Graphite Electrode with Nipple with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to

700mm. Our products own the following characteristics: low electric resistance, good electric and

thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

Product Applications:

It is used for the electric arc furnace steel making. (About 70-80% graphite electrode is used for steel making).

It is used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow

phosphorus,matte, calcium carbide and so on.

It is used for the resistance furnace, such as the graphite making, melting glass, silicon carbide

making and so on.

Product Advantages:

28 drums counter-flow calcining furnace

Auto-control dosing system

Germany Enrich kneading system

3500MT vertical tamping&horizontal extruding press

Auto-comtrol ring backing furnace

Germany Feist-incon 2nd Baking Kiln

High pressure imprgnation system

Acheson high power DC graphitizing furnace

Japan Nachi NC electrode machining line

America lngersoll NC electrode machine line

Japan Nachi NC nipple machining line

Carbon fiber production line

Main Product Features:

Good electrical conductivity

High resistance to thermal shock

High mechanical strength

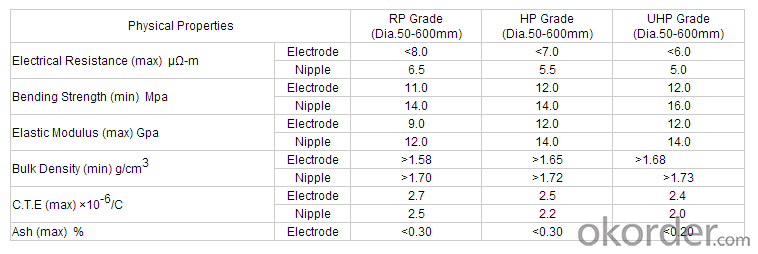

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

6. What standards do we have?

Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.

The third party testing is all available for us.

Product Picture

- Q:What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- The hardfacing of wear-resistant alloy powder block is mostly made by carbon arc surfacing. General selection of graphite or carbon arc surfacing carbon rod and plate electrodes, which has good conductivity, high melting point;

- Q:Can Naiduo high temperature graphite

- The reinforced graphite gasket is made of flexible graphite tape or flexible graphite and is molded into ring products of different sizes. Suitable for hot water, high temperature, high pressure steam, heat exchange liquid, nitrogen gas, organic solvent, hydrocarbon, low temperature liquid and other medium. Used in compressors, machines, pumps, valves, chemical instruments, instruments, etc..

- Q:Why should the carbon brush for the trolley be made of graphite?

- What you said is the graphite electrode graphite, there may be a high pure graphite graphite conductive rate so high, strong, high density, the graphite is mostly used in motor vehicles, such as generators, and electric tools.

- Q:What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- In the electrochemical process, the electrode should not affect the reaction on the working electrode, so platinum and graphite are often chosen

- Q:Why graphite can be used as conductive material?

- Widely used as electrode, graphite, carbon brush, carbon nanotubes, mercury rectifier cathode, graphite gasket, telephone parts, TV tube coating and so on in the electrical industry. The most widely used in the smelting of graphite electrode, alloy steel, iron alloy, graphite electrode, the strong current through the melting zone, the arc electrode into the electric furnace, the electrical energy into heat, the temperature rises to around, so as to achieve the purpose of melting or reaction. In addition, in the electrolysis of metal, magnesium, aluminum and sodium, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace used for the production of rigid sand is also made of graphite electrode as the conducting material of the furnace head.

- Q:I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- The problem is this. I have done the test of electrolytic copper sulfate, and the anode produced the same phenomenon. Finally, the chemistry teacher told me that it was because the graphite was broken in the process of electrolysis

- Q:What is the composition of petroleum coke and what is its use?

- Mainly used for making carbon products, such as graphite electrodes, anode arc, steel, non-ferrous metals, with aluminum for use; silicon carbide products, such as grinding wheel, rubber, sandpaper; producing goods for the production of synthetic fiber, calcium carbide acetylene and other products; also can be used as fuel for fuel, but for grading impact for grinding superfine grinding, through the JZC-1250 device can be made of coke powder after combustion, using coke powder as fuel is mainly some glass factory, coal water slurry plant etc..

- Q:What's the use of carbon?

- Common power graphite electrode. Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q:Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- In electrolysis industry, using graphite anode plate as the anode has a history of more than 100 years, the metal anode is in recent decades, the research and application of metal anode in China late last century, only in 70s the technology related to the research and experiment of metal anode, anode on electrolysis industry, mainly through the silver (2%) (0.5%): low silver lead silver alloy, lead and silver tin antimony alloy, lead calcium alloy and lead silver alloy adding nucleating agents and several stages

- Q:Do electroplating experiments, graphite as an electrode, graphite how to pre process to ensure that the coating will not fall, resulting in increased color of the solution

- Use a tight filter cloth as an anode pack

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Graphite Electrode with Nipple with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords