Graphite Electrode with Nipple Price-HZ -400mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

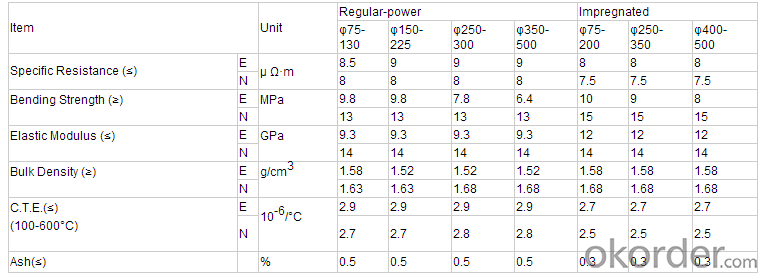

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:Will the brush grease not short-circuit the commutator?

- The reverse pole surface should be clean and dry. Any grease, moisture or dust will destroy the carbon film on the commutator surface. The carbon film can not be formed or destroyed. It is very harmful. Grease material will be embedded in the joint between commutator and commutator. Under the action of electric spark, it will be carbonized and conductive. When serious, it will cause partial short circuit between the reversing pieces and reduce the service life of reversing.

- Q:What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The graphite part is called pyrolytic graphite. Stronger than ordinary graphite, strong oxidation resistance.

- Q:What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- Because the carbon containing ash, a graphite resistor 2-3 times, so the use of graphite electrode is better.

- Q:Are graphite and carbon electrodes the same? What kinds of ore furnaces are used?

- The main components of carbon electrodes are graphite, carbon powder and other impurities which are not converted into graphite. The resistivity is higher than that of graphite electrode. These electrodes are mostly used in electric furnace steelmaking, smelting aluminium oxide and other electric arc furnaces.

- Q:Why graphite can be used as conductive material?

- Lubricants can not be used in high speed, high temperature, high pressure conditions, and graphite wear-resistant materials can be at the temperature and at a high sliding speed, without lubricating oil work. Many transporting corrosive media devices are widely used, which is made of graphite material piston ring, the sealing ring and the bearing, they are running, without adding lubricating oil, graphite and many metal processing when good lubricant.

- Q:Why is graphite a negative pole and copper is an anode?

- Graphite, as an electrode material, can conduct electricity, which belongs to an inert electrode. It only acts as a conductive agent, but does not participate in the electrolytic reaction process. So the anode is made, and copper is oxidized in the electrolysis of monovalent cations, so copper is used as the anode.

- Q:What is the composition of petroleum coke and what is its use?

- Petroleum coke can be used for the manufacture of graphite, smelting and chemical industries, depending on its quality. For example, the quality of cooked sweet coke coke, mainly used in the manufacture of ultra high power graphite electrode and some special carbon products; needle coke in steelmaking industry is an important material new technology development of EAF steelmaking.

- Q:Graphite electrode in milling machine processing, dust is especially big, boot 5 minutes, workshop can not open the figure, what is the solution?

- Because will cause a short circuit, the best selection of bag type dust collector, our company is graphite in Linzhou, and before you like, then Xinxiang Keli machinery to help us to design a set of dust removal equipment, and then the operation almost no dust, you can consult the specific

- Q:What are the losses in graphite electrode?

- So tell, this problem is to answer a lot, graphite under high temperature oxidation, generally around 400 degrees, began a slight oxidation, but the human eye is to be observed, with the increase of temperature, the graphite oxide will increase, this time should be used to protect gas or vacuum to protect what you said is, nitrogen protection, and general protection of nitrogen can reach more than 2000 degrees, if the high temperature to 3800 degrees, will you say that vapor formed in graphite surface. To achieve this temperature, it is necessary to add inert gas to achieve, otherwise, can not reach, generally to 4350 degrees, the graphite began to soften.

- Q:Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Can't。 During electrolysis, there is depletion of sulfite ions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Graphite Electrode with Nipple Price-HZ -400mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords