants or funding available for agricultural plastic products research?

- Yes, there are grants and funding opportunities available for agricultural plastic products research. These can be obtained from various sources such as government agencies, research institutions, foundations, and industry organizations. It is advisable to explore these avenues and thoroughly research the eligibility criteria and application process to secure funding for agricultural plastic products research.

- Q:How do you care for ground cover plants?

- To care for ground cover plants, it is important to provide them with regular watering, especially during dry spells. It's crucial to check the specific watering requirements of the particular ground cover plant as some may need less water than others. Additionally, it's essential to remove any weeds that may compete with the ground cover for nutrients and space. Regular pruning or trimming of the ground cover plants helps maintain their shape and prevents them from becoming overgrown. Finally, applying a layer of mulch around the plants can help retain moisture, regulate soil temperature, and suppress weed growth.

- Q:What are some ground cover plants that tolerate foot traffic?

- Some ground cover plants that tolerate foot traffic include creeping thyme, creeping jenny, ajuga, creeping phlox, and sedum.

- Q:Why plastics are white pollution?

- It refers to polystyrene, polypropylene, polyvinyl chloride and other polymer compounds made of all kinds of living plastic products, used to be discarded as solid waste,

- Q:Do nursery trays come with lids?

- Yes, nursery trays typically come with lids to create a controlled environment for seedlings and young plants.

- Q:plastic housing on car broken epoxy worked for a while

- It called plastic weld it like epoxy but will stay a lot longer I put it on my dirt bike fender and I rode that all sommer in the woods and it stad so got to an auto parts store and ask for epoxy plastic weld it is different the reguler epoxy

- Q:What sizes do nursery trays come in?

- Nursery trays come in a variety of sizes, ranging from small trays with a few cells to larger trays with dozens or even hundreds of cells.

- Q:How do you prevent ground cover plants from competing with other plants?

- One way to prevent ground cover plants from competing with other plants is by creating physical barriers, such as installing edging or borders, to keep the ground cover contained in a specific area. Another method is to regularly prune or trim the ground cover plants to restrict their growth and prevent them from encroaching on other plants. Additionally, proper spacing between plants during planting can help prevent competition for nutrients and sunlight. Implementing mulching around other plants can also suppress the growth of ground cover plants and limit their ability to compete.

- Q:Can ground cover plants be used to improve water retention in soil?

- Yes, ground cover plants can be used to improve water retention in soil. These plants help to reduce soil erosion and increase organic matter in the soil, which in turn improves its ability to retain water. The dense foliage of ground cover plants also acts as a natural mulch, reducing evaporation and keeping the soil moist for longer periods.

- Q:What are the different colors available for agricultural plastic products?

- The different colors available for agricultural plastic products include black, white, green, blue, and transparent.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Greenhouse Usage Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords