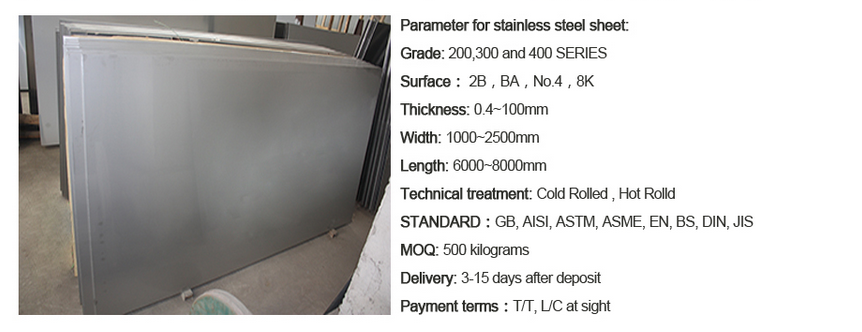

Gold supplier 201 304L 316 316L 304 stainless steel plate price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What are the different grades of stainless steel pipes?

- There are several different grades of stainless steel pipes, including 304, 316, 321, and 410. Each grade has its own unique properties and is used for specific applications based on factors such as corrosion resistance, strength, and temperature resistance.

- Q:Can stainless steel pipes be galvanized?

- Indeed, it is possible to galvanize stainless steel pipes. Galvanization refers to the application of a safeguarding zinc coating on steel or iron to thwart the occurrence of rust. Although stainless steel already possesses a high level of resistance to corrosion, galvanization can serve as an extra layer of defense in specific situations. However, it is worth mentioning that galvanizing stainless steel pipes is not as prevalent as galvanizing carbon steel pipes since the innate corrosion resistance of stainless steel is generally satisfactory for most applications. Moreover, the process of galvanizing stainless steel can modify its visual appearance and may not be suitable for certain aesthetic prerequisites.

- Q:What is the tensile strength of stainless steel pipes?

- The tensile strength of stainless steel pipes can vary based on the specific grade and composition of the steel. However, stainless steel is renowned for its high tensile strength, making it a popular choice for various applications that demand sturdy and long-lasting pipes. On average, stainless steel pipes possess a tensile strength that falls within the range of 500 to 1500 megapascals (MPa). Thanks to this remarkable tensile strength, stainless steel pipes can endure substantial pressure and stress, rendering them suitable for utilization in industries like construction, oil and gas, chemical processing, and automotive manufacturing. It is worth noting that the precise tensile strength of stainless steel pipes can be influenced by factors such as the manufacturing process, heat treatment, and any additional alloying elements present in the steel. Consequently, referring to the specific technical specifications or standards for the particular grade of stainless steel pipes is crucial in order to ascertain their exact tensile strength.

- Q:Are stainless steel pipes suitable for fertilizer industries?

- Fertilizer industries find stainless steel pipes to be suitable. Stainless steel possesses a high level of corrosion resistance, a crucial characteristic for industries where pipes regularly encounter corrosive substances like fertilizers. Moreover, stainless steel pipes exhibit exceptional strength and durability, enabling them to withstand the demanding conditions of fertilizer production. Their smooth inner surface prevents the accumulation of sediments and impurities that might compromise fertilizer quality. Additionally, stainless steel pipes are effortless to clean and maintain, meeting the hygiene and safety standards mandated by the fertilizer industry. All in all, stainless steel pipes are an outstanding choice for fertilizer industries due to their corrosion resistance, strength, durability, and ease of maintenance.

- Q:Are stainless steel pipes suitable for chemical reactors?

- Yes, stainless steel pipes are suitable for chemical reactors. Stainless steel is known for its excellent corrosion resistance properties, making it an ideal choice for handling various chemicals and acids in a reactor system. Additionally, stainless steel pipes offer high strength, durability, and heat resistance, ensuring safe and efficient operation in chemical processes.

- Q:What is the difference between seamless and hot-finished stainless steel pipes?

- Seamless and hot-finished stainless steel pipes are both used in various industrial applications, but they have some key differences. The main difference between seamless and hot-finished stainless steel pipes lies in their manufacturing process. Seamless pipes are made by piercing a solid steel billet to form a hollow tube without any seams or joints. This process ensures a consistent wall thickness throughout the pipe and a smooth interior surface. On the other hand, hot-finished pipes are created by heating a solid billet and then rolling it to form a tube shape. This rolling process can result in a seam or weld line along the length of the pipe. Another significant difference between seamless and hot-finished stainless steel pipes is their dimensional accuracy and surface finish. Seamless pipes are known for their high dimensional accuracy and excellent surface finish, making them suitable for applications where a precise fit and smooth flow are critical, such as in the pharmaceutical or food processing industries. Hot-finished pipes, although generally not as precise in terms of dimensions and surface finish, are more cost-effective and widely used in applications where tight tolerances are not required, such as in structural or construction projects. In terms of strength and durability, both seamless and hot-finished stainless steel pipes offer excellent performance. However, seamless pipes tend to have higher strength due to their manufacturing process, as there are no weak points or potential areas of failure like welded seams. This makes seamless pipes preferred in applications that require high pressure or corrosion resistance, such as in oil and gas pipelines or chemical processing plants. In summary, the main differences between seamless and hot-finished stainless steel pipes lie in their manufacturing process, dimensional accuracy, surface finish, and strength. Seamless pipes are produced without any seams or welds, resulting in superior dimensional accuracy and surface finish, making them suitable for precise applications. On the other hand, hot-finished pipes are more cost-effective and widely used in applications where tight tolerances are not crucial. Both types of pipes offer excellent strength and durability, but seamless pipes are generally preferred in high-pressure or corrosive environments.

- Q:What is stainless steel pipe made of?

- Stainless steel pipe is primarily made of an alloy consisting of iron, chromium, and other elements such as nickel and manganese. The exact composition of stainless steel pipes may vary depending on the grade or type of stainless steel being used. Generally, stainless steel pipes have a high chromium content (at least 10.5%) which provides excellent corrosion resistance and durability. The addition of other elements helps to enhance various properties of the stainless steel pipe, such as strength, heat resistance, and weldability. Overall, stainless steel pipes are made of a strong and versatile material that is resistant to corrosion, making them suitable for a wide range of applications in industries such as construction, automotive, and manufacturing.

- Q:What is the difference between Schedule 10 and Schedule 40 stainless steel pipes?

- Schedule 10 and Schedule 40 stainless steel pipes differ primarily in their wall thicknesses and pressure ratings. Schedule 10 pipes possess thinner walls when compared to Schedule 40 pipes. Consequently, Schedule 10 pipes are ideal for applications with lower pressure ratings and are commonly employed for lighter-duty tasks. Conversely, Schedule 40 pipes boast thicker walls, rendering them suitable for applications necessitating higher pressure ratings, frequently utilized in heavy-duty or industrial settings. The selection between Schedule 10 and Schedule 40 stainless steel pipes depends upon the particular requirements of the application, encompassing pressure, temperature, and material compatibility.

- Q:Can stainless steel pipes be used for power plants?

- Yes, stainless steel pipes can be used for power plants. Stainless steel is often chosen for power plant applications due to its high corrosion resistance and ability to withstand high temperatures and pressures. Power plants typically deal with aggressive environments and require materials that can withstand the conditions without deteriorating. Stainless steel pipes provide excellent resistance to corrosion from chemicals, gases, and water, making them ideal for power plant applications. Additionally, stainless steel pipes have low maintenance requirements, reducing downtime and overall cost.

- Q:Can stainless steel pipes be used for ornamental purposes?

- Stainless steel pipes possess the ability to serve ornamental functions. With its adaptability and contemporary allure, stainless steel emerges as the ideal material for embellishing purposes. Its resistance to corrosion and durability render it an exceptional choice for outdoor installations or environments with high humidity, where alternative metals may deteriorate over time. Stainless steel pipes can be shaped and sized in a multitude of ways, enabling the creation of imaginative and aesthetically pleasing designs. They find common application in architectural structures, such as railings, handrails, and balustrades, as well as decorative furniture, lighting fixtures, and artwork. Moreover, stainless steel pipes can be polished or finished in diverse manners to accentuate their appearance and achieve desired decorative effects. All in all, stainless steel pipes deliver a resilient and visually captivating solution for ornamental purposes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gold supplier 201 304L 316 316L 304 stainless steel plate price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords