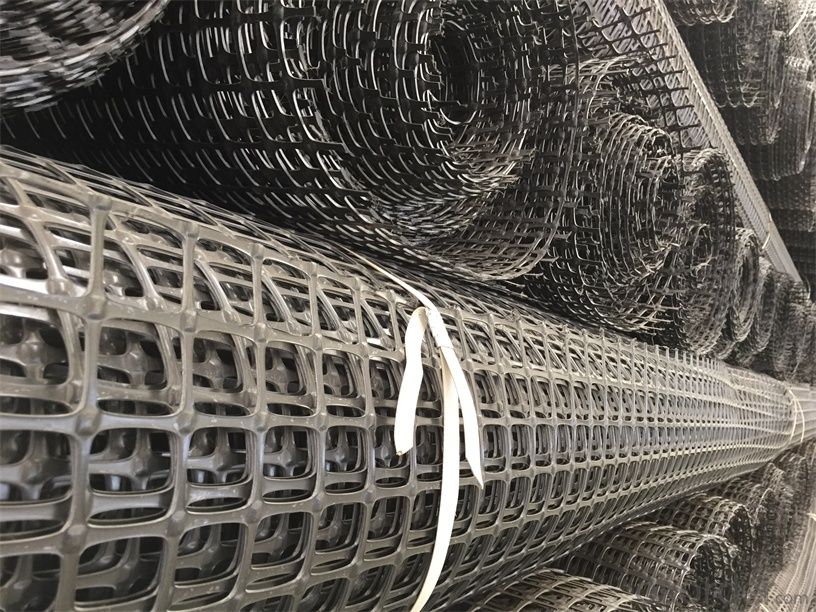

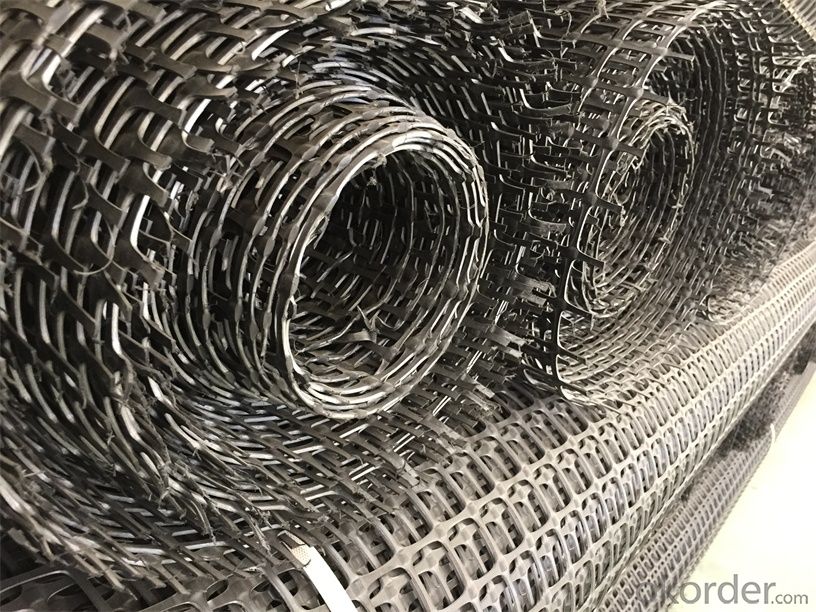

Geogrid with High Tensile Strength Warp Knitted

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q:Can geogrids be used in retaining walls for waterfront parks?

- Yes, geogrids can be used in retaining walls for waterfront parks. Geogrids are commonly used in retaining wall construction as they provide reinforcement and stability to the soil. In the case of waterfront parks, where the retaining walls are exposed to water and potential erosion, geogrids can help prevent soil movement, maintain the integrity of the wall, and enhance its overall durability.

- Q:How to determine the number of geogrid detection method

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.3) fill: after the completion of the grille, should be timely (48 hours) filling. Each layer should be carried out according to the principle of "the first two sides, the middle of the back". The packing is not allowed to be unloaded directly on the geogrid. It must be unloaded on the soil surface which has been paved. The soil unloading height is not more than 1m. All vehicles and construction machinery shall not be allowed to walk directly on the paved geogrid, but only to be allowed to travel along the axis of the embankment.4) the upper and lower sides of the geogrid, and 8 cm from the grid layer shall not be more than 6 cm in diameter.

- Q:Can geogrids be used in retaining walls for highway projects?

- Yes, geogrids can be used in retaining walls for highway projects. Geogrids are commonly used in such projects to reinforce soil and provide stability to the retaining walls. They enhance the overall strength and durability of the walls, making them a reliable choice for highway construction.

- Q:What are the load-bearing capacities of geogrids?

- The load-bearing capacities of geogrids vary depending on factors such as the type and quality of the geogrid, the soil conditions, and the specific application. Geogrid manufacturers typically provide technical data sheets specifying the load-bearing capacities of their products, which can range from a few kilonewtons to several hundred kilonewtons per meter. It is important to consult these specifications and conduct appropriate engineering analysis to determine the suitable geogrid and its load-bearing capacity for a particular project.

- Q:What are the design considerations for geogrid-reinforced embankments?

- Some design considerations for geogrid-reinforced embankments include selecting the appropriate geogrid materials and properties based on the soil conditions, determining the required geogrid strength and stiffness, ensuring proper installation and connection of the geogrid, considering the potential for differential settlements, evaluating the long-term performance and durability of the geogrid, and considering the overall stability and safety of the embankment structure.

- Q:Can geogrids be installed on steep slopes?

- Yes, geogrids can be installed on steep slopes. Geogrids are commonly used in the construction industry to reinforce soil and provide stability on slopes. They are designed to withstand high tensile forces and can effectively reinforce the soil, preventing erosion and slope failure even on steep slopes.

- Q:The difference between geocell and geogrid

- The geocell is a kind of three-dimensional grid chamber structure, which is formed by the high strength welding of the HDPE material. Generally welded by ultrasonic needle. Due to the need of the project, some of them are punched on the diaphragm.

- Q:Are geogrids suitable for reinforcement of steep slopes?

- Yes, geogrids are suitable for reinforcement of steep slopes. Geogrids provide stability and reinforcement to the soil, preventing erosion and slope failure. They are designed to distribute the load and increase the strength of the soil, making them an effective solution for reinforcing steep slopes.

- Q:What is the effect of installation damage on geogrid performance in long-term applications?

- Installation damage can have a significant negative effect on geogrid performance in long-term applications. Damage during installation, such as stretching, tearing, or misalignment of the geogrid, can weaken its structural integrity and compromise its ability to effectively reinforce the soil. This can result in reduced load-bearing capacity, decreased soil stabilization, and overall diminished performance of the geogrid over time. It is crucial to ensure proper installation techniques and minimize damage to preserve the long-term effectiveness of the geogrid.

- Q:Glass steel grille is how to produce

- Production process of FRP grid:Preparation of mold - Preparation of mixed resin - glass fiber yarn - (or at the same time) pouring resin and exhaust bubble - mold heating, product curing - mold - finishing - Inspection packaging.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geogrid with High Tensile Strength Warp Knitted

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords