Geotextile Road Used Polypropylene Nonwoven Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

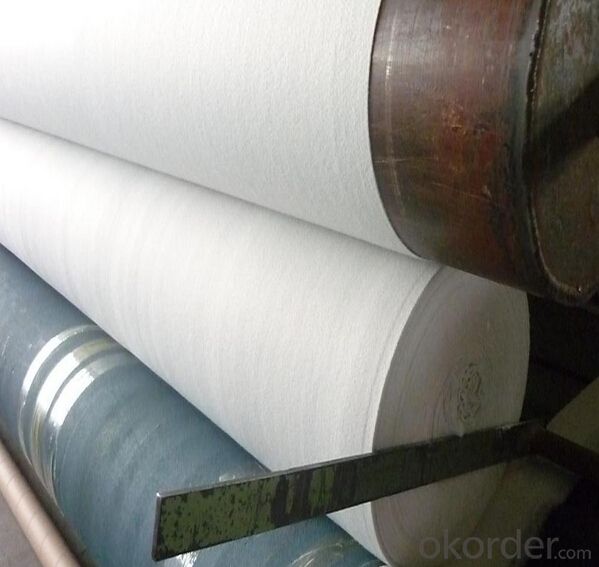

Geotextile Road Used Polypropylene Nonwoven Geotextile

Desciriptions:

Geotextile Road Used Polypropylene Nonwoven Geotextile are the preferred products for lining projects requiring low permeability , corrosion protection ,exceptional chemical and ultraviolet resistance properties ,which makes them extremely cost effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:How do geotextiles help with weed control in landscaping projects?

- Geotextiles aid in weed control in landscaping projects by acting as a barrier between the soil and the weed seeds. These permeable fabrics allow water and air to pass through, ensuring proper drainage and maintaining soil health, while preventing weed growth by blocking sunlight and impeding weed seed germination.

- Q:What are the benefits of using geotextiles in construction projects?

- Geotextiles offer several benefits in construction projects. Firstly, they provide effective erosion control by stabilizing soil and preventing sediment movement, helping to maintain the integrity of embankments and slopes. Additionally, geotextiles act as a barrier against weed growth, minimizing maintenance efforts. They also enhance drainage and filtration systems, improving the overall performance of infrastructure projects. Furthermore, geotextiles can be used as reinforcement materials, providing strength and stability to various construction components like roads, retaining walls, and foundations. Overall, the use of geotextiles in construction projects offers cost-effective and environmentally friendly solutions for a range of engineering challenges.

- Q:How do geotextiles contribute to slope stability analysis?

- Geotextiles play a crucial role in slope stability analysis by providing reinforcement and soil stabilization. They are often used to improve the internal strength and mechanical properties of soils, preventing erosion and maintaining slope integrity. Geotextiles act as a barrier, distributing loads and reducing the potential for soil movement. Their high tensile strength helps in reinforcing slopes and retaining walls, increasing overall stability and reducing the risk of slope failure.

- Q:What are the considerations for geotextile selection in shoreline erosion control?

- When selecting geotextiles for shoreline erosion control, several considerations need to be taken into account. These include the strength and durability of the geotextile, its resistance to UV degradation and chemical exposure, its permeability to allow for proper drainage, and its ability to retain sediment while still allowing for plant growth. Additionally, factors such as cost-effectiveness, installation requirements, and the specific environmental conditions of the shoreline should also be considered in the selection process.

- Q:Can geotextiles be used in railway track construction?

- Yes, geotextiles can be used in railway track construction. Geotextiles provide various benefits such as soil stabilization, drainage, filtration, and separation. They can be used to improve the performance and longevity of railway tracks by providing reinforcement, preventing soil erosion, and reducing maintenance requirements.

- Q:Can geotextiles be used in the protection of bridge abutments?

- Yes, geotextiles can be used in the protection of bridge abutments. Geotextiles are commonly used in civil engineering projects to provide erosion control, soil stabilization, and drainage. In the case of bridge abutments, geotextiles can be employed to prevent soil erosion, reduce water infiltration, and enhance the overall stability of the structure. By acting as a barrier, geotextiles can help protect the abutments from the damaging effects of water and soil movement, increasing the lifespan and durability of the bridge.

- Q:Can the roof waterproof with geotextiles?

- It is generally believed that the individual geotextile does not have the anti-seepage effect, the main assessment index is the permeability coefficient, the general geotextile coefficient is higher than the ordinary soil, about 0.01-0.001 look, but geotextiles and rubber, Asphalt, plastic will form a combination of impermeable composite, anti-seepage effect increased by 10 times, and asphalt, rubber combined into a waterproof

- Q:How do geotextiles affect soil properties?

- Geotextiles can have a positive impact on soil properties by improving its stability, filtration, and drainage capabilities. These synthetic fabrics act as a barrier, preventing soil erosion and promoting soil compaction. Additionally, geotextiles can enhance the soil's ability to retain water, aiding in irrigation and reducing the risk of drought.

- Q:Highway road crest u block below the geotextile roadway below the curb

- The use of steel template investment is too large, do not return the cost of the use of plastic template, the summer comes, will be the deformation of the current use of a curb stone molding machinery, prefabricated ratio can guarantee the strength of the mold release time, Segregation of water content, the mortar will stick mold, in short, the appearance of substandard match ratio can guarantee the strength, and this is only one aspect, you now encounter is the operability of concrete problems, but also in the mix of experimental templates The problem of stiffness is to ensure that the key to forming the surface of the finish problem is one of the factors, there is the effect of concrete vibrating and quality, concrete demolition of the time and so on. Addition agent, the rational use of release agent can be considered an auxiliary means

- Q:What are the specifications for geotextiles in sediment control projects?

- The specifications for geotextiles in sediment control projects typically include factors such as the material type, weight, permeability, and strength. They should be made of durable materials that can withstand environmental conditions and retain sediment effectively. The weight of the geotextile is usually specified to ensure proper retention of sediment particles. Permeability is an important factor as it allows water to pass through while retaining sediment. Lastly, the strength of the geotextile should be sufficient to withstand installation and potential stress from soil erosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geotextile Road Used Polypropylene Nonwoven Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords