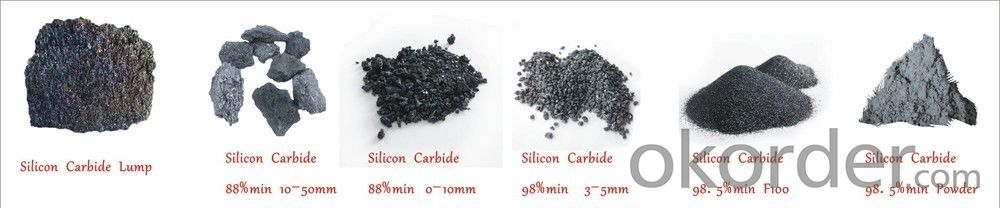

Green/Black SIC Silicon Carbide Made in China for Abrasive and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | CNBM | Model Number: | silicon carbide |

| Material: | SIC | Usage: | Polishing lapping refractory metallurgical | Abrasive Grain Sizes: | 12-3000# |

| Color: | Black and green | Name: | SIC | Application: | Polishing lapping refractory metallurgical |

| PAYMENT TERM: | T/T | Sample: | Provide | Package: | Jumbo Bag |

| Hardness: | 9.15 Mosh | Feature: | High Density | Quality: | Excellent |

Packaging & Delivery

| Packaging Details: | Silicon Carbide Powder:25kg bags loaded in 1 ton jumbo bags Silicon Carbide Lump: 1 ton loose in Jumbo bags. Or as customer request. |

| Delivery Detail: | 20 days after buyer's instruction |

Black Silicon Carbide is made by a precision water classification process and air flow classification using material that is produced from the reaction between high purity silica sand and petroleum coke in a resistance-type furnace. Measuring 9.0+ on the MOHS scale of hardness, silicon carbide is one of the hardest abrasives known in the industry. The inherent friability of the sharp crystalline structure assures the continuous exposure of new cutting edges, which produces a faster and cleaner cutting performance.

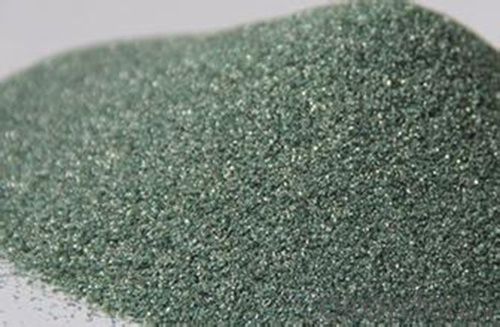

Green silicon carbide is produced as the same type as the black silicon carbide,except the different raw materials. It’s crystallization have higher purity and hardness.Green silicon carbide is suitable for processing hard alloy,metallic

and non-metallic material with hard and brittle feature such as copper, brass, aluminum,magnesium,jewel, optical glass, ceramics, etc. Super micro-power of it is also a kind of ceramics material.

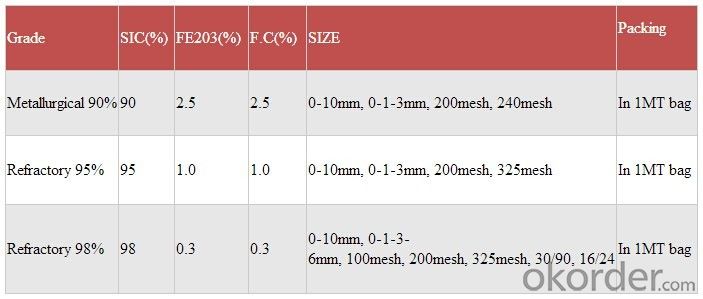

Chemical composition (%)

Grit size | SiC | F.C | Fe2O3 |

20# - 90# | ≥99.5 | <0.20< span=""> | ≤0.20 |

100# -180# | ≥98.5 | <0.25< span=""> | ≤0.50 |

220# - 240# | ≥97.5 | <0.25< span=""> | ≤0.70 |

F230 F360 | ≥97.5 | <0.30< span=""> | ≤0.70 |

F400 F600 | ≥95.5 | <0.30< span=""> | ≤0.70 |

F800 F1200 | ≥94.0 | <0.50< span=""> | ≤0.70 |

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:Why the refractories should be waterproof and wetproof

- The binding agent of many raw materials is water-soluble. It will be useless when meeting water.

- Q:What is the fireproofing requirements of external wall thermal insulation materials?

- External wall thermal insulation materials fire rating regulations, 1, the height of a building is greater than or equal to 100m , the combustion performance of insulation materials should be level A; 2, the height of a building is greater than or equal to 60m but less than 100m, the combustion performance of insulation materials should not be less than the level B2. When using level B2 thermal insulation material, every layer should set horizontal fire barrier zone 3,The height of building is be equal or greater than 24m but less than 60m, the combustion performance of thermal insulation material should not be less than the level B2. When using level B2 insulation material, each two-layer should set fire barrier zone ; 4, the height of building is less than 24m, the combustion performance of insulation materials should not be less than the level B2. Besides, when using level B2 thermal insulation material, each three-layer should set a horizontal fire barrier zone.

- Q:Can anyone say something about what A-level fire-proof decorative material is?

- Combustion performance rates of decoration materials ratess combustion performance of decoration materials A incombustible B1 flame retardancy B2 flammability B3 high flammability The B1 rate combustion performance of gypsum plaster board and mineral wool acoustic panel absorber installed on steel joist can be used as A-level decoration materials. Inorganic decorative coating applied on the A level substrate can be used as A level decoration materials. Hope you adopt

- Q:Who knows the roofing fireproofing and waterproof material?

- Colorful glass?fiber asphalt shingles the roofing through special materials treatment just like wearing a waterproof, fireproof coat, water rolling down from the roof is similar to the effect of lotus leaf drops, the wall will be always in the dry state, having excellent waterproof, mould proof, efflorescence and weathering. It can prevent the growth of moss and keep the surface clean. And let your roof does not change color for a long time. Colorful fiberglass asphalt shingles materials are widely used in: All types of buildings roofing waterproofing, leak, fire, pollution, wind, and mould proof and moisture-proof of libraries and archives. The color retention of ancient architecture and protection of human cultural relics. Through the number of ten million square meters of engineering applications and two decades of practical test, it welcomed by users.

- Q:What are grade classifications of the external walls for fireproofing?

- The basic level can be divided into: A1, A2, B1, B2, B3 and other levels. There are many technical indicators to make specific division, but I partly cannot report for a while, because it is very professional and technical. Please contact Qingdao Shanfang Instrument Co., LTD for details, they specialized in the external wall thermal insulation materials fire?rating testers.

- Q:What are the differences and connections between softening temperature of the refractory under a fixed load and thermal resistant creep property of the refractory?

- The result of refractoriness under load is temperature while the result of creep is percentage of deformation. Refractoriness under load and creep can be tested by an instrument. Refractoriness under load reflects the temperature in which the deformation reaches a certain degree under the condition of load. Creep reflects the deformation refractory has under the condition of constant temperature and load. Both refractoriness under load and creep are important criterion for the operating temperature of refractory.

- Q:How can refractory materials be divided?

- Refractory materials in China can be roughly divided into refractory products and unshaped refractories.

- Q:What's the fireproof specification for constrcution external wall thermal insulation materials?

- Specification for constrcution external wall thermal insulation materials: Article 1 In order to implement the "State Council opinions on strengthening and improving fire prevention work" (state issued [2011] No. 46), to standardize fireproof design and application of external wall thermal insulation materials of newly constructed, renovated, and expanded civil buildings and to prevent and reduce fire of building external wall thermal insulation materials, this provision is made in accordance with relevant national technical standards and our province real situation. Article 2 When there is no cavity between external wall thermal insulation material for exterior wall and base wall and between decorative layers, the insulation system shall comply with the following provisions: (A) Residential buildings: 1. When the building is higher than 54m, combustion performance of the thermal insulation material shall be A level; 2. When the building is not higher than 54m,combustion performance of the thermal insulation material shall be at least B level. When using B1 level insulation materials, non-combustible materials should be used to make the protective layer, and a protective layer thickness of the first floor of the building should be not less than 10mm, the other floors not less than 5mm; incombustible?materials of more than 300mm height should be used to make horizontal fire barrier zone in every floor. (B) Other buildings in addition to residential buildings

- Q:What dose the fireproof and thermal insulation material include?

- Protective cloth, fireproof cloth, plastic coated cloth, PVC tarpaulin, flame retardant cloth, duct cloth, automobile tarpaulin, PVC protective cloth, the freight yard covered cloth, PVC plastic coated cloth, Industrial Canvas, widely used in automobile tarpaulin, trains covered cloth, ships covered cloth, open-air yard covered cloth, industrial and agricultural covered cloth ; used in glass, timber, fertilizer plants, steel plants, mechanical hardware factories, feed mills, grain storages, container plants, oil refineries plants, packaging plants, paper plants, air conditioning plants, logistics, ore factories, fleet, rail and sea fields, etc.

- Q:Does anyone know the characteristics of refractory for glass kiln?

- Quartzitic sandstone. Also known as quartzitic sandstone or white gravel. Which is a kind of natural refractory and quartz sandstone bonded by the kaolinite. Who appearance is better to be steel-grey, dense and hard, free of impurities and stripes. Its main crystalline phase is mainly quartz and kaolinite. Which has obvious stratified structure and anisotropism. The refractoriness fluctuation is between 1650~1730 ℃. The expansibility of quartzitic sandstone is different from that of silica?brick, who has maximum coefficient of thermal expansion under temperatures of 700 ~ 800 ℃, and it is most likely to burst at this time. The load softening temperature and the compression strength of calcined quartzitic sandstone have been improved significantly, with small residual expansion, stable volume, better thermal shock resistance, so it is generally to use calcinated quartzitic sandstone as refractories. which has been widely used as sidewall blocks on the small and medium sized furnaces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Green/Black SIC Silicon Carbide Made in China for Abrasive and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords