Glass Steel Centrifugal Pumps Model FS Glass Steel Centrifugal Pumps

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction & Features:

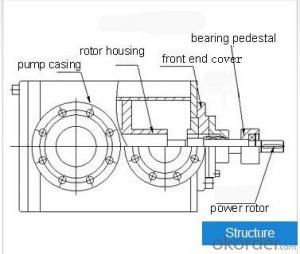

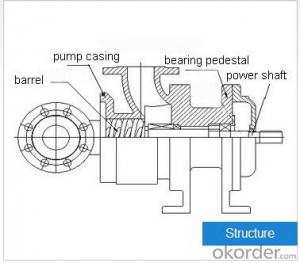

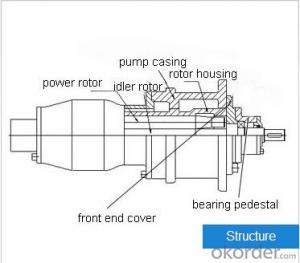

Glass Steel Centrifugal Pumps Model FS, its contact with the liquid flow components are made of polyvinyl butyral modified phenolic glass fiber material molded from high temperatures, has good corrosion resistance, high temperature resistance, light weight, high specific strength, no deformation. Seal with common type and resistant species of particle type machine inside cover reasonable structure, consume less power.

Seal: WB2 externally mounted F4 bellows mechanical seal, reliable sealing, reliable sealing, use a long time.

Transmission and direction of rotation of the pump: pump through the claw-type flexible coupling, directly driven by the electric motor, the rotation on the pump from the motor side is clockwise.

Glass Steel Centrifugal Pumps Model FS range

Applications:

The pump is mainly used in petrochemical, metallurgy, dyes, printing and dyeing, pesticides, pharmaceuticals, rare earth, leather and other industries, delivery of solid particles, easy crystallization temperature no higher than 100 ℃ for various non-oxidizing acid (hydrochloric acid, sulfuric acid formic acid, acetic acid, butyric acid) and other corrosive media essential ideal equipment.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Steel Centrifugal Pumps Model FS Glass Steel Centrifugal Pumps

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords