Gowel Zinc Alloy Room Door Locks

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 Sets set

- Supply Capability:

- 50000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We have different door lock item for choosing

We also make new locks as per drawing and samples:

1). Material: iron alloy/ stainless steel/ brass/,according to your order.

2). Finish: zinc plated,chrome plated,bright brass plated etc.,according to your order

3). Packaging Detail: Carton,or according to your order.

4). Delivery Detail:30 days after order is confirmed

5). Payment: T/T, L/C

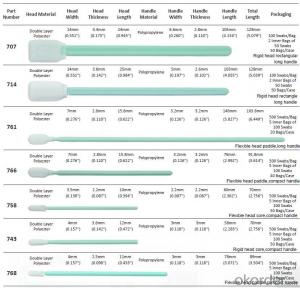

|

Finish |

Code |

|

antique bronze |

AB |

|

antique copper |

AC |

|

brass polishing |

BP |

|

gun black/gold plated |

BN/GP |

|

chrome plated |

CP |

|

gold plated |

GP |

|

matt antique bronze |

MATAB |

|

matt antique copper |

MATAC |

|

brushed finishing /nickel plated |

SN/NP |

|

brushed finishing /gun black |

SN/BN |

|

brushed finishing /chrome plated |

SN/CP |

|

brushed finishing /gold plated |

SN/GP |

|

Materials |

Brass |

Aluminum |

Iron |

Zinc Alloy |

|

Code |

B |

A |

T |

Z |

|

e.g.Z 85 802 Z 172 AB |

|

Z--------------- Plate Material Code 85-------------- Cylinder Hole Distance 802------------- Plate Code -Z--------------- Handle Material Code 172------------- Handle Code AB-------------- Colour |

- Q:My son is 2.5 years old and we still use a Video Baby Monitor in his room. I am due in May with my 2nd child and will also need a Video Baby Monitor in the babies room.My question is.. If I get 2 similar systems, will the channels interfere with each other? Is there a brand that makes Dual Camera systems?Parents that have run into this situation what did you do?I'm not comfortable with not having a monitor in my older son's room just yet. so I really will need two.Thanks for your help!

- This Site Might Help You. RE: Colorado Springs Locks of Love? Does anyone know hair salons in Colorado Springs where I get my hair cut for Locks of Love?

- Q:There's like crazy thunders last night, and my electric fan was on and it made this weird ticking/buzzing sound so I turned it off. Then I sat down and suddenly heard this constant ticking and beating sounds in my left ear (pointed towards my window) then all my hair stood up like goosebumps, but I don't know about my hair on my head cause it's very long. Then I got really scared cause I remember my teacher telling me about the signs that lightning is attracted and might strike.. But I was in my room which is upstairs and I don't even know if my house has lightning rods installed. So I'm not sure if it's even possible to get hit when I'm inside my house but I'm kind of scared cause there's so many possibilities, and plus tonight there's thunder showers again, and so should I even be on my blackberry right now and can I keep it plugged too? (Charging it)Thanks in advance, I'd really like to know if all is possible. And things I should be aware of during thunder storms.

- Yes, but maybe he probably has to be, because maybe he can't afford to spare money on certain things.

- Q:Im travelling to New York from Sydney Australia in December 2008 and i was wondering what i should be aware of travelling around this time of year. I will be leaving mid way through December and will be there for Christmas. So what should I be packing clothes wise as it will be Summer in Austrlia or any other details i should be aware of during my stay in New York for example safety, shopping etc..Any infomation will be great!!

- There are a few programs around to help you do that.

- Q:I cant decide whether to cut my losses and sell now or take my chances, do repair and hope that it runs for another couple of years.even minor repairs on it have been expensive so I hate to think what the big repairs are going to cost.

- Follow Pat F85's instruction plus push, pull, wedge up or down or various combinations of directions to relieve friction and let latch move freely. If that doesn't work, try to wedge a butter knife or something similar behind the part you circled in red. Start as far to the left as you can. You are trying to get it to retract to the right. When you get it open, replace the lockset and internals.

- Q:but is it dangerous? i want to know what exactly to take and what i need need? please explain what need i will really appreciate it

- I would go to the doctor as soon as possible! It could be a sign of something more serious.

- Q:Website to lookup a Lexus part number? Trying to find the Lexus part for a door lock actuator.?

- Hi, 1. It is very simple , Just download My Lockbox and install it 2. Enter a safe password 3.Open it and click on Add then add a folder you want to lock. 4. Then the locked folder become invisible. 5. You can open it by opening My Lockbox Control Panel and clicking on Unlock OORR Just Ctrl+U and enter password. 6. After this your folder become visible.

- Q:I am having my contractor install a gas powered fire pit in my backyard and am supplying the material. My question is can I use schedule 40 stainless pipe and stainless fittings instead of the standard galvanized pipe? I never want to dig a 30ft. trench two feet deep again and feel like I won't have to if I put stainless pipe in. I am not worried about cost because I can buy the pipe at cost and the $100 difference is worth the labor savings.

- Well I certainly miss oxygen getting to my brain but the internet keeps me entertained, which is all any of us can really hope for in life.

- Q:I've been with this girl for about 2 1/2 months now, and things have been absolutely amazing. She is the perfect girl for me and she feels the same about me. We just click about everything and we have so much in common. We talk for a few hours every night on the phone and we never seem to run out of things to talk about. But, recently, we've been having trouble sustaining a conversation. The past couple of nights, we just sit in silence and listen to each other do other things. I know that every relationship has it's down time, but I would just like some advice as to how to get through it or maybe to help the situation. Some ways to ignite the spark again would be nice too. Thanks!

- Talk to your doctor, and perhaps visit/call a vet for the best advice.

- Q:HEres the thing i live in small apt complex. My husbands friend lives across the walkway. He has some issues. mostly self esteem and anger . what a mixture. lately hes been coming over drunk and talking out his a$$ and really just pissing me off. I was putting up with it for my husbands sake. But its getting worse. 2 weeks ago we had friends over the friend came over was already drunki think he drinks everydayanyways he started getting all load and bitching and soon all our friends left. He basically ruined the party so we told him we were gonna go to bed. He got pisst that we didnt want to drink anymore. He was yelling and screaming. i think my husband feels bad for him because hes kinda down on his luckhis own fault if you ask mehe put himself in his situation quitting jobs when he didnt have another onethings like that. His friend gets mad when my husband goes out with his other friends and doesnt invite him. then they have to talk it out for over an hour.

- All set to ride the roller coaster with you don't know if I will watch you spew but if it makes you feel better You can take me on the spinning rides and watch me puke.

- Q:Howdy,I installed a Watts-Premier reverse osmosis water filtration system this past weekend. So far, it all works finehowever I'd like to connect my ice maker to it. The water filtration using 1/4 tubing with those push-in Quick Connect fittings. And my ice maker already has a 1/4 stainless steel flexible supply line running to the fridge.Watts recommends not using copper fittings or piping with a reverse osmosis system, so I need to stick to plastic connections. I went to OSH this morning and found a brand of fittings called EZCON-X. I had no problem finding a tee and an inline valve to split the reverse osmosis supply line and add a shutoff switch. But the problem I'm having is finding a way to connect that to the ice maker line. The tee has a 1/4 male threaded end, but the 1/4 female end on the ice maker line is too small.So any suggestions as to what I should be looking for? How does one easily connect stainless steel tubing to a plastic connector?Thanks!

- you can get door locks for your s10 at autoparts stores if one doesnt have them, then try another store. the part number is DL15250 there made by lock works there owned by borg warner which makes after market replacement parts for many vechicles. and they come in either black or chrome. or if you cant find any one who can get them and your old ones are in good working condition try a lock smith and just have the rekeyed.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai,China |

| Year Established | 1998 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 60.00% Eastern Asia 15.00% Eastern Europe 10.00% Northern Europe 5.00% South Asia |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | ShangHai |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Gowel Zinc Alloy Room Door Locks

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 Sets set

- Supply Capability:

- 50000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords