GPB-90 Type High Pressure Triplex Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

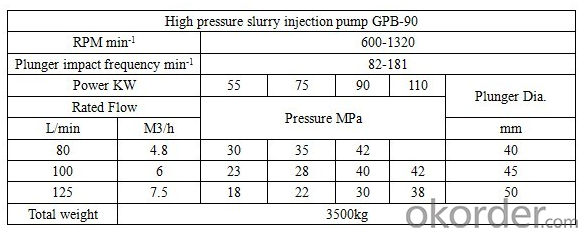

The high pressure triplex pump GPB-90 is widely used now as a power equipment for slurry injection.

◆The special bush structure between crank shaft and connecting rod at power frame

high strength ,strong wear ability ,good lubrication ,small friction coefficient , stable driving at the power end ,lower temperature ,suitable for continuous duty ,operation simple, safely and realiable making the disassembly easier ,saving time and effort

◆It can be used in following fields, the reinforcement in new building, high expressway ,railway, subway and the like, the treatment for old building sedimentation, the construction of waterproof wall for reservoir, dam and engineering, the construction of breast wall, leakage blocking in mine and the wall protection of well ,coal excavation with high pressure jetting, hydraulic liquid supply in well, the large underground pipes cleaning, chemical industry ,stiletto with high pressure water ,other fields as well

◆Technology parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q:should replace timing belt & water pump on a newly purchased used vehicle..if no records of last x changed?

- better to do it now than in the middle of winter when you have no choice good luck

- Q:My car is over heating.the hose that goes to the thermostat is swollen.i wanted to open the radiator to release the pressure but it was too hot ,and too much pressure. is this a sign that the water pump is good?

- First let me say the GOOD LORD was watching over you. You NEVER NEVER NEVER open a radiator cap when it is hot. Had a friend do that and he now has scars on his chest where the water sculled him. Yes it is working. What you need to do is change the thermostat. But please wait until the engine is cool to the touch.

- Q:37KW how many contactors does the pump need to start directly?

- Direct start requires 250A contactor.Contactor is divided into AC contactor (voltage AC) and DC contactor (voltage DC). It is applied to power, power distribution and power consumption. Contactor broadly refers to the use of coils in industrial electricity that flow through the current to produce a magnetic field, so that the contacts are closed so as to control the load of the appliance.

- Q:In the past 9 months, Ive went through 6 or 7 gallons of antifreeze, I was told this was not normal. Ive had my coolant tank flushed 4 times this year, only to be told thats not normal and one lasts a few years. Now that its colder outside my car takes a while to run hot of course, but during the summer it ran hot in about 15 minutes tops. I got a brand new coolant tank before I got another flush because I did have a leak, but that did not combat the problem. I had my radiator looked at and I was told thats fine. So im thinking either a cracked head gasket or a bad water pump...help please. im getting tired of putting money into this car only for the same stuff to keep happening.

- Your better off lifting the gas cap and driving a real car under it.

- Q:I did change water pump before but not on wv beetle?

- For okorder /... Put this in the search box: Volkswagen New Beetle Service Manual: 1998 - 2002. Click then download the pdf file. Good luck!

- Q:I have a 1999 Mercury Grand Marquis vehicle. How do you know when the water pump is going. Is their any particular noise I should be hearing.

- There is no noise associated with a water pump going out that I am aware of other than the engine exploding due to excessive heat. The dash guages; especially the engine temp guage, will give you a clue as to a cooling problem, whcih is what the water pump is for. The water pump prevents the engine block from overheating. When the pump fails, the engine overheats and will either shut down, or the engine will burn out. The best way to tell is to monitor the temp guage. If the engine is running hot, it either the water pump, lack of water in the cooling system, or Thermostat failure. Best to have a mechanic check it out. Cheers!

- Q:i need to know an estimated cost for changing this cars water pumpthanks..

- Too okorder i did this, and by doing so it saved me money, time, and the risk of getting ripped off.

- Q:Yesterday morning I was looking under my hood and I noticed that I was leaking water. It looked like the leak was coming from the water pump.I had to get to work, which is close by so I topped off the radiator and went to work. When I got to work I looked under the car and saw no leaking. I figured the radiator had ran dry although the car hadn't overheated, After work I started to fill the radiator to get home. I saw that I had leaked a little fluid but not much. I topped it off and picked up my son then went home. No overheating. No leaking. Today I've ran several errands and I've had no problems. What do you think was going on with my water pump yesterday?

- If you're seeing the drip from just behind the pulley, the pump seal is probably leaking...while it may not be much now, it will only get worse, so take it to a shop for verification of the leak and replacing the water pump...

- Q:ok some one put sugar in my gas tank i had to replace my fuel pump and now i have sludge that's eating th inside of my radiator hoses and my water pump went and of course that's timing driven and my timing belt is awful tight i cant put a finger in between it ....and my car is not car water so i cant drive it and i don't have money to blow to take it to a shop any help u can offer will help and i know i am going to replace my water pump and info for when i do that will help and answers to the sludge (its like a Vaseline) and how to find out if its in my motor or my brand new radiator ? me plz i am a 18 yr old girl with knowledge about cars and have friends to help me and my mom so any helpp will help and is better then none

- Correct okorder /.... Sugar in the tank, is a MYTH. The problem you have, is NOT due to someone putting sugar in the tank. Secondly, your fuel system doesn't connect at all to your radiator. So, replacing a fuel pump has nothing to do with sludge in your coolant. So, is the sludge in the coolant, or the fuel? Because honestly, your question makes no sense right now. Edit: I didn't correct your spelling. I corrected the fact that you are incorrect about sugar in the tank doing anything. IF anything, it would have clogged your fuel filter. Not your fuel pump. Go read the article.

- Q:mechanic says the bearings are going on the pump, and they might as well replace the thermostat while they are there.my question is he right?do they have to remove the engine to replace either the pump or the thermostat?seems like a lot of $ for a what should be a simple job ($450).thanks for your help!

- The waterpump is very hard to get at to replace it. They do no thave to remove the engine, but they do have to remove a lot of the components to get to the waterpump. And it is a good idea to replace the thermostat while they have all the components removed. That way you can be sure that the thermostat will not be a problem later on. Especially now during winter. I think that is a fair price, unless you can get somebody else to do it other than a pro. It is worth saving your engine. If it gets hot, and you run it, your heads may become warped, your waterpump will give out and will cause much more damage. you will have to replace the pistons , rings, or probably the entire motor. good luck my friend.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GPB-90 Type High Pressure Triplex Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords