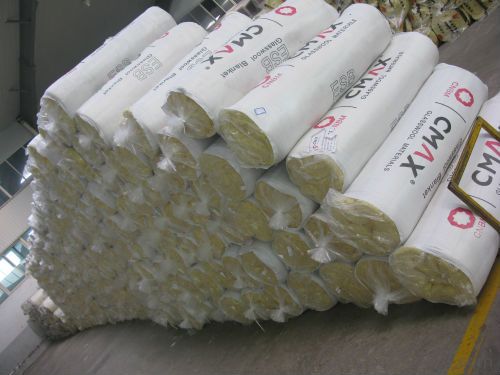

Good Insulation Glass Wool Blanket Kraft Paper Faced For Drywall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Description

Glass wool blanket is in flexible form for ease of installation over large areas. Both products are available to order with a wide range of density and thickness, and with various types of facing applied.

Standard Size

Item | Unit | Index |

Density | Kg/m3 | 10 - 48 |

Thickness | mm | 25-150 |

Width | mm | 1200 |

Length | mm | 5000-30000 |

Remark:

Other sizes available upon request Facing materials can be applied upon request

Technical Data

Item | Unit | Index |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Thermal Conductivity ( 25℃) | W/mK | 0.038- 0.045 |

Reshrinking Temp | ℃ | ≥250 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

Application

Glass Wool are widely used in public, commercial and residential buildings as well as industrial plants, for applications such as roofing, external wall, partition wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

Material:

Double layers of aluminum foil reinforced with high tensile spring steel wire

Structure: High elastic wire, aluminum foil. A reinforcement model can be required.

Aluminum foil thickness: 0.035mm

- Q:Are fireproof glass wool and centrifugal glass wool the same?

- Although both of which are glass wool, there are main three types of products involved. Centifugal glass wool includes hydrophobic glass wool and ordinary glass wool. Centrifugal glass wool is produced from centrifugal injection. The centrifugal glass wool you said is only a general name, and it also belongs to centrifugal glass wool material.

- Q:What are the differences between glass wool and natural cotton? Are there any differences when touching?

- Burn it.

- Q:If the glass wool is used for thermal insulation outside seamless steel tube, should the pipe be rust-proof and sprayed paint?

- It doesn't matter if you odn't brush rust-proof paint and ready mixed paint. If you have brushed rust-proof paint on seamless steel tube, it is OK without ready mixed paint, but it will shorten the operation life of the steel pipe.

- Q:Are foam glass and glass wool the same?

- Not the same. Glass wool is made of asbestos tile. Foam glass is a kind of glass.

- Q:What is the difference between glass wool and rock wool?

- In the high-speed operation of the centrifuge driven, the high-speed operation of the centrifuge glass will be thrown into a glass flow, the role of high-temperature high-speed flame, the glass stream is further drawn into fiber,

- Q:Does glass wool belong to the asbestos insulation material?

- No, it isn't. Asbestos thermal insulation materials and glass wool insulation materials are two completely different products.The main function of asbestos products is heat insulation. General products are of it are asbestos cloth, asbestos ropes,asbestos packing, asbestos thermal insulation plates, asbestos velvet, sepiolite, asbestos mats, asbestos quilt,asbestos rubber sheet, PTFE products,metal spiral wound gasket, asbestos paper and asbestos lines added with steel wire.Amomg these, asbestos thermal insulation board can be thermal insulating. The main function of glass wool products is heat perservation. It has a certain heat resistance, but is not as good as asbestos thermal insulation material.Glass wool products are glass wool board, pipe and mat.

- Q:What are the specific differences between glass wool board and glass fiber board?

- Thus, the full name of glass wool is glass fiber wool: There are two kinds of glass fibers from the uses of fiber glass. The fiber used to weave is the continuous fiber, continuous fiber and staple fiber, and the fiber used to make cotton is staple fiber, glass wool board is equivalent to glass fiber board. You are reminded by the Shouchuang Decoration

- Q:Whose thermal insulation performance is the best between glass wool felts and cystosepiments?

- The construction methods are different. The cystosepiments are certainly better than glass wools. But cystosepiments are rigid plates, while the glass wool felts are soft. From the thermal insulation property,

- Q:Is the glass wool used in curtain wall the thermal insulation wool?

- The glass wool used for curtain wall is thermal insulation wool.However, due to the need of fireproofing, the thermal insulation material for curtain wall normally is rock wool.

- Q:Which one among polystyrene?boards, rock wool boards and glass?wool?boards is the best materials for external wall thermal insulation?

- Polystyrene?boards are better in terms of external wall thermal insulation materials but now polystyrene?boards are not allowed to use. Rock wool and glass wool can be used, but they need good waterproofing treatments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good Insulation Glass Wool Blanket Kraft Paper Faced For Drywall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords