Grade 316 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Grade 316 Stainless Steel Round Bar in stock

Descriptio of Grade 316 Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade 316 Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

Company Information of Grade 316 Steel Round Bar in Stock

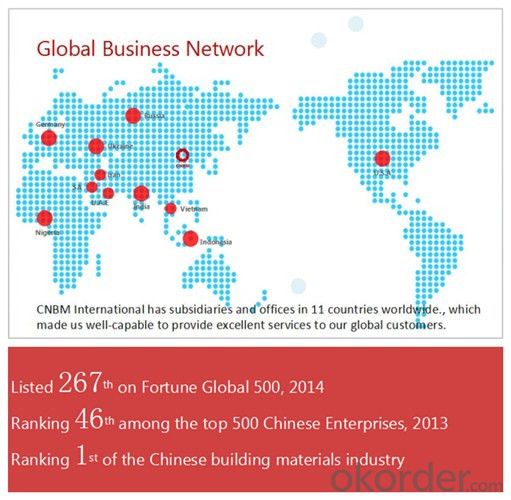

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade 316 Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:How is ultra-high-strength steel used in the construction industry?

- Ultra-high-strength steel is commonly used in the construction industry to enhance the structural integrity and resilience of buildings and infrastructure. Its exceptional strength-to-weight ratio allows for the creation of lighter and more durable structures. This steel variant is often employed in applications such as high-rise buildings, bridges, and offshore structures, where its superior strength properties provide increased safety and load-bearing capacity.

- Q:What are the requirements for special steel used in telecommunications infrastructure?

- The requirements for special steel used in telecommunications infrastructure include: 1. High strength: Special steel used in telecommunications infrastructure should have high tensile strength to withstand the heavy loads and stresses imposed on the structures. This ensures that the infrastructure remains stable and secure. 2. Corrosion resistance: As telecommunications infrastructure may be exposed to various environmental conditions, including moisture and chemicals, it is crucial for the special steel to have excellent corrosion resistance. This helps to protect the infrastructure from rust and deterioration, extending its lifespan. 3. Good weldability: Special steel used in telecommunications infrastructure should have good weldability to facilitate the construction and installation processes. This allows for easy joining of different components, ensuring a strong and reliable structure. 4. Durability: The special steel should be able to withstand the harsh conditions it may be exposed to over its lifetime. It should have high durability to resist fatigue, impact, and other external factors that could potentially compromise the integrity of the infrastructure. 5. Lightweight: While strength is important, special steel used in telecommunications infrastructure should also be lightweight. This enables easier transportation, handling, and installation of the components, reducing costs and time required for construction. 6. Fire resistance: Special steel used in telecommunications infrastructure should have good fire resistance properties to prevent the spread of fire and ensure the safety of the infrastructure and the surrounding areas. 7. Electrical conductivity: Telecommunications infrastructure often requires electrical grounding and bonding. Therefore, special steel used in these applications should have good electrical conductivity properties to ensure effective grounding and minimize electrical interference. Meeting these requirements ensures that the special steel used in telecommunications infrastructure can provide the necessary structural integrity, longevity, and performance to support reliable and efficient communication networks.

- Q:How is high-temperature stainless steel used in the production of gas turbines?

- High-temperature stainless steel is used in the production of gas turbines due to its excellent resistance to corrosion and oxidation at elevated temperatures. It is primarily used to manufacture critical components like turbine blades, vanes, and combustion chambers, which are exposed to extreme heat and pressure inside the turbine. The high-temperature stainless steel ensures durability, performance, and longevity of gas turbines, enabling them to operate efficiently in demanding conditions.

- Q:How does special steel contribute to the renewable energy aftermarket industry?

- Special steel plays a crucial role in the renewable energy aftermarket industry by enhancing the efficiency, durability, and cost-effectiveness of renewable energy systems. One of the primary applications of special steel in this industry is in the manufacturing of wind turbine components. Wind turbines require high-strength and corrosion-resistant materials to withstand the harsh environmental conditions and generate electricity efficiently. Special steel alloys, such as high-strength low-alloy (HSLA) steel and stainless steel, offer superior mechanical properties, fatigue resistance, and excellent corrosion resistance, making them ideal for wind turbine tower structures, rotor blades, and other critical components. By using special steel in wind turbine manufacturing, the renewable energy aftermarket industry can benefit from increased turbine lifespan, reduced maintenance costs, and improved energy output. The strength and durability of special steel enable taller and larger wind turbine towers, allowing for the installation of turbines in areas with lower wind speeds. This expansion of suitable locations helps to maximize the energy production potential, making wind energy a more viable and widespread renewable energy source. Furthermore, special steel also contributes to the renewable energy aftermarket industry through its application in solar power systems. Solar panels require robust mounting structures to support the weight of the panels, withstand wind and snow loads, and ensure optimal sun exposure. Special steel, with its high strength-to-weight ratio and corrosion resistance, is commonly used in these mounting structures, providing long-lasting and reliable support for solar panels. In addition to wind and solar energy, special steel finds applications in other renewable energy systems such as hydroelectric power plants and geothermal systems. These industries benefit from the corrosion resistance and resistance to extreme temperatures offered by special steel, ensuring the longevity and efficiency of the equipment. Overall, special steel significantly contributes to the renewable energy aftermarket industry by enabling the production of reliable, durable, and efficient renewable energy systems. Through its use in wind turbines, solar panels, and other renewable energy technologies, special steel helps to enhance the performance and longevity of these systems, ultimately driving the growth and adoption of renewable energy sources worldwide.

- Q:How does special steel contribute to improved product aesthetics?

- Special steel contributes to improved product aesthetics in several ways. Firstly, special steel can be manufactured with a higher level of precision and consistency compared to regular steel. This allows for the creation of products with smoother surfaces, sharper edges, and more intricate designs. As a result, products made from special steel often have a more visually appealing appearance. Additionally, special steel can be treated or coated to enhance its visual appeal. For example, it can be polished to create a reflective surface, giving the product a high-end and luxurious look. Special steel can also be coated with different colors or finishes, such as chrome or black oxide, to match specific design preferences and create a more visually striking appearance. Furthermore, special steel can be shaped and formed in unique ways due to its superior strength and flexibility. This allows designers to create products with more complex and innovative shapes, resulting in a distinct and eye-catching aesthetic. The ability to mold special steel into various forms also opens up possibilities for creating intricate patterns, textures, and embossed designs on the product's surface. Lastly, special steel offers excellent corrosion resistance and durability, which helps maintain the product's appearance over time. It prevents rust, staining, and other forms of deterioration that can negatively impact the visual appeal of a product. This long-lasting aesthetic quality is especially important for products that are regularly exposed to harsh environments or require frequent handling. In summary, special steel contributes to improved product aesthetics through its precision manufacturing, customizable surface treatments, unique shaping capabilities, and long-lasting visual appeal. These qualities allow for the creation of visually appealing products that stand out in terms of design, finish, and overall appeal.

- Q:What are the different forging techniques for special steel?

- There are several different forging techniques used for special steel, including open die forging, closed die forging, and ring rolling. Open die forging involves shaping the steel between flat dies or anvils, while closed die forging uses shaped dies to compress the steel into the desired shape. Ring rolling involves shaping the steel by rolling it between two or more dies, creating a seamless ring shape. Each forging technique has its own advantages and is chosen based on the specific requirements of the steel product being produced.

- Q:How does special steel contribute to the pharmaceutical aftermarket industry?

- The pharmaceutical aftermarket industry greatly relies on special steel, which offers numerous benefits that enhance the efficiency and quality of pharmaceutical products. Firstly, special steel's resistance to corrosion and wear makes it ideal for manufacturing pharmaceutical equipment like tanks, vessels, and pipelines. This resistance guarantees the equipment's integrity and prevents any contamination of pharmaceutical products. Furthermore, special steel possesses outstanding heat resistance, enabling it to withstand high temperatures without deformation or degradation. This is especially crucial in pharmaceutical manufacturing processes involving heat, such as sterilization or drying. Special steel's heat resistance ensures the equipment remains stable and reliable, ensuring the safety and effectiveness of pharmaceutical products. Moreover, special steel is renowned for its strength and durability, making it capable of enduring rigorous usage in the pharmaceutical industry. This is vital in the aftermarket industry, where pharmaceutical equipment often undergoes frequent repairs or modifications. The strength and durability of special steel facilitate easy maintenance and repair, reducing downtime and costs for pharmaceutical companies. Additionally, special steel offers excellent hygiene properties, as it can be easily cleaned and sanitized. This is of utmost importance in the pharmaceutical industry, where stringent hygiene standards are crucial to prevent contamination or cross-contamination of pharmaceutical products. Special steel's ease of cleaning and sanitization ensures the equipment remains free from potential sources of contamination, thereby preserving the integrity and quality of the products. In summary, special steel significantly contributes to the pharmaceutical aftermarket industry by providing corrosion resistance, heat resistance, strength, durability, and excellent hygiene properties. These characteristics ensure the integrity, safety, and effectiveness of pharmaceutical products, while also minimizing maintenance costs and downtime for pharmaceutical companies. Thus, special steel plays a pivotal role in the overall efficiency and success of the pharmaceutical aftermarket industry.

- Q:What are the different types of tool steels used in special steel?

- Special steel applications commonly utilize various types of tool steels, each designed to possess exceptional hardness, wear resistance, toughness, and heat resistance. These steels are ideal for tooling and cutting applications. Some of the types of tool steels used in special steel are as follows: 1. Carbon Tool Steel: With high carbon content ranging from 0.60% to 1.5%, this type offers excellent hardness and wear resistance, making it suitable for drills, taps, and cutting tools. 2. High-Speed Steel (HSS): HSS is an alloy steel containing elements like tungsten, molybdenum, chromium, and vanadium. It provides exceptional heat resistance, hardness, and toughness, retaining its cutting edge even at high temperatures. HSS is commonly used in drill bits, milling cutters, and other cutting tools. 3. Cold Work Tool Steel: Specifically designed for room temperature or lower temperatures, this type offers excellent toughness, wear resistance, and strength. It is used in blanking, piercing, and forming dies. 4. Hot Work Tool Steel: Developed to withstand high temperatures without sacrificing hardness and strength, these steels possess good thermal conductivity, resistance to thermal fatigue, and deformation. They find applications in forging dies, extrusion dies, and die casting molds. 5. Shock-Resisting Tool Steel: Designed to resist shock and impact loads, this type offers excellent toughness, strength, and wear resistance. It is commonly used in hammers, chisels, and pneumatic tools. 6. Stainless Tool Steel: Stainless tool steels contain high levels of chromium, providing excellent corrosion resistance. They are used in applications where resistance to rust and corrosion is crucial, such as surgical instruments, molds, and cutlery. 7. Powder Metallurgy Tool Steel: Manufactured using a powder metallurgy process, these steels offer precise control over composition and microstructure. They exhibit excellent wear resistance, high toughness, and good machinability, finding applications in high-speed cutting tools and forming tools. Overall, the various types of tool steels used in special steel applications possess a wide range of characteristics and properties to meet the specific requirements of cutting, forming, and tooling applications.

- Q:How does special steel perform in cryogenic conditions?

- Special steel performs well in cryogenic conditions due to its low ductile-brittle transition temperature, high strength, and good toughness. It maintains its mechanical properties and resists cracking or fracture at extremely low temperatures, making it suitable for various applications such as liquefied natural gas (LNG) storage tanks, aerospace components, and cryogenic research equipment.

- Q:How does special steel contribute to the aerospace material weight reduction?

- Special steel contributes to aerospace material weight reduction through its unique properties and characteristics. Special steel alloys such as stainless steel, titanium alloys, and high-strength low-alloy steel offer superior strength-to-weight ratios, allowing for the construction of lightweight yet robust components and structures in aircraft. These steel alloys possess excellent mechanical properties, including high tensile strength, hardness, and corrosion resistance, which enables them to withstand extreme conditions and reduce the need for additional material reinforcement. By utilizing special steel, aerospace manufacturers can design and fabricate lighter aircraft, resulting in improved fuel efficiency, increased payload capacity, and enhanced overall performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grade 316 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords