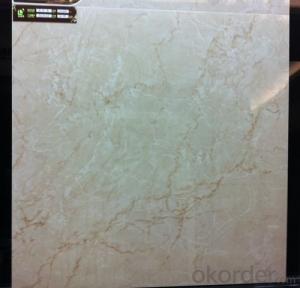

Glazed Porcelain Floor Tile 600x600mm CMAX-Y6001

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information:

Tile Type | Glazed Porcelain Tile, floor tiles |

Certificate | ISO13006, ISO9001 |

Finish | Matte Finish, Lapato Finish, Rough Finish |

Size | 60x60 mm |

Selection Range | Several Colors available |

Features:

1) Unique natural sandstone image designs and exclusive quality;

2) Used for indoor & outdoor wall and floor decorations, as well as Stair Case Product;

3) Easy to install, anti-dust, washable, acid-proof, alkali-proof, durable

4) Material: porcelain

5) Basic size: 600x600x9.8mm, 100x600mm, 150x600mm, 300x300mm, 300x600mm available based on clients’ requirements;

6) Available dimensions

Material | Porcelain |

Dimension | 600x600x9.8 mm |

Packing | Carton + Wooden Pallets |

Finish | Glossy, over 90 degree. |

Usage | Floor and wall |

The glazed porcelain tile is widely used for interior house flooring, hotel lobby flooring, exclusive brand showroom, clubs villas as well as other public sites.

We could go with OEM model, making 2nd production based on client’s requirement;

We could offer flexible service on shipment and better support on payment term;

Our quality guarantee is based on the strict production procedure, quality controlling on the shade, straightness as well as 2nd production and final package.

Specification and technical parameter:

· Matte Finish, Lapato Finish, Rough Finish

· Water absorption:<0.1%< span="">

· Anti-Resistance: R10

· Delivery Time: within 15~20 days after order confirmation.

· Package standard: 4pcs/carton, 40 Cartons/pallet, 32 Kgs/Carton.

- Q:Im looking into renovating our kitchen and thought i would cut some costs with doing some renovating ourselves. Is tiling easy to do yourself, how is it done and what surfaces can they be laid on?Thanks

- Tiling is pretty easy, but the easiest way to find out about it is to go to Home Depot or Lowes and buy a book for approximately $20.00 that will give you step by step help. Then, if you still have questions, the people that work at the pro desk can usually help you the most. Unfortunately, it is hard to explain when you need to see some of the things. You will need a special tile cutter to cut the tile, and a trowel and a bag of spacers. Then get yourself the tile, the thinset to glue the tile and the grout to go in between it. You can lay it directly on concrete. If you have a wood floor, they recommend a hardy backer board between the wood and the tile. You can get by without the backer board if you're very careful. When done, you will need to apply a sealer to the grout.

- Q:Meaning, I was just wondering if you can lay a thin set of mortar then place vinyl tiles on it, and then grout it? This mabye a stupid question and most people would say why not just use real tile if your going to go through all that trouble, but just wondering?.Thanks

- no you can't vinyl tiles and ceramic tiles are too different materials,the cement would corrode the vinyl tile,not a smart idea.

- Q:My house is 55 years old. They had vinyl floring in the bathroom. We wanted to replce the flooring but when we hauled up the vinyl, theres 2inch ceremic tiles underneath. I think the vinyl was glued down because the tiles are a mess. We bought some vinyl flooring to put back down. Whats the best way to do this? We were going to but 1/4 round but now the floors are tile underenath, and the walls are tile as well so we can‘t nail it in.

- Clean the tiles and make sure the surface is completely smooth, laying tile over tile is actually an ideal surface, if you're not at bare wall. Use flooring adhesive, if the tiles you bought are glueless - then use a sealer, reapply once a year or whatever the sealer recommends for reapplication. You can always tile subfloor panels and lay that directly over the tile that's already there - glue (with construction adhesive)or nail the subfloor down. But that's an extra expensive for the subflooring.

