Green Smooth Gloss Matt PVC/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green Smooth Gloss Matt PVC/PU Conveyor Belt

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

PVC/PU conveyor belt/FDA

1. material: PVC/PU

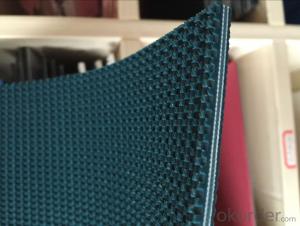

2. color: white,dark green,sky bule,etc

3. surface: smooth,matt

4. thickness:2mm/2.5mm/3mm/as request

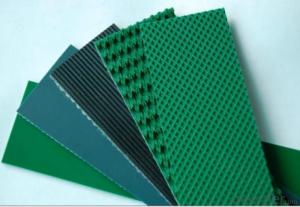

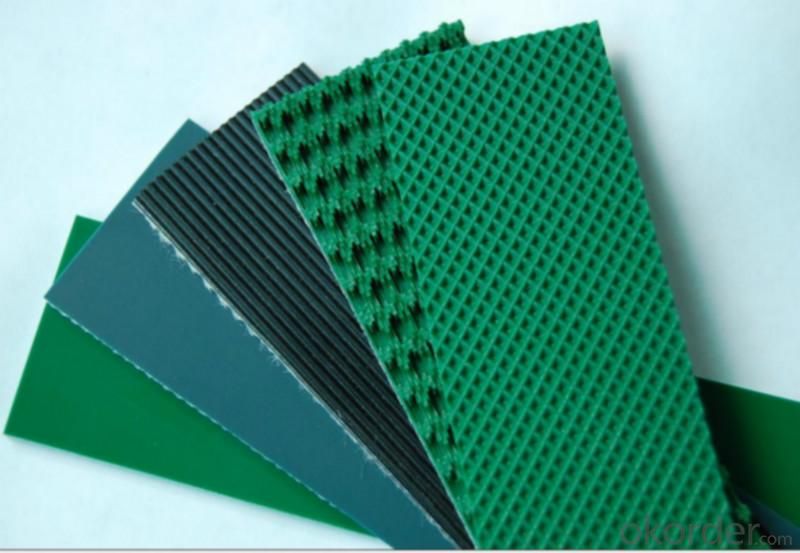

PVC conveyor belt

No. of fabric plies:1, 2, 3, 4 ,5ply.

Surface:smooth,matt,diamond,rough,etc.

thickness:1mm-8mm

Features:

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

Product Photos

For more informations,please contact us freely,thank you.

- Q:Do olive nets protect against olive tree pests other than olive fruit flies?

- Yes, olive nets can provide protection against various olive tree pests other than olive fruit flies. These nets act as a physical barrier, preventing pests like moths, birds, rodents, and insects from accessing the olive fruits and damaging the tree. Additionally, olive nets also offer protection against adverse weather conditions and reduce the risk of fungal diseases.

- Q:Can olive nets be customized for specific grove sizes?

- Yes, olive nets can be customized for specific grove sizes. Olive nets can be tailored to fit the dimensions and requirements of different grove sizes, ensuring effective coverage and protection for the olive trees.

- Q:Do olive nets require any special installation techniques for espaliered trees?

- Yes, olive nets do require special installation techniques for espaliered trees. The nets need to be carefully placed and secured to prevent damage to the trees and ensure proper support for the fruit-laden branches. Additionally, it is important to consider the growth patterns of the trees and adjust the installation accordingly to allow for optimal air circulation and sunlight exposure.

- Q:Are olive nets suitable for olive tree propagation from cuttings?

- No, olive nets are not suitable for olive tree propagation from cuttings. Olive nets are typically used for harvesting olives by catching the ripe fruits that fall from the trees. To propagate olive trees from cuttings, it is best to use specific propagation techniques such as rooting hormone treatments, proper soil mixtures, and controlled environments to encourage successful rooting and growth of the cuttings.

- Q:Are there any specific techniques for removing olive nets after harvesting?

- Yes, there are specific techniques for removing olive nets after harvesting. One common method is to carefully lift the nets from one end, allowing the olives to roll off into a collection container or onto a tarp. Another approach is to gently shake the nets to dislodge the olives, ensuring they fall onto a clean surface. Additionally, some farmers use mechanical devices or tools designed specifically for removing olives from the nets. It is important to handle the nets with care to minimize damage and preserve their longevity for future use.

- Q:Are olive nets effective in preventing olive fruit fly infestation?

- Yes, olive nets are effective in preventing olive fruit fly infestation. These nets act as a physical barrier, preventing the flies from accessing the olive fruits and laying their eggs. By blocking their entry, olive nets significantly reduce the infestation rate and help in maintaining a healthy olive crop.

- Q:How does an olive net affect the harvesting efficiency?

- An olive net significantly improves harvesting efficiency by effectively capturing olives as they fall from the tree, reducing the time and effort required for manual collection.

- Q:Can olive nets be used on olive trees grown in coastal regions?

- Yes, olive nets can be used on olive trees grown in coastal regions. Olive nets are commonly used for various purposes, including protecting olive trees from birds, reducing fruit drop, and facilitating harvesting. Since coastal regions often have a higher bird population, using olive nets can help prevent bird damage to the olive trees and fruits. Additionally, the nets can also provide some protection against strong coastal winds, which can potentially cause damage to the trees. Therefore, using olive nets is beneficial for olive trees grown in coastal regions.

- Q:Are there any specific colors of olive nets that are more effective?

- There is no specific color of olive nets that is proven to be more effective. The effectiveness of olive nets depends more on their design, material quality, and proper installation rather than their color.

- Q:The working principle of plastic mould

- The moving die part is mounted on the moving template of the injection machine, and can be moved with the mould system on the injection machine during the injection molding process. Start injection molding, mold closing system drives the movable die toward the fixed mold direction, and at the parting surface and the fixed mold of I, the accuracy of the mold oriented mechanism, a guide column and a guide column is opened holes in the fixed template guarantee. The movable mould and the fixed mould of after fixing groove in the template and fixed on the movable punch on the template structure and product shape and uniform size of closed cavity, the clamping force can be provided in the clamping system of injection molding process in the cavity of the lock, to avoid it to open up in the press under the force of the plastic melt. The injection from the nozzle in the plastic melt into the mold through the opening in the mainstream channel die central, then the sub channel and the goods to be poured into the mold cavity, the mold cavity is filled with melt and after packing, feeding and cooling, clamping system with moving die back reset, so that the dynamic model with two fixed mold opened from sub type surface. When the movable die back to a certain position, installed in the interior of the stripping mechanism will be in the clamping system in pushing device produced by the action of moving and die the other part, so the aggregate will products and runner and runner was the top of the runner off from their punch on one side of the driven mode in this, a complete injection molding process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Green Smooth Gloss Matt PVC/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords