GRE PIPE ( Glass Reinforced Epoxy pipe)for IMO L3 Fire Resistence

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 200000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GRE Pipe Description

GRE pipe is short for Glass Reinforced Epoxy pipe.

Generally high pressure FRP pipe, mainly used in oil field oil, water, polymer injection pipelines, natural gas transportation, urban drainage, drinking water pipelines, chemical industry, brine pipeline, fire pipelines and other fields.

Main Application:

1. Pipeline of brine, water and crude oil

2. Pipeline of polymer solution

3. Collection pipeline of crude oil and natural gas

4. Oilfield sewage, chemical sewage and waste water disposal pipe

5. Water distribution system

6. Petrochemical technical pipeline

Main Features of the GRE Pipe

1. High physical-mechanical character

2. High corrosion-resistant capability

3. Excellent heat-Rsistant capability; the mormal working temperature is 80 degree, which can meet the requirement of technology of oil extraction and effusion.

4. High-pressure-resistant capability: normal operating pressure grade from 3.5MPa to 25MPa.

5. Light weight

6. Long life, the designed service life is not shorter than 20 years.

7. High flow property of medium, non scaling, non depositing wax, will not being clogged.

8. Screw threaded connections and convenient installation.

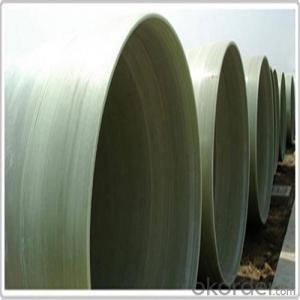

GRE Pipe Images

GRE Pipe Specification

1.Diameter:1.5inches(38mm)--24inches(600mm)

2.Pressure Grade:3.5---25MPa

3. Production Length: 9m or 11.8m

4. Connection Methods: API screw thread seal with aquaseal connection of eight rounds or ten rounds

FAQ of GRE Pipe

Q: What are the basic characteristics of the glass tube

Excellent physical and mechanical properties

Density fiberglass pipe is usually 1.8-2.1g / cm3, about 1/4 of steel, are higher than that of steel, cast iron and plastic than strength. The weight of the glass tube is generally greater than the same size steel 1/3 superior physical and mechanical properties; in addition, the thermal expansion coefficient of the glass tube and steel roughly, only 0.5% of the thermal conductivity of steel, is a good thermal and electrical insulation material.

Q: Is GRE Pipe chemical resistant with a long life?

GRE pipe has a special resistance to chemical corrosion in pipes criss-cross, dotted down environment, you can choose a different corrosion-resistant pipes according to the requirements of the medium.

Q: How are the hydraulic properties?

Water is one of the important mechanical properties of glass pipe. Hydraulic fluid excellent characteristics mean little head loss, you can use a smaller diameter or smaller power pump, thereby reducing the initial investment pipeline projects, save energy, reduce operating costs.

- Q:Which is better, pultruded FRP square pipe with PVC?

- Wear-resistant pipeline transportation has been in the power, metallurgy, coal, petroleum, chemical, building materials, machinery and other industries, and high-speed development.

- Q:Mending method for glass fiber reinforced plastic pipe

- The method for mending and mending the glass fiber reinforced plastic pipe is hand paste, and the repairing steps are as follows:The stones must be taken away so that the pipes are restored to their original shape.Into the pipe, grinding first and lining the lining. If you can't get into the pipe, polish it from the outside, polish it to the lining, and then make a new lining.Reinforce the structure with a cloth.

- Q:What is the compressive strength of all kinds of FRP materials?

- Anti fouling and anti moth: unsaturated polyester resin surface clean and smooth, will not be ocean or sewage in the shellfish, fungi and other microorganisms stained, moth, so as to increase roughness, reduce water cross section, increase maintenance costs. FRP pipes are free from these pollution and are clean for a long time. At the same time, because of its smooth inner wall and excellent corrosion resistance, it will not cause scale and microbial growth, effectively guarantee water quality and maintain the stability of water resistance. But the traditional pipe still exist after water resistance increases and the surface fouling phenomenon.

- Q:Which is better, PVC pipe and GRP pipe?!

- Of course, FRP pipe, high strength, aging resistance, PVC too crisp

- Q:What is the stiffness of FRP pipe?

- The ring stiffness is the comprehensive parameter of the tube's resistance to external pressure. Obviously, the choice of ring stiffness is one of the keys to ensure the safe operation of plastic underground drainage pipe under the external compressive load. If the ring stiffness of the tube is too small, the tube may undergo excessive deformation or buckling failure. On the other hand, if the ring stiffness is chosen too high, the excessive cross section moment of inertia must be used, which will result in too much material and too high cost.

- Q:What are FRP pipes made of?

- The wall of the pipe is smoothReduce flow resistance, increase flow speed and reduce energy consumption. Compared with the same size steel pipe, the flow rate of the same volume can be increased by about 10%, and no fouling and long-term use can not reduce the flow rate. The protection of cables in interference and heavy corrosion environment is better.

- Q:Are FRP pipes still developing?

- Glass steel complex (or perhaps not, but not absolutely continuous production mishap) manufacturing process, and China quality is not strictly controlled, low cost of pipeline as well as PVC and other engineering plastics, the high demand of the field of steel as reliable, is now used for chemical terminal treatment, city drainage etc..

- Q:Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- The use of a fixed fare set without further consideration to duct losses has been included in the quota project

- Q:What qualifications do FRP pipes need to export to Australia?

- We often have glass steel pipe or other products, have not heard what the other party needs special qualifications, as long as the customers are willing to order your goods, general foreign customers before shipment is to inspection, acceptance, what qualifications do not need. The key is whether domestic related requirements are met. Besides, you can ask the customer directly

- Q:Characteristics of FRP pipes

- (1) corrosion resistance: chemically inert material, excellent corrosion resistance, and can choose different corrosion resistant pipes according to the transmission medium.(2) strong mechanical strength: good water pressure resistance, good resistance to external pressure and impact strength, and piping and fittings can be designed according to the required pressure.(3) temperature adaptability: the use of temperature range: greater than -70 degrees Celsius, less than 250 degrees Celsius, under the freezing medium, the pipe is not split.(4) the resistance of the fluid is small: the pipe wall is smooth, the roughness coefficient is 0.0084, and the pipe diameter can be reduced under the same flow rate.(5) light weight, long life: light quality, convenient transportation, low construction cost, no maintenance, and the service life of more than 50 years.(6) maintain the water quality: non-toxic, conveying drinking water, can maintain long-term water quality sanitation. The application of FRP: the drinking water distribution pipe and line pipe conveying

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GRE PIPE ( Glass Reinforced Epoxy pipe)for IMO L3 Fire Resistence

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 200000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords