Glass Wool For Oven

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 1000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool Blanket for thermal Insulation

1.Structure of Glass wool Blanket for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. It is available through home supply stores and manufacturers can also produce wools for special purposes, like insulation in aircraft, where the standards may be higher for health and safety reasons. Numerous companies make glass wool products along with lines of other insulation materials for a variety of applications.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

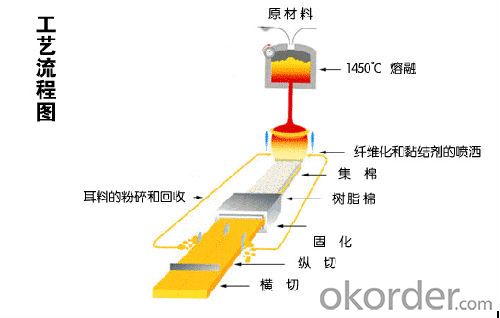

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

2.Main Features of Glass wool Blanket for thermal Insulation:

The glass wool Blanket is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

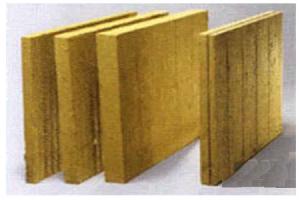

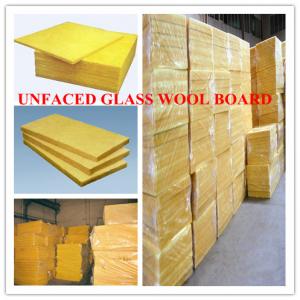

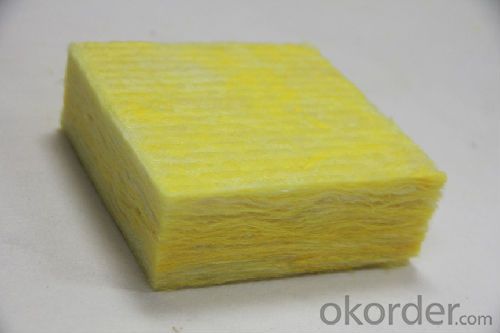

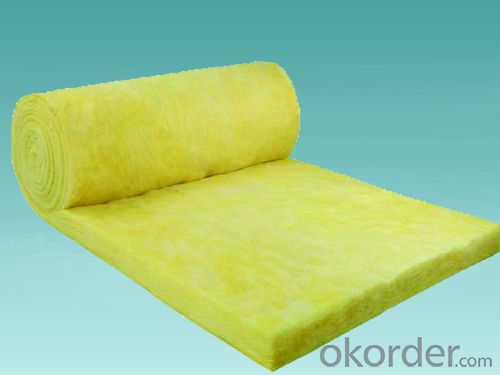

3. Glass wool Blanket for thermal Insulation Images

4. Glass wool Blanket for thermal Insulation Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

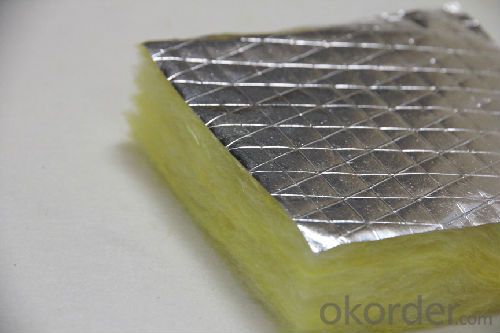

The glass wool Blanket with aluminum foil surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

- Q:What's the difference between the rock wool and glass wool board?

- Rock wool board is a kind of thermal insulation material that takes basalt or diabase as raw material and after processing into board, suitable for building exterior wall or roofing heat preservation, and it can also be used in the thermal insulation of large tanks, good strength, small water absorption, good thermal insulation properties, good machinability performance, superior fireproof?performance, the density can be up to 180 kg per cubic metre. Glass wool is made by taking silicon dioxide (glass) as raw materials and through processing, small density, light unit weight, thin fiber, little slag ball, good toughness and it can be bent randomly, and be processed into pipe, plate or blanket, etc., it's mainly used for heat preservation of light steel structure, overhead line (steam) or complex tanks, and it can also be used for the thermal insulation of steel set and steam pipe.

- Q:Are rubber and plastic thermal insulation material and glass wool in air conditioner energy-saving materials ?

- They are energy-saving materials.

- Q:how to get rid of the fur of the glass wool on the hand?

- Stick it out with tape medical tape, rheumatism paste tape, and scotch tape.

- Q:How to construct when apply rock wool board to glass curtain wall?

- Basic interface treatment: The wall should be cleaned off grease and floating ash, etc. The loose and weathering part should be removed. If the protrusions on the surface of the wall is greater than 10mm, it should be removed. In order to make the adhesion of the base interface unified and homogeneous, the wall needs interface processing. An injection gun or brush can be used to evenly coat mortar to ensure that all the walls have been treated. Before interface processing, bricks and aerated concrete walls needs watering to wet it. When blocking scaffold eyes and abandoned holes, first clean the debris, dust, etc. and then wet it, and then use cement and mortar at a proportion of 1: 3 to fill the holes tightly. 2, Suspend vertical line and the controlling line: The method of laying lines should be determined according to the height of the building. Using the theodolite to look for the verticality making use of corners of doors and both sides of windows. Stretch low carbon steel wire to find the rules, and the horizonal line can be controled crossly based on the 500mm lines as the datum line which is higher than the building. According to vertical flux lines and insulation thickness, flip the control line on both sides of the angles of each horizonal spacing between purlins, and then draw the horizonal flux line as the mark. 3, Installation of rock wool boards: (Box bonding method and achorage of expanded anchor bolts)

- Q:How many insulation supporting pins are there in one aquare meter of glass wool?

- 20 is enough

- Q:could experts tell me the producing method of insulating layer for glass?wool?board?

- Building looking for slope (from top to bottom) : Protective layer coating of SBS coiled material waterproof layer, a polyurethane waterproof coating film, 2 mm thickness, base treating agent, 30 mm or 40 mm, extrusion molding polyphenyl(EPS) board 20 mm, cement mortar, cement perlite thermal insulation mortar, the thinnest part is 50 mm, cast-in-place floor.

- Q:How many types of centrifugal glass wool?

- Glass wool belongs to a category of glass fibers, and it is a man-made mineral fibers. Glass wool is melten glass fibrosis, cotton-like material, and the chemical composition is metallic glass type, and is a inorganic fiber having good shape, bulk density, low thermal conductivity and thermal insulation and heat insulation, sound-absorbing properties, corrosion resistance and chemical stability.

- Q:Do you have any recommendation about the glue used to adhere the glass wool to glass?fiber felt? Thank you.

- You can try sodium silicate (sodium metasilicate) which is used to glue cartons.

- Q:Are there any hazards during the glass wool construction?

- Glass wool and asbestos are completely two different products. The raw material of glass wool is glass. Protection work must be prepared during construction.

- Q:What is the uses of aluminum foil glass wool felt?

- Glass wool serves as four fuctions to paste aluminum foil paper. Insulation, moistureproof, radiation protection, as well as decorative! Glass wool roll mat selection is based on three aspects. One: Dimensions, thickness of]glass wool roll mat of 50 mm, 75 mm, 80 mm, 90 mm, 100 mm, 120 mm. . Finally, it can be made as long as 200mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Wool For Oven

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 1000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords