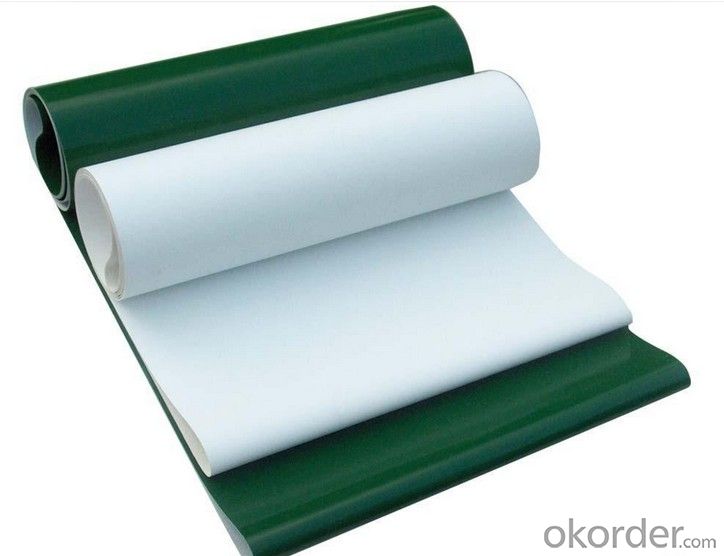

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

Descriptions of PVC Conveyor Belt

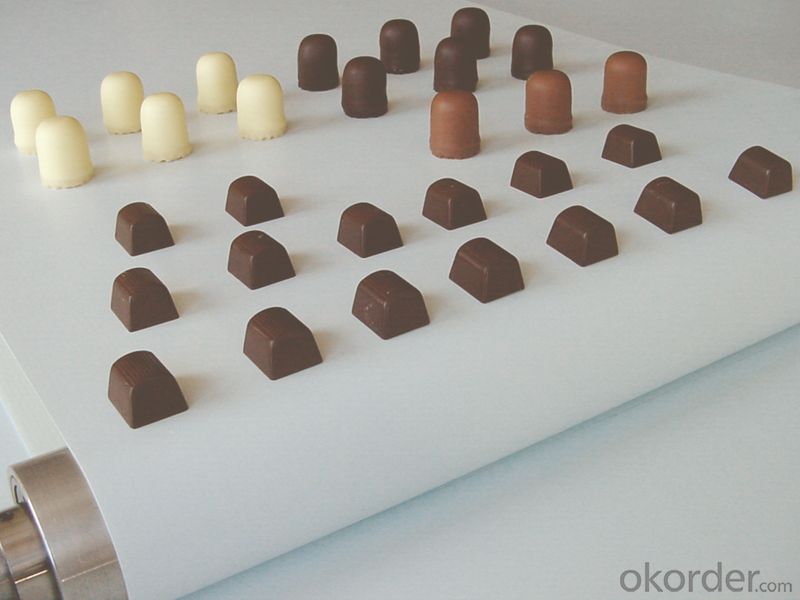

PVC conveyor belt for Conveyance and production assembly lines in the areas of food,beverage, cigarettes,tobacco,airportetc.

Thickness: 2.0mm

Width: Width of the largest production 3 meter

Length: According to the customer request production. Regular length is 100 meters.

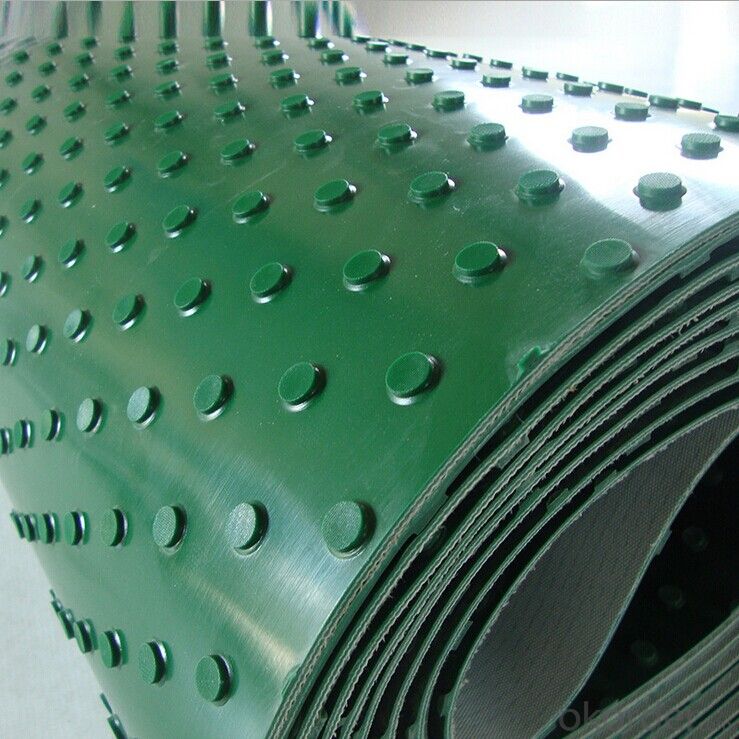

Color: White, green, black etc.

Can be produced as customers' requirements, such as thickness, width and length.

Features of PVC Conveyor Belt

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

It adopts high-intensity polyester filament and yarn weave as the whole core, and then is impregnated by the PVC&PU. We introduce the key technologies and equipment from the United Kingdom Specialization (Fenner) Corporation in the production.

Applications of PVC conveyor belt

Widely used in the Conveyance and production assembly lines in the areas of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre , electronics, pharmaceutical, printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q:What is the rubber composition and function of the airplane tyres?

