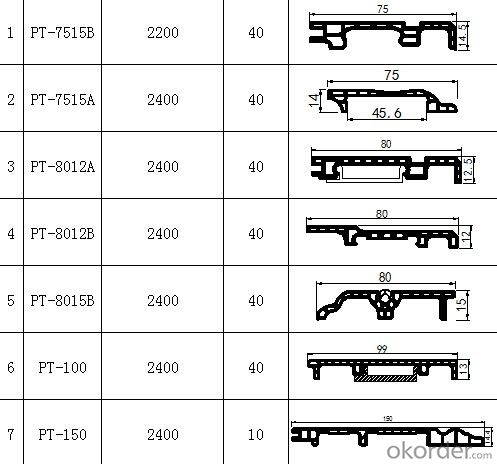

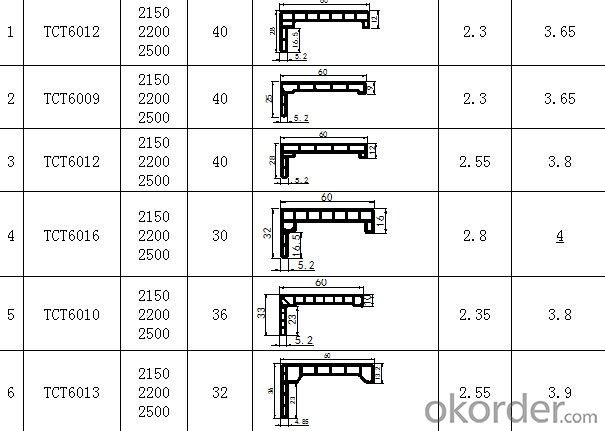

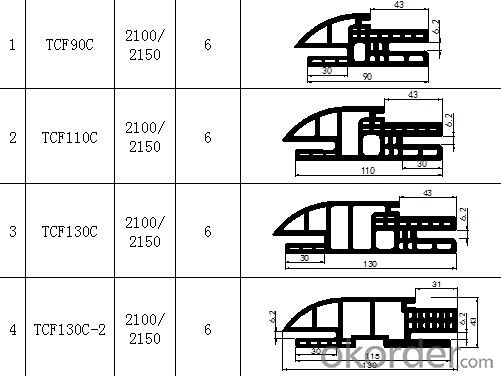

Good Quality PVC Door Frame TCS 150 Various Profile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m

- Supply Capability:

- 200 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our factory is divided into twelve production lines. We use production equipment from Germany including mixers and double screw rod extruding machines. Our monthly capacity is 500 tons of wood plastic composites--80% of which we export.

We have an R&D department with 5 engineers who have an average of 10 years of experience. They research and develop our equipment, including the mixer, assembly line, QUV experiment meter, multi-purpose impact reflectoscope, dresser and knurling machine. We develop at least one new product every month and can prepare OEM samples for you with a lead time of one month.

We have a QC department with five engineers who have an average of four year's experience. They examine products before export using reflectosopes and ensure our facilities conform to ISO 9001 and ISO 14000 certification standards. The products was tested by third party(INTERTEKS, SGS), meet REACH’S regulations.

Our company adheres to “Quality first, Customer first” philosophy, in line with “The good faith management” principle of service, looking forward to cooperating with you.

- Q:My side of the wall paint 5 years of the top there are cracking the place, I want to shovel them to re-brush latex paint, but the floor of the floor I do not want to move, afraid of the construction of the workers when the workers hit bad, how can I do? Question added: the home there are a lot of furniture, it can not move, the bedroom bed closet, the living room of some have, how can I protect up ah. More

- To be protected, to the market to buy ordinary board full of shops on the floor, and between the floor to add a layer of 2MM thick foam pad, before the bubble to confirm the floor clean, no hard particles, The box is sealed with a patchwork between the plates.

- Q:Autoclaved aerated concrete block construction requirements in the doors and windows on both sides of the puzzle and blocks and other high-width C15 prefabricated concrete block, what is the length of it?

- Length is generally 10cm ~ 15cm, specification is not required

- Q:How to deal with waterproof coatings on aluminum windows

- Is the decoration finished splashing above? Can be washed with water. It is best not to use a sharp knife, do not use corrosive chemical products wash.

- Q:Aluminum doors and windows production, installation need to pay attention to what? What are the technical requirements?

- In the process of making the technical staff to do every standard process, because the aluminum alloy doors and windows waterproof performance itself is not waterproof profiles, it must be used for each connection point waterproof film, glass must be sealed with glass glue inside and outside

- Q:What do all the walls make gypsum board grasses mean

- Should be "all the walls to do gypsum board grassroots" after this sentence there are features that can be listed together?

- Q:Plastic window is how to do ah?

- Plastic co-extruded profiles to achieve the integrated production of sealing strips and profiles, significantly improved the plastic doors and windows of the watertight, air tightness and anti-aging, anti-permeability, to overcome the steel doors and windows in the production process after the sealant There are shrinking, seams and other defects, not only for the steel doors and windows assembly business to save the assembly process and time, but also reduces the cost of materials, greatly improving the production efficiency.

- Q:Paving mosaic construction process

- Double gull nostalgic mosaic can be used for indoor and outdoor floor and wall decoration. For construction paving, the most critical job is to prepare the surface of the site. Tiles must be in the horizontal and vertical angle are accurate and accurate paving, so as to avoid problems. Paving the surface must be clean and dry. Paving materials: the market has a professional mosaic tile adhesive and sealing agent, there are two-in-one tile glue. Color is also a variety of points, according to different needs with the use of cement and sealant. The most widely used is white and black. Paving tools: grouting floating, large bucket, V-shovel, hammer, small bucket, pliers. Paving steps: 1. In the vat inside the mixed powder-like mosaic tile glue, stirring at the same time by adding water until peanut butter to achieve similar viscosity. 2. In the construction of the wall, then use the v-type shovel. Each post a paste From the middle of the patch area to start paving out. In the wall with the horizontal line and the vertical line for the mark, you can make the gap between each paste evenly. Hand the appropriate force to the mosaic into the tiles inside, so that mosaic and ceramic tile full contact. 3. Paste finished or close the mosaic, you need to paste a paste on the match mosaic. With a piece of wood and a hammer, gently tapping to adjust the position of the mosaic. Need to pay special attention to the edge and connection of each mosaic. 4. If necessary, adjust the mosaic position in time before the mud is dry. 5. Allow the mud to have a 24 hour posture before filling. 6. Dry the sealant for 10-20 minutes, then gently wipe the mosaic surface with a piece of wet sponge. 7. Finally, wipe with a piece of lint-free cloth out of the mosaic surface of the remaining cement and caulking agent.

- Q:What are the steps behind the construction of the building after the closure?

- 1, parapet masonry, stucco 2, the roof to find slope 3, roof leveling layer 4, roof waterproof 5, waterproof protective layer

- Q:The installation of the horizontal lines, vertical lines and out of the line, respectively, what is the use of what in the end

- The horizontal line of the window to determine the level of the installation of the window; entry and exit line on the window side and the inner wall of the flat, or highlight the size (press Decoration requirements), steel windows, aluminum windows every wall center line.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good Quality PVC Door Frame TCS 150 Various Profile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m

- Supply Capability:

- 200 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products