- Q:Ok my room has asbestos on the vynil tile floor and it‘s in good condition. I‘m trying to put a carpet on top of the floor is it possible without removing the tile? Home Depot wants me to remove it before they install the carpet.

- was your floor installed in the 60s or before? if not chances are it isn't asbestos

- Q:IAM REDOING MY KITCHEN FLOOR. IS PEEL STICK TILE GOOD FOR THE PROJECT N WILL IT LAST? THANKS

- If you do your prep work right, this is a decent floor finish. Level any imperfections (floor leveler) and , thoroughly, clean the area that you are laying tile in. This can be an inexpensive flooring solution but more expensive, higher quality tile, will give you years of use and abuse.

- Q:Bathroom Tiling Job?

- I would put down a backer board of some sort. It goes by several names, but cement board is one generic version, I think. Hardi-backer is a brand name. When I did my bathroom floor, I screwed down quarter inch boards, and tiled over that. Check carefully to see that you don't end up with a finished floor height that interferes with doors. Also - you may have to extend the height of the toilet flange so that you get a good seal, as the wax ring may not be enough once you raise the floor level.

- Q:The tile is one week old. I have had the company pull tiles, regrout and patch. I have new cracks every day. Can I reasonable ask them to start over?

- It is possible bad mortar was the problem, but my money is on human error. Too little mortar or too few screws in the cement board are common culprits. I would have someone who knows about laying tile(other than the installers) take a look at it and offer up some probable causes. Good luck.

- Q:How to identify the quality of ceramic tile and standard

- Precautions: 1. When the decoration of the house, choose the right material is very important, when people buy tiles, often businesses will use this method to guide consumers to identify the quality of tiles: water seepage, water absorption is high, , Water absorption is low. 2. When purchasing tiles, be sure to identify the quality of the tile, select the regular product and with the correct identification method, pay attention to the construction of tiles to comply with product use instructions, to avoid the wrong method led to tile deformation and loosening.

- Q:hi i live in a upstairs flat,and i want to tile my hall with ceramic tiles,i did a square 4 foot patch to see if the tile would stick or would come loose,well they did come loose,so how do i prepare floorboards for tiling over so the grout wont crack when i walk on the floor thanks

- First, I'd recommend making sure that the wood flooring is secure with no loose spots. Then you may need to strip any finish off it in insure good adhesion. Finally, you'll need to make sure you have a good tile cement and use a proper tile trowel to apply the cement. It will put grooves in the cement that will help with adhesion. If you go to Home Depot or Lowes, they can probably give you pointers. They also have classes sometimes, including putting down tile. Good luck.

- Q:There are thousands of individual tiles. If one falls off or something like that does everything burn up? thanks and how did the heat shield not work for the shuttle in 2003? it might have been in 2001 i have to ask my science teacher

- It depends on where the tile is, and when it comes off. In the case of the Columbia accident in 2003, it actually wasn't the tiles--it was one of the carbon-carbon panels on the leading edge of the wing that got hit by a briefcase-sized hunk of insulation off the external tank, and got a hole blown in it. During reentry, the hole allowed hot gasses to enter the structure of the left wing. The heat caused the aluminum used in making the wing to weaken and fail. There are two kinds of tiles used, in addition to the carbon-carbon panels on the leading edge of the wing and the nose. The black tiles that you see on the underside and coming up the side of the fuselage are for areas of greater heating, while the white tiles protect areas where there is less heating. Losing a tile has two possible problems. If the tile is directly over a critical area (say a hydraulic line), you may get burn through and cause the line or whatever to fail. Popping off a tile also changes the way that air flows around the shuttle. It's possible that the turbulence from one missing tile can cause others to come off in what is called the zipper effect. The more tiles you lose, the greater the chance that you're going to lose a critical tile. Also, if you lose enough of them, it's possible that the shuttle might become aerodynamically unstable, and impossible to control. I don't recall any of the flights having a problem with burn through even though tiles have been lost or damaged on just about every flight

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-Y6001

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products