- Polybutadiene rubber is prepared by the solution polymerization of butadiene butadiene rubber, with excellent cold resistance, abrasion resistance and flexibility, but also has good anti-aging properties. Polybutadiene rubber is mostly used in the production of tires, a small part for manufacturing cold products, cushioning materials and belt and rubber shoes. Butadiene rubber drawback is the tear resistance of the cross, wet skid resistance is not good. Isoprene rubber is the abbreviation of polyisoprene rubber. It is produced by solution polymerization. Isoprene rubber, like natural rubber, has good elasticity and wear resistance, excellent heat resistance and good chemical stability. Isoprene rubber (not before processing) strength was significantly lower than that of natural rubber, but the quality uniformity, processing performance is better than natural rubber. Isoprene rubber can be used instead of natural rubber to make heavy-duty and off-road tires, and can also be used to produce all kinds of rubber products.

- Q:How to test the abrasion resistance of rubber?

- As long as the amount of carbon black is added, the wear resistance will be increased. Have the Akron abrasion resistance test (the rubber disc shape small rubber wheels on the wheel rotating friction, turn a lap after the contrast test before and after the rubber wheel quality, poor quality of smaller, better resistance).

- Q:What is the relationship between the hardness and tensile strength of rubber pad?

- The molecular weight increases, increasing the fan Edward force, the chain segment is not easy to slip, the equivalent of molecules formed between physical crosslinking points with the molecular weight increased, the tensile strength increased to a certain extent reached equilibrium; the microstructure of the molecule, such as the effect of CIS and trans type structure; crystallization and orientation.

- Q:Classification of other rubber sheets of wear-resistant rubber plates

- RIT flat wear-resistant plywoodNon slip and relatively ordinary wear, usually used in less tension fabric, nylon belt, roller wrap, or ordinary environment of the drum wrapped plastic processing.RIT type wear resistant rubber plateThe surface of the rubber plate is of a rhombus shape, which has a strong anti slip and abrasion resistance. It is usually used in the fabric belt and middle and high strength steel belt and roller package processing. It is the most frequently used roller wrapped rubber sheet at present. Especially 10mm and 12mm thick rhombus rubber sheet.

- Q:How can the frictional properties of rubber improve?

- The viscoelastic parameter tan delta has a direct influence on the friction force, while the decrease of the rubber cross degree makes the tan delta increase. Therefore, the friction coefficient increases, and the friction coefficient and wear increase as well. From a physical and chemical point of view, the weaker the cross-linking, the higher the rate of wear is due to a lower degree of cross-linking which is easily caused by mechanical stress. It is found that the crosslinking degree of ethylene propylene three - element rubber increases with the irradiation of electron beam, which reduces the friction.

- Q:Rubber soaked with hot water will not come out harmful substances?

- Chloroprene rubber chloroprene as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength rubber, heat resistance and light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good

- Q:How to make white rubber products do not yellow or delay yellowing time?

- The process of yellowing resistance is very complicated and involves many aspects, but the prevention of a certain point is not up to standard.Yellow change is mainly formed by aging. Controlling yellowing is the process of controlling aging.

- Q:What are the causes of fracture in rubber products?

- Rubber products appear broken phenomenon, mainly for the following reasons:1, rubber products for a long time led to the phenomenon of fracture;2, too tired lead to rubber products broken;3, long-term exposure to ultraviolet light will cause rubber products broken;4, in the production of the use of chemical additives and materials conflict, resulting in incompatible and broken;5, the production process, the release of time is not appropriate, resulting in fracture (such as scratches);6, abrasive structure is irrational, lead to fracture;7, the use of materials is irrational, leading to fracture is also common;8, materials placed too long, in use, resulting in broken products, resulting in waste.

- Q:The silica gel of the kettle is the white one that is waterproof and leaked out

- Butadiene styrene rubber (SBR) copolymer of butadiene and styrene. Performance is close to natural rubber, is the largest yield of general-purpose synthetic rubber, characterized by wear resistance, aging resistance and heat resistance, more than natural rubber, texture is more natural rubber uniform. Disadvantages are: low elasticity, anti bending, anti tear performance is poor; the processing performance is poor, especially the poor, low strength self adhesive rubber. Temperature range: about 50 DEG C + 100. Mainly used instead of natural rubber to make tires, rubber sheets, hose, rubber shoes and other general products.

- Q:What advantage does ethylene propylene rubber with three yuan compare to two yuan ethylene propylene rubber?

- In recent years, the third monomer and new technology development, foreign developed 1 7- octadienoic, 6, 5, two 10- methyl -1, 9- eleven, 7- two three ene 3, methyl -1, 6- octadienoic, 5 7-, two methyl -1, 6- octadienoic, 7- methyl -1, 6- octadiene as the three EPDM third monomer, the performance of three Yuan rubber has been enhanced. The monomer and content of third monomer in three yuan ethylene propylene rubber have direct influence on vulcanization rate and vulcanizate property. Among them, dicyclopentadiene (DCPD) as the third monomer, although the price is low, but the three Yuan rubber vulcanization speed is slow, difficult and high degree of unsaturation diene rubber and use; to ethyiidenenorbomene (ENB), 6 10-, two methyl -1, 5, third monomer three Yuan rubber vulcanization speed 9- eleven three ene as fast, the former has become the main varieties of three yuan of ethylene propylene rubber. The third monomer content in iodine said three EPDM iodine value is generally 6-30, mostly around 15. The iodine value is 6-10, curing speed is slow, difficult and high unsaturated rubber; iodine value is 25-30, for ultra high speed curing type, available in any proportion and high unsaturated diene rubber and use. Therefore, three yuan ethylene propylene rubber and other rubber in use, should pay attention to choose the appropriate three yuan ethylene propylene rubber varieties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords