Gibbsite Bauxite,Bauxite 85,Calcined Bauxite 88 From China !!!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Details: | In 25KG bags;1MT/1.25MT/1.35MT bags or as your requirements. |

| Delivery Detail: | 15-30 days after contract |

Product Description

| Items | Al2O3 | Fe2O3 | B.D. | K2O+Na2O | CaO+Mgo | TiO2 |

| 88 | 88%min | 1.5%max | 3.25min | 0.25%max | 0.4%max | 3.8%max |

| 87 | 87%min | 1.6%max | 3.20min | 0.25%max | 0.4%max | 3.8%max |

| 86 | 86%min | 1.8%max | 3.15min | 0.3%max | 0.5%max | 4%max |

| 85 | 85%min | 2.0%max | 3.10min | 0.3%max | 0.5%max | 4%max |

| 83 | 83%min | 2.0%max | 3.05min | 0.3%max | 0.5%max | 4%max |

| 80 | 80%min | 2.0%max | 3.0min | 0.3%max | 0.5%max | 4%max |

| 78 | 75-78% | 2.0%max | 2.8-2.9 | 0.3%max | 0.5%max | 4%max |

Size: 0-1mm,1-3mm,3-5mm,5-8mm,8-10mm,200mesh,325mesh or as your request.

Application

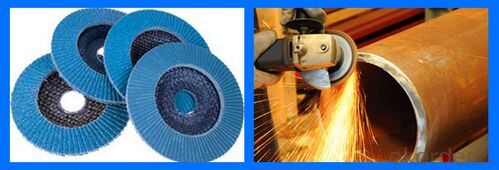

mainly used in aluminium metallurgy,aiso used in abrasive ,cement ,chemical, refractory

- Q:What is cokeWhat applications are, what is the fire of Malachite copper

- Malachite is a kind of copper, copper smelting with coke burning malachite is under high temperature.

- Q:What is the amount of waste gas produced by a ton of coke burning

- Process for producing coke, coke oven gas and coking chemical products by thermal decomposition and coking.

- Q:What are the indicators of first grade coke and the two grade coke?

- The mechanical strength of the mechanical strength of ash sulfur%% volatile(crush strength M40) (abrasion strength M10)

- Q:The chemical composition of coke is m10.m25

- Different uses of different coke porosity index requirements, the general requirements of metallurgical coke porosity in the 40 ~ 45%, 35 ~ 40% in coke, coke export demand is about 30%. The crack and porosity of coke and coking coal for the level, which has a direct relationship, such as coal based coke refining cracks, porosity, high strength, low; with coal as the foundation of the coal refining coke crack less, low porosity and high strength. The strength of coke is used to denote the crushing strength and abrasion resistance of the two indicators.

- Q:What is the use of coke

- From the distribution of coke production in China, the distribution of coking enterprises in China is unbalanced, which is mainly distributed in North China, East China and northeast china. Three, the use of coke coke is mainly used in blast furnace ironmaking and copper, lead, zinc, titanium, antimony, mercury and other non-ferrous metal smelting furnace, reducing agent, heating agent and the role of the material column skeleton. The use of coke instead of charcoal in the blast furnace has laid the foundation for the large-scale development of modern blast furnaces and is a major milestone in the history of metallurgy. In order to achieve better technical and economic indexes of blast furnace operation, the coke (metallurgical coke) must have proper chemical and physical properties. In addition to a large number of coke used in iron smelting and non-ferrous metal smelting (metallurgical coke), but also for casting, chemical, calcium carbide and iron alloy, the quality requirements are different. Such as foundry coke, generally require large size, low porosity, high fixed carbon and low sulfur; chemical gasification, strict requirements for strength, but requires good response, high ash melting point; calcium carbide and coke production requirements to improve the fixed carbon content.

- Q:What are the criteria for coke classification and how to distinguish between primary and two grade coke?

- Evaluation of coke quality1, sulfur content in coke: sulfur is a harmful impurity of iron smelting, which reduce the quality of pig iron. In the steel-making pig iron sulfur content greater than 0.07% is waste. By blast furnace furnace into sulfur from 11% ore; 3.5% from limestone; 82.5% from coke, so coke is the main source of sulfur in charge coke. Sulfur directly affects the production of blast furnace coke. When the sulfur content is greater than 1.6%, sulfur increased 0.1%, the amount of coke increased 1.8%, limestone amount increased 3.7%, 0.3% increase in amount of ore blast furnace output to reduce the sulfur content under 1.5 - 2.0%. metallurgical coke is not greater than 1%, the sulfur content of large and medium-sized metallurgical coke the blast furnace is less than 0.4 - 0.7%.2, the phosphorus in the coke: iron metallurgical coke coke content should be in the 0.02 - 0.03% or less

- Q:What is the sample quantity of coke moisture test? What is the test time? How many degrees? That is the national standard.

- Three, instrument and equipment of drying box: with automatic temperature adjusting device, can maintain the temperature of 170 DEG C and 105 a 180 a 110 C, the tray is made from galvanized sheet iron or aluminium sheet, size is about 300mm x 200mm X 20mm. The glass weighing bottles: diameter 40mm, high 25mm, and a grinding cover tightly. Dryer: inside the color of silica gel or granular anhydrous calcium chloride

- Q:Why does Coke provide heat when it is fired, it reacts only at high temperatures and why it is needed to provide heat?Which is the exothermic reaction, carbon dioxide or carbon monoxide?

- Yes;To restore the Fe reaction to provide heat, this reaction requires a higher heat, but the heat is high, the heat is not high enough to provide; so adding coke, more convenient to raise the temperature;

- Q:Why in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produceWhy in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produce

- The role of coke in the blast furnace: 1 reducing agent 2 heating agent 3 skeleton role. Combined with the effect of coke in the blast furnace can know compared with coke instead of charcoal. The coke oven gas is produced high calorific value of fuel, and is an important raw material for organic synthesis industry.

- Q:Can the sulfur content of coke affect the casting process of nodular cast iron at 0.65?

- The high sulfur content of nodular cast iron, the most significant impact on the casting is caused by poor balling,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gibbsite Bauxite,Bauxite 85,Calcined Bauxite 88 From China !!!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products