Good Quality Light Duty PVC/PU Conveyor Belt For Industrial Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good Quality Light Duty PVC/PU Conveyor Belt For Industrial Use

PVC Conveyor Belt&PU Conveyor Belt

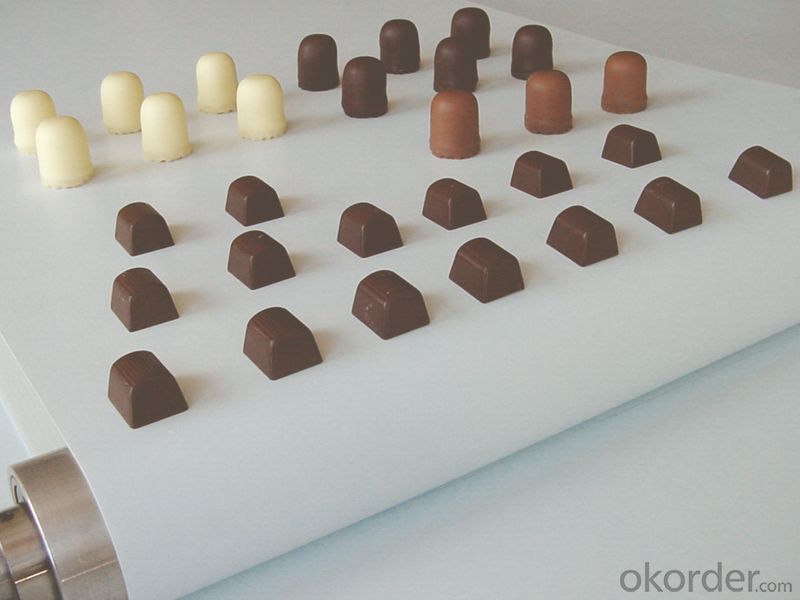

Material: PU,Shape: plain (flat surface),Thickness: 1mm

Specifications: one ply fabric-one ply PU

Tensile strength: >150N/mm

Temperature range: -10°C~+90°C

Color: white

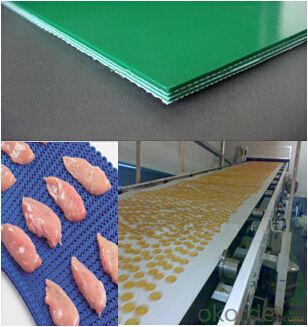

Applications: conveyance and production assembly lines in the areas of cigarettes, foodstuffs, electronics, pharmaceuticals, drinks and papermaking Specification.

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

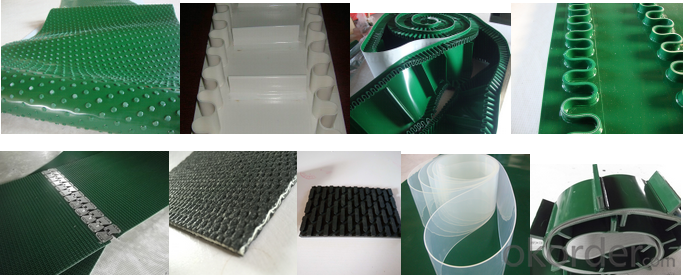

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

Product Pictures:

Our Company:

Pls contact me freely if any inquiry,thank you!

- Q:How do olive nets impact the overall health of the olive tree?

- Olive nets play a crucial role in protecting olive trees and promoting their overall health. By covering the tree canopy, these nets shield the olives from extreme weather conditions, pests, and birds, preventing damage to the fruits. This protection ensures that the olives remain healthy and free from diseases or infestations. Additionally, olive nets facilitate better air circulation around the tree, reducing the risk of fungal growth and promoting overall tree health.

- Q:Can olive nets be custom-made?

- Yes, olive nets can be custom-made to meet specific size and shape requirements for various olive groves.

- Q:Can olive nets be repaired if damaged?

- Yes, olive nets can be repaired if damaged.

- Q:Do olive nets affect the appearance of olive trees?

- Yes, olive nets can affect the appearance of olive trees. When olive nets are placed over the trees to collect the olives during the harvesting season, they can change the overall look of the tree by covering its branches and obscuring the natural shape and foliage.

- Q:How do you dye plastics?

- This method is basically the same as the extrusion dyeing method. The difference is that the proportion of the dye in the plastic is 10 times higher than that of the usual one. It can be used more frequently when the plastic is injected

- Q:How do olive nets prevent olives from being damaged by small mammals?

- Olive nets prevent olives from being damaged by small mammals by creating a physical barrier that prevents the animals from accessing the trees or the ground beneath them. The tightly woven mesh of the netting acts as a deterrent, making it difficult for the mammals to reach and consume the olives. Additionally, the nets are often installed at a height above the ground, making it even harder for the animals to climb up and reach the olives. Overall, olive nets serve as a protective shield, keeping the olives safe from potential damage caused by small mammals.

- Q:Can olive nets be used for olive tree nutrient retention?

- No, olive nets are primarily used for harvesting olives and protecting the fruit from birds, not for nutrient retention.

- Q:Can olive nets be used in combination with windbreakers?

- Yes, olive nets can be used in combination with windbreakers. The windbreakers provide protection against strong winds, while the olive nets help prevent birds and other pests from damaging the olive trees.

- Q:Are there any specific guidelines for using olive nets on olive trees with delicate branches?

- Yes, there are specific guidelines for using olive nets on olive trees with delicate branches. It is important to choose a net with a fine mesh size to prevent any damage to the delicate branches. Additionally, the net should be properly secured to avoid any entanglement or breakage of branches. Regular monitoring and adjustment of the net is also necessary to ensure it is not causing any harm to the tree.

- Q:Are there any alternatives to olive nets for harvesting olives?

- Yes, there are alternatives to olive nets for harvesting olives. Some common alternatives include manual handpicking, using long-handled rakes or combs to remove olives from the branches, and mechanical harvesters that shake the trees to dislodge the olives. Each method has its advantages and disadvantages depending on factors such as tree size, terrain, and the desired quality of the harvested olives.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good Quality Light Duty PVC/PU Conveyor Belt For Industrial Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords