Grade AISI 304_316_321 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Grade AISI 304_316_321 Stainless Steel Round Bar in stock

Descriptio of Grade AISI 304_316_321 Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade AISI 304_316_321 Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

Company Information of Grade AISI 304_316_321 Steel Round Bar in Stock

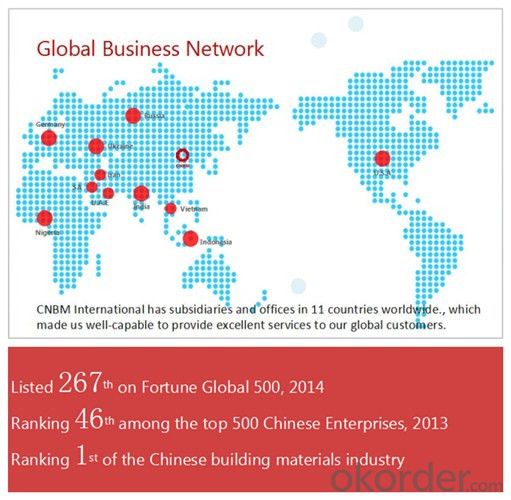

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade AISI 304_316_321 Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:How does special steel contribute to the chemical processing aftermarket industry?

- Special steel plays a crucial role in the chemical processing aftermarket industry by offering a wide range of benefits that enhance the overall efficiency and performance of chemical processing equipment. Firstly, special steel is renowned for its exceptional strength and durability, making it ideal for applications that involve high pressure, extreme temperatures, and corrosive environments. This durability ensures that the equipment can withstand the challenging conditions and operate reliably for extended periods, reducing the frequency of maintenance and replacement. Furthermore, special steel possesses excellent resistance to corrosion, oxidation, and chemical reactions, which are common challenges in the chemical processing industry. This resistance enables the equipment to handle a wide variety of chemicals without deteriorating or contaminating the process, thus ensuring the quality and safety of the end products. Additionally, special steel can withstand the formation of scale, deposits, and other contaminants that can hinder the efficiency of the equipment, thereby reducing the need for frequent cleaning and maintenance. Moreover, special steel offers superior mechanical properties such as toughness, hardness, and impact resistance, which are essential for handling and processing heavy loads and abrasive materials. This ensures that the equipment can withstand the demanding operational conditions and maintain its performance over time, resulting in enhanced productivity and reduced downtime. Another significant contribution of special steel to the chemical processing aftermarket industry is its versatility. It can be customized and tailored to meet specific requirements, allowing for the manufacturing of complex parts and components that are essential for various chemical processes. Special steel can be fabricated into different shapes and sizes, enabling the creation of intricate designs and structures that optimize the efficiency and effectiveness of the equipment. In conclusion, special steel is a vital component in the chemical processing aftermarket industry due to its exceptional strength, durability, resistance to corrosion and chemical reactions, as well as its versatility. By providing reliable and high-performance equipment, special steel contributes significantly to the overall efficiency, safety, and productivity of chemical processing operations.

- Q:How does special steel perform in high-temperature oxidation with sulfur-containing atmospheres?

- Special steel performs well in high-temperature oxidation with sulfur-containing atmospheres due to its enhanced resistance to sulfur-induced corrosion. The alloy composition and surface treatment of special steel enable it to form a protective oxide layer that prevents sulfur from penetrating the material, thereby reducing the risk of oxidation and corrosion.

- Q:How does special steel contribute to the manufacturing of turbine blades?

- Due to its unique properties and characteristics, special steel plays a critical role in the manufacturing of turbine blades. Turbine blades are exposed to extreme conditions, including high temperatures, high rotational speeds, and constant exposure to air and steam. To withstand these demanding operating conditions, materials must maintain their structural integrity and performance. Special steel, also known as superalloys, possesses exceptional mechanical properties, heat resistance, and corrosion resistance, making it an ideal choice for turbine blade manufacturing. Its high temperature resistance allows turbine blades to operate efficiently at elevated temperatures without significant deformation or failure. A key property of special steel is its ability to retain strength and hardness even at high temperatures. This is crucial for turbine blades, as they are constantly exposed to hot gases and steam in power generation applications. Special steel's resistance to creep ensures that turbine blades maintain their shape and structural integrity over time. Furthermore, special steel exhibits excellent corrosion resistance, protecting turbine blades from oxidation and other forms of degradation caused by the aggressive operating environment. This is particularly important in gas turbines, where the combustion process produces corrosive gases and particles that can damage the blades. Special steel's ability to resist oxidation and corrosion ensures the longevity and reliability of turbine blades. Moreover, special steel offers high strength-to-weight ratios, allowing for the design and manufacture of lightweight turbine blades. This lightweight characteristic improves aerodynamic performance and reduces energy consumption, as the blades require less force to rotate at high speeds. In conclusion, special steel significantly contributes to the manufacturing of turbine blades by providing exceptional mechanical properties, heat resistance, corrosion resistance, and lightweight characteristics. These properties ensure that turbine blades can withstand the extreme conditions of power generation applications, ultimately enhancing their performance, longevity, and overall efficiency.

- Q:What are the different surface coating techniques for special steel?

- Some of the different surface coating techniques for special steel include electroplating, hot-dip galvanizing, powder coating, thermal spraying, and chemical vapor deposition.

- Q:How does high-speed steel perform in high-temperature cutting operations?

- High-speed steel performs well in high-temperature cutting operations due to its exceptional heat resistance and ability to retain hardness at elevated temperatures. This enables it to maintain its cutting efficiency, withstand thermal stress, and resist deformation, resulting in improved tool life and productivity.

- Q:How does special steel perform under extreme cold conditions?

- Special steel is specifically designed to perform well under extreme cold conditions. It has excellent resistance to low temperatures and retains its strength and toughness even in freezing temperatures. This is achieved through the addition of alloying elements such as nickel, chromium, and molybdenum, which enhance the steel's ability to remain ductile and resist brittle fracture. In extreme cold temperatures, regular steel tends to become brittle and may fracture easily. However, special steel exhibits remarkable toughness and resilience. It can withstand the extremely low temperatures without losing its mechanical properties, making it suitable for various applications in cold environments. Moreover, special steel also offers excellent corrosion resistance, which is crucial when exposed to extreme cold conditions. Corrosion can be accelerated in cold environments due to factors like moisture, salt, and freezing and thawing cycles. However, the corrosion-resistant properties of special steel prevent it from deteriorating and maintain its structural integrity. Additionally, special steel has superb thermal conductivity, allowing it to efficiently transfer heat even in extremely low temperatures. This characteristic is essential in applications where heat transfer is critical, such as in cryogenic systems or cold storage facilities. Overall, special steel's exceptional performance under extreme cold conditions makes it an ideal material for various industries and applications, including aerospace, oil and gas, automotive, and construction. Its ability to maintain strength, toughness, corrosion resistance, and thermal conductivity at low temperatures ensures reliable and safe operation in severe cold environments.

- Q:What are the future trends in special steel manufacturing?

- Some of the future trends in special steel manufacturing include advancements in technology and automation, increased focus on sustainability and environmental impact, development of new alloys and materials with enhanced properties, and growing demand for specialized steels in industries like aerospace, automotive, and renewable energy. Additionally, there is a shift towards customization and tailored solutions to meet specific customer requirements, as well as an emphasis on research and development to drive innovation in the field.

- Q:What are the different surface modification techniques used for special steel?

- Some of the different surface modification techniques used for special steel include heat treatment, electroplating, coatings, and nitriding. These techniques are utilized to enhance the steel's hardness, corrosion resistance, wear resistance, and overall performance in various applications.

- Q:How does the corrosion resistance of special steel compare to regular steel?

- Generally, special steel outperforms regular steel in terms of corrosion resistance. Special steel is specifically engineered to possess enhanced resistance against corrosion, thanks to its unique composition and manufacturing process. It often contains higher levels of alloying elements like chromium, nickel, and molybdenum. These elements create a protective layer on the steel's surface, preventing it from reacting with corrosive substances. In contrast, regular steel tends to have lower corrosion resistance due to its composition and lack of alloying elements. It is more susceptible to rusting and other forms of corrosion when exposed to moisture, atmospheric gases, or chemicals. Additionally, special steels can undergo additional treatments such as heat treatment, passivation, or coating. These treatments further elevate their corrosion resistance by forming a barrier against corrosive agents. As a result, the lifespan and durability of the steel are extended in corrosive environments. To summarize, special steel surpasses regular steel in terms of corrosion resistance due to its composition, alloying elements, and additional treatments. This quality makes it the preferred choice in applications where corrosion resistance is crucial, such as marine environments, chemical processing plants, or infrastructure exposed to harsh weather conditions.

- Q:How long does special steel last compared to regular steel?

- Special steel generally lasts longer than regular steel due to its superior properties and enhanced durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grade AISI 304_316_321 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords