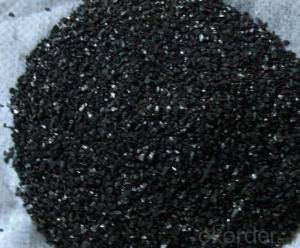

graphite powder for refractory brick,casting coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Provide various packing options according to customer requirements. |

| Delivery Detail: | 10-60 days according to order |

Products Picture

Specifications

1.Fixed Carbon 94%-99%

2.50, 80,100, 120,150,200,325 mesh

3.High purity flakes graphite

4.24 years experience

Natural Flakes Graphite Series

Advantage:

Perfect crystallization, great size in flake, high density, low content of mica, high luminance, excellent physical properties, such as resistance to high temperature, electric and thermal conductivity, self lubricity, and superior chemical stability

Size:

Adjustable to meet customer requirements, and major sizes include 50, 80,100, 120,150,200,325 mesh

Packing:

Provide various packing options according to customer requirements. Including Woven Bags, Paper Bags and Plastic Bags of 25KG, 50 KG, and 1000KG.

Application

Machinery

Metallurgy

Chemical industry

Light industry

Defense

Electronics

Batteries

Culture

Refractory material industries

ITEM | F.C %(min) | V.M %(max) | ASH %(max) | MOISTURE %(max) | SIZE |

-198 | 98 | 1.0 | 1.0 | 0.5 | -100mesh |

+198 | 98 | 1.0 | 1.0 | 0.5 | +100mesh |

-197 | 97 | 1.2 | 1.8 | 0.5 | -100mesh |

+197 | 97 | 1.2 | 1.8 | 0.5 | +100mesh |

-196 | 96 | 1.2 | 2.8 | 0.5 | -100mesh |

+196 | 96 | 1.2 | 2.8 | 0.5 | +100mesh |

-195 | 95 | 1.2 | 3.8 | 0.5 | -100mesh |

+195 | 95 | 1.2 | 3.8 | 0.5 | +100mesh |

-194 | 94 | 1.2 | 4.8 | 0.5 | -100mesh |

+194 | 94 | 1.2 | 4.8 | 0.5 | +100mesh |

-193 | 93 | 1.5 | 5.5 | 0.5 | -100mesh |

+193 | 93 | 1.5 | 5.5 | 0.5 | +100mesh |

-192 | 92 | 1.5 | 6.5 | 0.5 | -100mesh |

+192 | 92 | 1.5 | 6.5 | 0.5 | +100mesh |

-190 | 90 | 2.0 | 8.0 | 0.5 | -100mesh |

+190 | 90 | 2.0 | 8.0 | 0.5 | +100mesh |

-185 | 85 | 2.5 | 12.5 | 0.5 | -100mesh |

+185 | 85 | 2.5 | 12.5 | 0.5 | +100mesh |

-180 | 80 | 3.0 | 17.0 | 1 | -100mesh |

+180 | 80 | 3.0 | 17.0 | 1 | +100mesh |

+897 | 97 | 1.2 | 1.8 | 0.5 | +80mesh |

+896 | 96 | 1.2 | 2.8 | 0.5 | +80mesh |

+895 | 95 | 1.2 | 3.8 | 0.5 | +80mesh |

+894 | 94 | 1.2 | 4.8 | 0.5 | +80mesh |

+892 | 92 | 1.5 | 6.5 | 0.5 | +80mesh |

+890 | 90 | 2.0 | 8.0 | 0.5 | +80mesh

|

- Q:Please explain the use of coal in various aspects!

- The use of coal is very extensive, according to the purpose of its use for two main purposes: (1) power coal, (2) coking coal.

- Q:We want to barbecue, but will not give birth to charcoal, tossing more than an hour did not point, please help my brother and sister, thank you ~!

- Set a small charcoal on the third floor, the flame from the carbon hole out.With the fan at the bottom of the fan, accelerate the burning of charcoal, charcoal will ignite after a few minutes.

- Q:Activated carbon can be reused?

- Must be in the outdoor exposure (such as the balcony), because the gas to spit out to the outdoor;Can not be exposed after the rain, because the moisture will enter the body;When exposed to the ground must be paved with plastic sheeting to prevent moisture on the ground effect of exposure.

- Q:How to use long carbon printing effect

- Different skin, usage is differentIf the face is dirty, blackPut it on the face, a thin layer of good

- Q:Activated carbon is what? What use does it have?

- Using this principle, we can quickly and effectively remove harmful substances in the air, odor, etc., so that the air can be a direct and rapid improvement. Like activated carbon is very good, can effectively remove formaldehyde and other harmful gases.

- Q:The standard Meizhi is what mean?

- Standard coal, also known as coal equivalent, has a uniform calorific value. China's per kilogram of standard coal calorific value of 7 million cards. The different varieties and different contents of energy are converted into standard coal with a calorific value of 7 million calories per kilogram according to their different heat values.Energy standard coal coefficient = the actual calorific value of some energy (kcal / kg) /7000 (kcal / kg)

- Q:Coal can be used to do

- The use of coal is very extensive, according to the purpose of its use for two main purposes: (1) power coal, (2) coking coalThe main use of power coal in china:1 power generation coal: more than 1/3 of China's coal used to generate electricity, the current generation of the average coal consumption of standard coal 370g/ (kW * h) or so. The power plant using the calorific value of coal, the heat energy into electricity

- Q:What are the uses of coal?

- 3) coal for building materials: accounting for more than l0% of the power coal, the largest amount of coal used in cement, followed by glass, brick, tile, etc..4 general industrial boiler coal: in addition to the thermal power plant and large heating boiler, the general enterprise and the heating of the industrial boiler model, large quantity and scattered, coal accounts for about 30% of the coal.

- Q:Airlines are able what? Where do you need it? How much price ah? (unit price)

- Imported coal is now about 6500/ tons of domestic aviation coal price of 5500/ tons

- Q:How to deal with the absorption of formaldehyde? Want to reuse

- It is best to use active products, such as air purifiers, as well as some formaldehyde scavenger, etc.. Leadman environment decoration formaldehyde nemesis; Ba Jin, furniture smell scavenger, air purification machine can help you to solve the trouble of decoration pollution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

graphite powder for refractory brick,casting coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords