Green/White Thickness 2.0mm/3.0mm/4.0mm PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

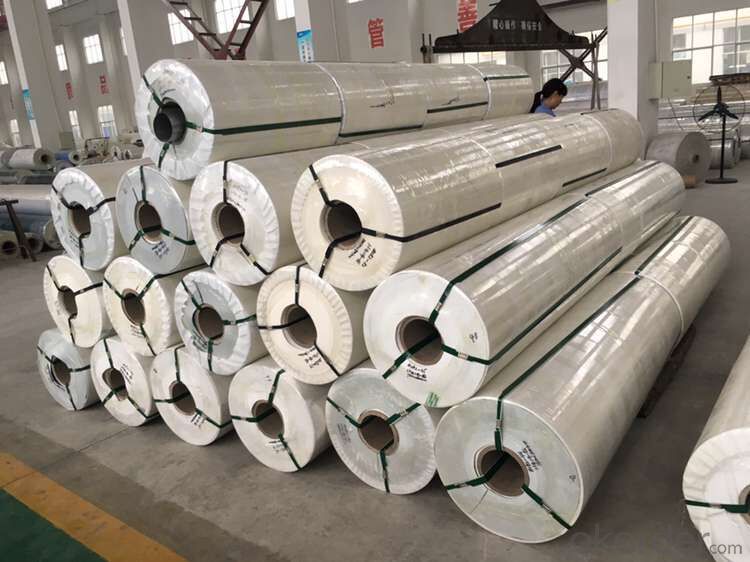

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green/White Thickness 2.0mm/3.0mm/4.0mm PVC Conveyor Belt

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

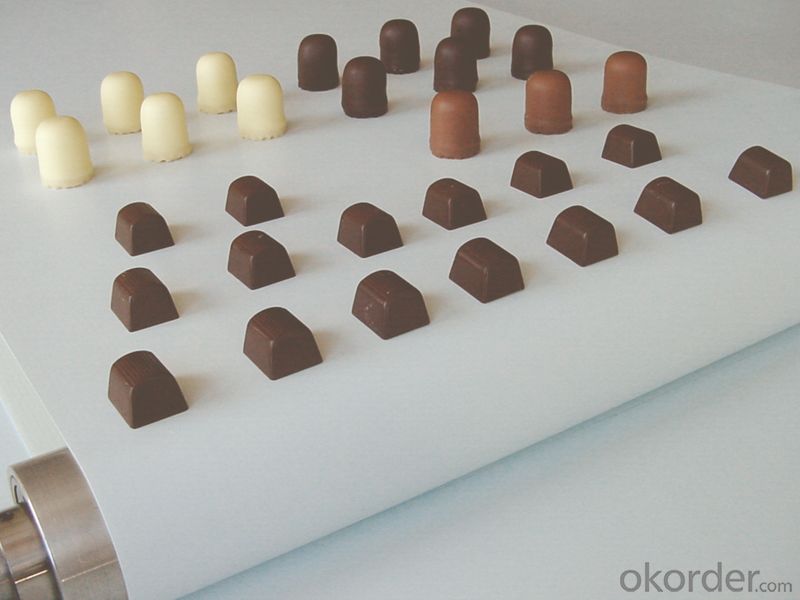

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

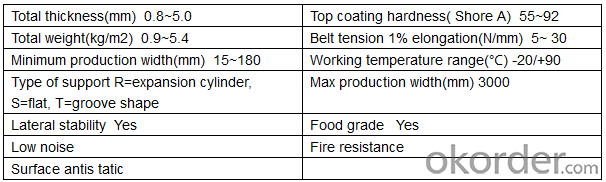

PVC Conveyor Belt Specification

Photos of Food PVC Conveyor Belt

FAQ

Can you give me discount?

Yes, of course. If you talk with us, you’ll get more.

Will you send me free sample?

Yeah, she'd love to; can you buy her a ticket?

Do you like to accept small orders?

We enjoy to grow up together with all our clients, whatever big or small.You will become bigger and bigger to be with us.

Buyer attention

If you are interested in our products and company, please leave a message here or E-mail to us, We will reply you without any delay.

- Q:Can olive nets be used for olive tree wind protection?

- Yes, olive nets can be used for olive tree wind protection. Olive nets are typically used to cover the olive trees and protect them from various external factors such as winds, pests, and birds. They provide a physical barrier that can reduce the impact of strong winds on the olive trees, preventing damage to the branches, leaves, or fruit. Additionally, these nets can also help in maintaining a stable microclimate around the trees, reducing the chances of water loss and maintaining optimum growing conditions.

- Q:Do olive nets protect against olive tree sunburn damage?

- No, olive nets do not protect against olive tree sunburn damage. Olive nets are primarily used to prevent birds from accessing and damaging the olives. To protect against sunburn damage, other methods like proper pruning, providing shade, and applying a protective coating to the tree trunk are recommended.

- Q:Are olive nets resistant to UV radiation?

- Yes, olive nets are typically designed to be resistant to UV radiation.

- Q:How do you secure an olive net to the ground?

- To secure an olive net to the ground, you can use various methods such as using ground stakes or pegs, tying the net to heavy objects like rocks or bricks, or burying the edges of the net in the soil. These methods help ensure that the olive net remains taut and secure, preventing any unwanted movement or access to the olives.

- Q:Can olive nets be used in olive groves with limited access to electricity?

- Yes, olive nets can be used in olive groves with limited access to electricity. Olive nets are primarily used for collecting olives during harvesting season and do not require electricity for their basic function. However, if electricity is needed for ancillary processes such as mechanized shaking or sorting, alternative power sources like generators or manual labor can be employed in groves with limited access to electricity.

- Q:Can olive nets be used in regions with limited access to water resources?

- Yes, olive nets can be used in regions with limited access to water resources. Olive trees are drought-tolerant and require less water compared to other crops. By using olive nets, which help collect olives efficiently during harvesting, farmers can conserve water by reducing the need for irrigation. Additionally, olive trees have deep root systems that allow them to access underground water sources, making them suitable for regions with limited water availability.

- Q:Can olive nets be used in different weather conditions?

- Yes, olive nets can be used in different weather conditions. They are designed to withstand varying weather conditions, including rain, wind, and sunlight. They provide protection to olive trees from extreme weather elements, such as hailstorms or heavy winds, and also help to regulate temperature and humidity levels.

- Q:Can olive nets be used in areas with saltwater exposure?

- Yes, olive nets can be used in areas with saltwater exposure. These nets are typically made from durable materials that are resistant to corrosion and degradation caused by saltwater. They can effectively protect olive trees from birds and other pests, even in coastal regions.

- Q:Do olive nets require any special storage conditions?

- Yes, olive nets require special storage conditions to maintain their effectiveness and longevity. They should be stored in a cool, dry place away from direct sunlight to prevent damage from UV rays. Additionally, it is crucial to keep them away from any sharp objects or chemicals that could potentially cause tears or deterioration. Proper storage will help preserve the quality and lifespan of olive nets.

- Q:What is the role of calcium carbonate in plastics?

- Improving the dimensional stability of plastic productsThe addition of calcium carbonate plays a skeleton role in plastic products, and has a great effect on the stability of plastic product size.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Green/White Thickness 2.0mm/3.0mm/4.0mm PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords