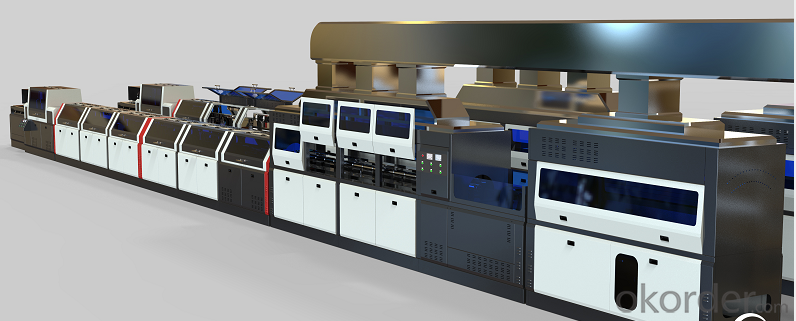

Glass reinforced plastic anchor rod production equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

- Option:

- MYC-1200

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

My company research and development, production and sales have all threaded glass reinforced plastic anchor rod production line of the world's leading standard.

The length of the line at home and abroad and its own unique technology, has many characteristics, such as advanced technology, reliable performance.

This production line is mainly advantages: high efficiency (1000-1500 - mm/min, are two to three times of general equipment); To save the cost of materials (10-30%) can decrease; Cost saving process (1-3 yuan/m); High automation easy operation (4) / 2 production line; Environmentally friendly low energy consumption.

Company can match for different clients, all kinds of nuts and tray processing equipment (including high strength non-metallic nut, the bearing capacity of the pallet 150 kn) or higher.

Company can also offer to the customer required to produce a series of special resin, curing agent and other raw materials, price is superior.

Glass rod equipment and product advantages:

A, a molding: pole, mother

Second, the speed: 1.2 meters per minute

Three, large torque, more than 50-130 according to customer's need

Four, carrying big: tray, the self-contained mother is our patent products

Five long, continuous production time: 36 hours

Six, low cost, lower 1-2 yuan per meter

Seven, provide raw materials: sell cheap

Eight, formulation science, reasonable of tesco

Nine, life-long service: repair and simple

10, a variety of cooperation: a win-win purpose * thick jersey cargo

To make science and technology into productivity, to make glass reinforced plastic anchor rod in coal, building and other fields used widely as soon as possible: sincerely welcome industry peers to company guidance, hit new high together!

Sincerely welcome clients to visit our company guidance, win-win premise to seek common development!

- Q:Is the management of chemical plants harmful to the body

- According to the nature of the work: 2, 3, 4, 5, 7 of the above work items may cause injury or occupational health hazard to the equipment manager, especially the direct contact. (1) for item 2, the detection process may be exposed to radioactive ionizing radiation, chemical cleaning before driving, and the damage of the scavenging process (2) for item 3, the maintenance of the site may be exposed to dangerous chemicals, hot surfaces, mechanical injuries, falls, and objects (3) on the fourth term, the same; But it may be exposed to residual hazardous chemicals, high pressure and high temperature in equipment and pipelines (4) for the fifth term, and the fourth term, there is a radioactive hazard to the use of gamma rays (5) to item 7, pressure vessels (and accessories, such as safety valve, rupture disk), pressure pipes, elevators, elevator, forklift, crane, may come into contact with the residual of dangerous chemicals, falling objects, and the harm of high pressure In a nutshell, chemical enterprise of equipment maintenance management, especially the first line maintenance (overhaul or instrument), in the factory is the highest population in the occupational hazards and occupational disease hazards.

- Q:How to handle the chemical hazardous material production license?

- In accordance with the provisions of the local safety department, approved by the local municipal people's governments for examination and approval go through the formalities for examination and approval of hazardous chemicals production enterprise new set up after, and then to three after at the same time, provide relevant information to the local work safety department, apply for to deal with hazardous chemicals production license.

- Q:What are the characteristics of chemical equipment

- (1) adapt to the performance, quantity, technological characteristics and scale of production of materials, products, intermediate products, etc. (2) a set of production equipment, regardless of the continuous and intermittent production, are composed of a variety of multiple devices, therefore requires chemical equipment between each other and with other equipment, equipment and pipelines, valves, instruments, meters, electric circuit and so on to have reliable between collaborative and suitability;

- Q:What type of anticorrosive paint for chemical equipment pipeline

- Yue SR201 first underwater heavy-duty coating is a kind of high performance and double packing type heavy anti-corrosion products of environmental protection, to satisfy the people to the ocean engineering and ship as well as the requirements of modern industrial anti-corrosion coatings. It is using a new type of polymer materials as corrosion inhibitors and new developed a highly efficient heavy-duty coating, can be generated in the metal surface layer close to the metal surface, Fe2O3 with protective film, the metal in the passivation state, dense and low porosity of the film make alkaline metal surface, prevents the antioxidant through reach the surface of the metal film corrosion reaction, so as to truly solve the underwater long-term anti-corrosion technology difficult problem.

- Q:There are chemical products for machining

- Popular said, mechanical processing is according to the drawings design requires the use of machinery and equipment. Through forging cutting. Extrusion method changes the shape of the blank workpiece. Such as size, surface quality, etc. The machine of forging, cutting, milling, planing, grinding, etc. Common or numerical control machine tools, and the specialized machine tools for processing large quantities of products.

- Q:What kind of packing bags do you need?

- You say these bags already have a production machine.

- Q:The chemical plant is used mechanically

- What kind of plants do you see in the heat exchanger and the air cooler

- Q:Which equipment should be classified into the main equipment in chemical production?

- If the device has a problem, it will affect the device's manufacturing or safety equipment.

- Q:Why is the volume of the chemical plant bulky

- It's not always huge, and there's always a small volume of equipment for fine chemicals. If the factory USES a large volume of equipment, it means that the factory has this need -- operating income = unit sales volume, so a lot of times scale brings benefits

- Q:What kind of production equipment do petrochemical industry use,

- Petrochemical production equipment, pump, blower, mixer, compressor, piping, heat exchanger, air cooling, columns, valves, boilers, motors, power distribution cabinet, transformer, instrument, etc

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass reinforced plastic anchor rod production equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

- Option:

- MYC-1200

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords