Grade SAE 4140 Steel Price Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Grade SAE 4140 Steel Price_Steel Round Bar

Details of Grade SAE 4140 Steel Price_Steel Round Bar

Name | Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

1.Size of 4140 Steel Round Bar | ||||||||

Round bar | Diameter(mm) | Length (mm) | ||||||

20~800 | 3000~9000 | |||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||

Max:800 | Max:2200 | Max:9000 | ||||||

The specification can be customized. | ||||||||

2.Chemical Compositons | ||||||||

Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

42CrMo | 0.38~0.45 | 0.17~0.37 | 0.50~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15-0.25 | ≤0.3 |

4140 | 0.40~0.45 | 0.15~0.35 | 0.75~1.0 | ≤0.035 | ≤0.040 | 0.8~1.1 | 0.15-0.25 | - |

SCM44 | 0.38~0.43 | 0.15~0.35 | 0.60~0.9 | ≤0.030 | ≤0.030 | 0.9~1.2 | 0.15-0.30 | ≤0.25 |

1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.9 | ≤0.025 | ≤0.035 | 0.9~1.2 | 0.15-0.30 |

|

3.Features of 4140 alloy steel | ||||||||

1. Chromium molybdenum alloy steel | ||||||||

2. Slightly higher carbon content then 4130 | ||||||||

3. Greater strength and heat treatment | ||||||||

4.Typical Applications | ||||||||

1. Applications in the oil and gas sector | ||||||||

2. Connection rods, collets, conveyor pins, | ||||||||

3. Gears, stem assemblies, | ||||||||

4. Pump shafts and tool holders | ||||||||

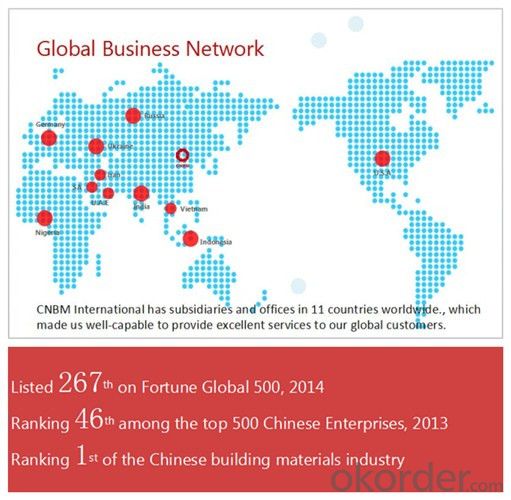

CNBM Introduction of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:What are the main characteristics of creep-resistant steel?

- Creep-resistant steel possesses high strength and resistance to deformation at elevated temperatures. It maintains its mechanical properties even under long-term exposure to high stress and high temperatures. Its ability to resist creep, or the gradual deformation under stress, makes it suitable for applications in power plants, boilers, and other high-temperature environments. Additionally, creep-resistant steel exhibits good resistance to corrosion and oxidation, ensuring its durability and longevity in harsh conditions.

- Q:What are the common challenges in machining titanium alloys?

- Successful and efficient results in machining titanium alloys require addressing several common challenges. One primary challenge is the inherent strength and hardness of the material. Titanium alloys are renowned for their excellent strength-to-weight ratio, making them ideal for various applications. However, this same strength makes them difficult to machine. The high strength of titanium alloys increases the cutting forces needed during machining, resulting in faster tool wear and reduced tool life. This necessitates the use of robust cutting tools made from carbide or ceramic, capable of withstanding demanding conditions and maintaining cutting performance. Another challenge in machining titanium alloys is their poor thermal conductivity. This characteristic leads to rapid heat buildup during cutting, causing localized high temperatures. These high temperatures can cause thermal damage to both the cutting tool and the workpiece, reducing dimensional accuracy and surface finish. To overcome this challenge, implementing effective cooling and lubrication techniques, such as using coolant or high-pressure air, is crucial to dissipate heat and prevent overheating. Furthermore, machining titanium alloys often results in the generation of built-up edge (BUE). BUE refers to the accumulation of workpiece material on the cutting tool, leading to poor chip evacuation, increased cutting forces, and surface finish issues. To mitigate BUE formation, it is recommended to use appropriate cutting speeds and feed rates, as well as cutting fluids that aid in chip evacuation and prevent material adhesion on the tool. Additionally, titanium alloys react strongly with oxygen, causing the formation of a stubborn oxide layer on the surface during machining. This oxide layer can cause tool chipping and premature wear. To combat this, it is necessary to employ suitable cutting speeds and feeds that efficiently remove material while minimizing prolonged exposure to the reactive nature of titanium alloys. Lastly, the low thermal expansion coefficient of titanium alloys can result in workpiece distortion and dimensional inaccuracies. To address this challenge, it is important to ensure proper fixturing and clamping techniques that minimize workpiece movement during machining. In conclusion, machining titanium alloys presents challenges such as high cutting forces, poor thermal conductivity, built-up edge formation, reactive oxide layer, and workpiece distortion. These challenges can be overcome by using appropriate cutting tools, effective cooling and lubrication techniques, proper cutting parameters, and careful workpiece handling.

- Q:What are the different types of bearing steel?

- There are several different types of bearing steel, including carbon steel, stainless steel, and chrome steel.

- Q:What are the different corrosion-resistant coatings for special steel?

- There are several corrosion-resistant coatings available for special steel, including zinc coatings, aluminum coatings, stainless steel coatings, and ceramic coatings. These coatings provide a protective barrier that prevents the steel from coming into contact with corrosive elements, thus extending its lifespan and maintaining its structural integrity.

- Q:What are the main applications of special steel in the automotive electrical systems?

- Special steel is commonly used in automotive electrical systems for various applications such as manufacturing electrical connectors, terminals, and wiring harnesses. It offers high conductivity, corrosion resistance, and superior strength, making it an ideal choice for components that require efficient flow of electrical current and durability in harsh environments. Additionally, special steel can also be utilized in the construction of sensors, relays, and other electronic devices within the automotive electrical system, ensuring reliable performance and longevity.

- Q:What are the properties of high-temperature tool steel?

- High-temperature tool steel possesses properties like exceptional hardness, wear resistance, and high temperature stability. It exhibits excellent strength and toughness at elevated temperatures, making it suitable for applications where tools are subjected to intense heat and stress. The steel retains its hardness and strength even at elevated temperatures, allowing it to maintain its cutting or shaping capabilities. Additionally, high-temperature tool steel has good dimensional stability, ensuring minimal deformation or warping under extreme heat conditions.

- Q:How does special steel contribute to the infrastructure development?

- Special steel contributes to infrastructure development in several ways. Firstly, its high strength and durability make it an ideal material for constructing buildings, bridges, and other critical infrastructure. Special steel can withstand heavy loads, extreme temperatures, and harsh weather conditions, ensuring the longevity and safety of these structures. Secondly, special steel is widely used in the manufacturing of machinery and equipment required for infrastructure development projects. From excavators and cranes to pipelines and power transmission systems, special steel provides the necessary strength, resistance to corrosion, and reliability needed for efficient and sustainable infrastructure development. Furthermore, special steel plays a crucial role in the transportation sector. It is utilized in the construction of railway tracks, road barriers, and vehicles, ensuring safe and reliable transportation networks. Special steel is also used in the energy sector for the production and distribution of electricity, as it is capable of withstanding high temperatures and pressure in power plants and transmission lines. In summary, special steel's strength, durability, and versatility make it an essential material for infrastructure development. Its contribution lies in the construction of robust structures, manufacturing of machinery and equipment, and the development of reliable transportation and energy systems, thereby facilitating the growth and progress of infrastructure worldwide.

- Q:How is nitrogen alloyed steel used in the production of high-strength bolts?

- Nitrogen alloyed steel is used in the production of high-strength bolts to enhance their mechanical properties. By adding nitrogen as an alloying element, the steel becomes stronger, more resistant to corrosion, and exhibits improved toughness. This makes the bolts suitable for applications requiring high levels of strength and durability, such as in construction, automotive, and aerospace industries.

- Q:What are the main applications of special steel in the packaging industry?

- Special steel has a wide range of applications in the packaging industry, primarily due to its exceptional strength, durability, and corrosion resistance. It is commonly used in the manufacturing of packaging machinery, such as conveyor systems, filling machines, and cutting tools, ensuring efficient and precise operations. Additionally, special steel is often employed in the production of packaging materials, including cans, containers, and closures, providing enhanced protection and preservation of goods.

- Q:How does special steel contribute to the machinery manufacturing industry?

- Special steel plays a crucial role in the machinery manufacturing industry by providing high-quality and durable materials for the production of various machine components. This type of steel is specifically engineered to possess exceptional strength, toughness, and resistance to wear, corrosion, and high temperatures. In the machinery manufacturing industry, special steel is utilized in the production of critical components such as gears, shafts, bearings, and cutting tools. These components are subjected to extreme mechanical forces, exposure to harsh environments, and repetitive motion, requiring a material that can withstand such conditions without compromising performance or safety. The exceptional properties of special steel enable machinery manufacturers to produce equipment that is reliable, efficient, and long-lasting. By utilizing this type of steel, manufacturers can enhance the overall performance and durability of their machinery, ensuring optimal functionality and minimizing the need for frequent repairs or replacements. Moreover, special steel allows for the design and production of more compact and lightweight machinery, leading to improved energy efficiency, reduced manufacturing costs, and increased productivity. The high strength-to-weight ratio of special steel enables the production of smaller and lighter components, without sacrificing durability or performance. Furthermore, the corrosion and heat resistance properties of special steel make it suitable for use in industries with demanding operating conditions, such as aerospace, automotive, and energy. It ensures that machinery can withstand extreme temperatures, chemical exposure, and abrasive environments, enhancing safety and reliability. In conclusion, special steel significantly contributes to the machinery manufacturing industry by providing materials with exceptional strength, toughness, and resistance to wear, corrosion, and high temperatures. Its utilization in critical components ensures the production of reliable, efficient, and durable machinery, leading to improved performance, reduced costs, and increased productivity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grade SAE 4140 Steel Price Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords