Glass Fiber E-glass Emulsion Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber E-glass Emulsion Chopped Strand Mat

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

1. Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2. Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3. Excellent flexibility ensures good mold ability with no spring back at sharp angles.

4. Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhances productivity and mechanical properties of the end products.

5. The composite products have high dry and wet tensile strength and good transparency.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

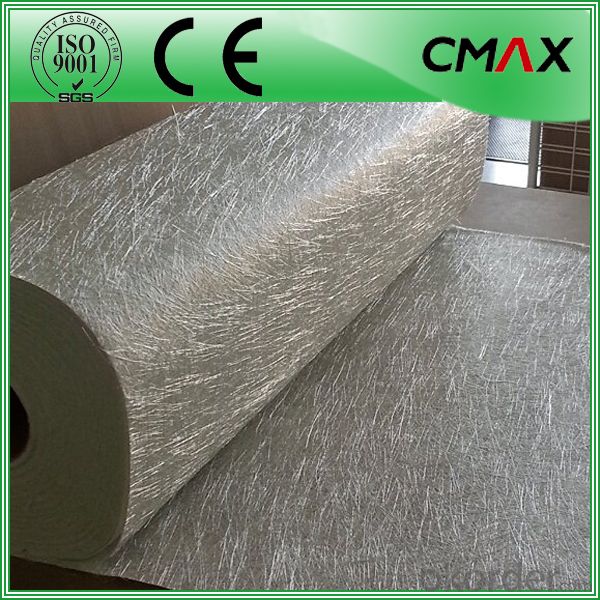

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q:What is the typical thickness of fiberglass facing?

- The typical thickness of fiberglass facing ranges from 0.2 to 1.0 millimeters.

- Q:Are there any health concerns associated with fiberglass facing?

- Fiberglass facing presents health concerns that one should be aware of. The composition of fiberglass consists of minuscule fibers that can become airborne if disturbed, such as during installation or removal. Inhaling these fibers can cause irritation to the respiratory system and result in symptoms like coughing, tightness in the chest, and difficulty breathing. Furthermore, prolonged exposure to fiberglass fibers can lead to fibrosis, a severe lung condition characterized by scarring and stiffness in the lung tissues. Moreover, direct contact with fiberglass can cause skin irritation and trigger allergic reactions. The tiny fibers are capable of penetrating the skin, leading to itchiness, redness, and the development of a rash. To minimize the associated health risks, it is crucial to take precautions when working with fiberglass. This involves wearing appropriate protective clothing, gloves, goggles, and a respirator to prevent the inhalation of fibers. Additionally, it is essential to properly clean up any fiberglass dust or debris to avoid further exposure. If there is a suspicion of fiberglass exposure and persistent respiratory or skin symptoms are experienced, it is strongly recommended to seek medical attention for a thorough evaluation and appropriate treatment.

- Q:How is fiberglass facing installed?

- Fiberglass facing is typically installed by positioning it against the desired surface and securing it with adhesive or mechanical fasteners such as staples or screws. The facing is then smoothed out to remove any wrinkles or air bubbles, ensuring a tight and even installation.

- Q:How is fiberglass facing used in construction?

- Fiberglass facing is commonly used in construction as a protective layer for insulation materials. It is typically applied to the exterior side of insulation boards or blankets. The facing is made of woven fiberglass fabric or reinforced foil, which adds strength and durability to the insulation. One of the main purposes of fiberglass facing in construction is to act as a vapor barrier. It prevents the passage of moisture through the insulation, reducing the risk of condensation and mold growth. By keeping the insulation dry, it maintains its thermal performance and extends its lifespan. Additionally, fiberglass facing also serves as a radiant barrier. It reflects radiant heat, helping to minimize heat transfer between the environment and the insulation. This property is particularly beneficial in hot climates or when insulating buildings that are exposed to direct sunlight. Moreover, fiberglass facing enhances the mechanical properties of insulation materials. It provides structural support and protection against damage during handling, transportation, and installation. It also improves the fire resistance of the insulation system by acting as a barrier to flames and reducing the spread of fire. In summary, fiberglass facing is a versatile component used in construction to enhance the performance and durability of insulation materials. It acts as a vapor barrier, radiant barrier, and protective layer, ensuring that buildings are well-insulated, energy-efficient, and safe.

- Q:How does fiberglass facing contribute to energy efficiency in buildings?

- Fiberglass facing contributes to energy efficiency in buildings by acting as a thermal insulator. It helps to reduce heat transfer through the walls, ceilings, and floors of a building, leading to improved energy conservation and lower utility bills. Additionally, fiberglass facing can also provide an effective barrier against air infiltration, reducing drafts and improving indoor air quality.

- Q:Roof waterproof general use of what materials

- 1. EPDM rubber waterproofing membrane: cold sticky or self-adhesive method. 2. Chlorinated polyethylene waterproofing membrane: cold sticky method. 3. PVC waterproofing membrane: cold sticky method. 4. Chlorinated polyethylene - rubber blend waterproofing membrane: cold sticky method. 5. EPDM - polyethylene blend waterproofing membrane: cold sticky method. 6. Polyurethane waterproof coating: reactive cold construction. 7. Acrylic waterproof coating: cold construction, can be scraping, can be, can be sprayed, but the construction temperature needs to be higher than 4 ℃ when the film.

- Q:How does fiberglass facing improve insulation?

- Fiberglass facing improves insulation by providing an additional layer of protection to the insulation material. The facing acts as a barrier, preventing air and moisture from entering or escaping the insulation. This helps to maintain the desired temperature inside the insulated space, as well as preventing the growth of mold or mildew. Additionally, the facing enhances the durability and strength of the insulation, making it more resistant to damage and ensuring its longevity. It also enhances the fire resistance of the insulation, providing an added layer of safety. Overall, the fiberglass facing improves insulation by enhancing its thermal performance, moisture resistance, durability, and safety.

- Q:China's glass fiber product code is what?

- P, S used in polyester hand paste molding, X used in epoxy laminating;

- Q:Is fiberglass facing resistant to moisture or water damage?

- Fiberglass facing, indeed, possesses remarkable resistance against moisture and water damage. This exceptional property arises from the composition of fine glass fibers interwoven to form a robust and enduring material. Absent any capacity to absorb moisture, these fibers bestow upon fiberglass facing a high degree of resilience, rendering it especially suitable for environments prone to water or moisture exposure, like bathrooms, kitchens, and outdoor spaces. Moreover, its resistance to mold and mildew growth further heightens its ability to endure moisture.

- Q:What is the glass fiber needle felt dust filter bag

- The fibrous web is reinforced by a felt-like nonwoven fabric filter material. Hangzhou Xiao Yang, yes

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Fiber E-glass Emulsion Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords