Good Woven Geotextile Fabrics for Dam-CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 10000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

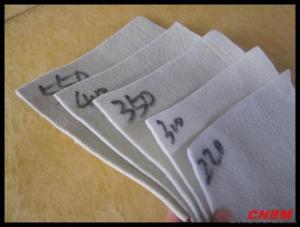

Our company produces all kinds of Geotextile,like 4-6m width,thickness 80-400 g/square meter.machine woven geotextile.It's widely applied to road,railway,water conservancy project.

Feature:

1. High tension.Because it's made of Plastic flat yarn,it can keep enough tenacity and stretching.

2. Non-corrosive.It can be non-corrosive for long time in soil and water with different PH value.

3. Good Water Permeability.There is space between flat yarn,so it has good water permeability.

4. Good antimicrobic. For organisms,there will be no worm-holes.

5. Easy construction.Because of light material,soft,it's easy for transportation,spreading out and construction.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

- Q:What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by interlacing yarns or fibers together, creating a strong and durable fabric. They have a high tensile strength and are commonly used for applications that require high load-bearing capacity, such as stabilizing soil or preventing erosion. Non-woven geotextiles, on the other hand, are made by bonding fibers together using heat, chemicals, or mechanical processes. They are generally less strong and more flexible than woven geotextiles. Non-woven geotextiles are often used for filtration, separation, or drainage purposes, where their permeability and ability to retain fine particles are important factors.

- Q:Can geotextiles be used in the protection of culverts?

- Yes, geotextiles can be used in the protection of culverts. Geotextiles are often used as a protective barrier around culverts to prevent soil erosion and filter out any sediments that may clog or damage the culvert. They provide an effective solution for enhancing the longevity and stability of culverts.

- Q:What are the different functions of geotextiles in geoenvironmental engineering?

- Geotextiles serve various functions in geoenvironmental engineering, including erosion control, soil stabilization, drainage, filtration, and reinforcement. These materials prevent soil erosion by acting as a barrier against water flow and wind forces. They also stabilize soil by improving its mechanical properties, preventing soil movement and settlement. Geotextiles facilitate drainage by allowing water to pass through while retaining soil particles. They serve as a filtration layer, separating different soil layers and preventing the migration of fine particles. Additionally, geotextiles are used for reinforcement purposes, enhancing the strength and load-bearing capacity of soil structures.

- Q:Are geotextiles suitable for use in drainage ditches?

- Yes, geotextiles are suitable for use in drainage ditches. They are commonly used as a filter fabric to prevent soil erosion and retain sediment, while allowing the passage of water. Geotextiles also help in distributing the flow of water evenly throughout the drainage ditch, improving its efficiency and preventing clogging.

- Q:Do you want to use glue to connect the geotextile?

- Shuo earth geotextile production of drainage board geotextile, Manager Li

- Q:Can geotextiles be used in landscaping projects?

- Yes, geotextiles can be used in landscaping projects. Geotextiles are often used as an effective way to control erosion, stabilize soil, and separate different layers of soil or aggregates in landscaping applications. They can be used for retaining walls, slope stabilization, weed control, and drainage systems, among other purposes.

- Q:Pvc waterproof board and geotextile must be used with what

- To stick together, I specialize in producing pvc waterproof board and geotextile and other geotextile materials

- Q:Are geotextiles resistant to abrasion?

- Yes, geotextiles are generally resistant to abrasion. They are designed to withstand rubbing, friction, and wear caused by external forces, making them highly durable and suitable for various applications that involve exposure to abrasive forces.

- Q:I was just doing anti-seepage film and geotextile clerk do not know how to find this project? add me

- Where are you from?

- Q:Geotechnical deployment of aging detection of what indicators

- Material anti-aging performance testing, if the reality to consider, for too long, are generally used in the laboratory to accelerate the aging approach to consider. Aging the concept of aging is a big concept. Refers to the material in the external environment under the influence of time changes. Environmental effects are multifaceted, the role of light, the role of temperature, a chemical role, the role of micro-organisms and so on. Now generally referred to as aging, refers to the light aging. Light aging, refers to the material in a certain light exposure after a certain period of time after the performance of the material changes. The most commonly used indicator for photoaging is the strength retention of the material. That is, the ratio of the strength that remains after the light is retained.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good Woven Geotextile Fabrics for Dam-CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 10000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords