Glass Wool Board 20kg/m3 china manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Glasswool Description

Glasswool board is the unearthly sound absorbing and warm keeping material. It has been widely applied for heat insulation of house wall, compartment; temperature keeping of computer rooms, refrigerator; denoise of power plants and pump rooms; adjustment of Hi-fi etc.

This special cell structure means that the sheet doe’s not conduct heat. When you lay XPS boards as an underlay any heat from your room or floor will be reflected back towards the floor surface. As you will not be wasting heat through your floor you will utilize your energy in an effective manner and thereby lower your energy consumption and carbon footprint.

2. Main Features

1. Excellent thermal insulation

2. High compressive strength of excellence

3. High-quality water-repellent, moisture resistance

4. Energy saving and environmental protection

5. Excellent heat preservation and insulation

3. Scope of application

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc

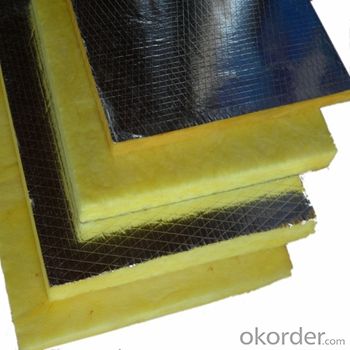

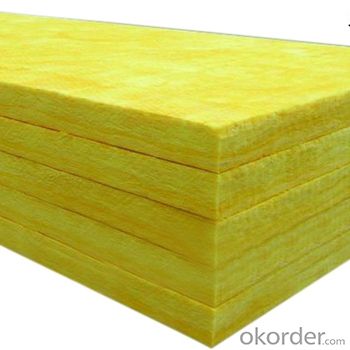

4. Glasswool Images

5. Glasswool Specification

density(kg/m3) | width(mm) | thickness(mm) | length(m) | packing/roll Vacuum package | |

10-48 | 1200 | 25-150 | 10-30m | 2roll | |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

6. FAQ

(1) How about your company?

A world class manufacturer & supplier of glasswool and is one of the large scale professional investment glasswool bases in China. Annually more than 1000 containers of glasswool are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

The user should take test and do trial application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q:What are the advantages and disadvantages of glass fiber insulation cotton?

- Since the biological effects of rock wool is similar with asbestos wool , but the severity of harm is much lower than the asbestos, and behavior, transfer, removal in the human body is similar with asbestos and carcinogenic mechanism is also similar. Fibrogenic and carcinogenic effects, must be accumulated as a sufficient number of fibers in the organization as a precondition. Therefore, the contact reduction is the fundamental measures to prevent the occupational hazard of asbestos supplement. Confined dust source: The main closed production machinery.

- Q:What are the advantages and disadvantages of centrifugal glass wool?

- Centrifugal glass wool board is fiber product, so human body will be allergic, whose temperature endurance is 400 degrees with good thermal insulation effect, mainly used in buildings and underground pipes.

- Q:what is the specification of glass wool sound-absorbing board?

- Mineral wool sound absorption board is mineral?wool?board, general specifications include 600*600,600*12000,300/400/500*1200-1800mm thickness is usually 14 to 22 mm. . But different production capacity depends on the specific manufacturer, the manufacturer without certain production capacity can't do the bar plate or reach the thickness. Here i recommend Meiluda mineral wool board, a factory with producing assembly line and ability. Cost performance was very good.

- Q:What is the density of high-temperature glass fiber

- Density 2.4 ~ 2.7g / cm3 Glass fiber is used as reinforced materials in reinforcing plastic. the biggest feature is strong tensile strength. standard tensile strength is 6.3 ~ 6.9 g / d,in a wet state 5.4 ~ 5.8 g / d. Density 2.54. Good heat resistance. the tensile strength remains unchanged even if the temperature reaches as high as 300℃. It is high duty electrical insulation material. It is also used for thermal insulating and fireproof. it is only corroded by concentrated?alkaline,hydrofluoric?acid and concentrated phosphoric?acid.

- Q:What is the difference between red glass wool and yellow glass wool in terms of technical parameters?

- The majority of glass wools are yellow, while glass wools with the color of red or other are called color glass wool which are rarely used.

- Q:What kinds of thermal insulation method do the Insulation glass wool insulation materials belong to?

- Glass wool insulation materials are medium and low temperature thermal insulation materials, thus they are generally used in civil and cryogenic pipeline.

- Q:What is the heat conductivity coefficient of glass wool ?

- Glass wool has high thermal conductivity. The higher the thermal resistance of thermal paste, the poorer the heat-conducting property. Good domestic thermal pastes are Balance Stars DRG series, STARS series from 0.65-3.8W / m-k. Good international brands are Shin-Etsu, DowCorning, Laird and so on. Thermal conducting silica?gel and silicone?grease belong to thermal interface materials. Thermal conducting silica gel is thermal conductive RTV adhesive, a kind of pouring sealant which can be cured at room temperature. The biggest difference between heat conductive silicone?grease and silica?gel is that heat conductive silica?gel can be cured and has a certain bonding property. Thermal conductive silicone?grease is a kind of material used to fill the gap between CPU and cooling fin.

- Q:What are the features of glass wool decorative acoustic?panel?absorber suspended ceiling?

- 1, Excellent decorative effect. Mineral wool acoustic board has various patterns and reliefs, stereoscopic model, reflecting ancient glory and modern fashion, really refreshing. 2. good thermal insulation property. Mineral wool acoustic board is good thermal insulation material which can be make the house warm in winter and cool in summer and save energy for users because it has low heat conductivity coefficient. 3. sound absorption and noise reduction. The main raw material of mineral wool acoustic board is ultra-fine mineral wool fibre whose density is about 200 ~ 450Kg / m, so it has many perforative micropores which can effectively absorb sound waves and reduce sound wave reflection so as to improve indoor tone quality and reduce noise. 4. fireproof. Since the mineral wool is an inorganic material, it will not burn, and mineral wool acoustic board has very low content of organics, thus making it meeting requirements of Class B1 non-combustible. And our products have been able to reach non-combustible Class A . 5. Green and eco-friendly, regulating air. Mineral wool acoustic board does not contain harmful substances. It contains active groups which can absorb harmful gases in the air and its porous structure can absorb and release water molecules so as to purify the air and adjust indoor air humidity . 6. moisture-proof and insulation. Since mineral wool acoustic board contains a large number of micropores and has releatively large surface area, it can absorb and release water molecules in the air and regulate indoor air humidity. It can be regarded as a decorative board that can breath.

- Q:Specifications and models of glass wool

- Models of glass wool: 32kg / 50mm, 48kg / 50mm, 80kg / 50mm, 96kg / 25mm, 80kg / 25mm

- Q:These two kinds of glass wool are used as insulation materials, but one keeps 0.3 in specific gravity while the other keeps 0.5 in specific gravity. Which one should be chosen?

- Specific gravity has much to do with quality and thermal conductivity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Wool Board 20kg/m3 china manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords