General Purpose Pumping LYB vertical arc gear pump oil pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: Vertical Installed Pump for Ship

Characteristic: It has characteristics low noise, long life and high efficiency.

Shaft seal: This series of pump adopt mechanical sealing. It also adopts the packing seal according to the requirement of customer.

Temperature: The max environment temperature is 50 °C and the max use temperature is 80 °C.

( If you are looking for arc gear pump used in ships, just need it -- LYB Vertical Arc Gear Pump. )

| Name | Value |

| Brand | China |

| Type | LYB arc gear pump |

| Model | LYB VERTICAL ARC GEAR PUMP |

| Temperature | Environmental temperature: <50°c Use temperature: <80°c |

| Viscosity | 5~1500cSt |

| Rated pressure | 0.6Mpa |

| Frequency | 50Hz 60Hz |

| Certification | GL, ABS, BV, CE, CNV etc. |

| Deliever time | About 25~40 days according to quantity. |

More Details:

| MOQ | 1 SET |

| Certification | GL, ABS,BV, CE, 3C, ISO9001-2000, GJB9001A-2001 |

| Package | Standard export carton or plywood case. (By sea or by air) |

| Deliver date | Within 25 working days after confirm orther |

| Warranty | 1 year |

| Customized | Available |

LYB arc gear pump

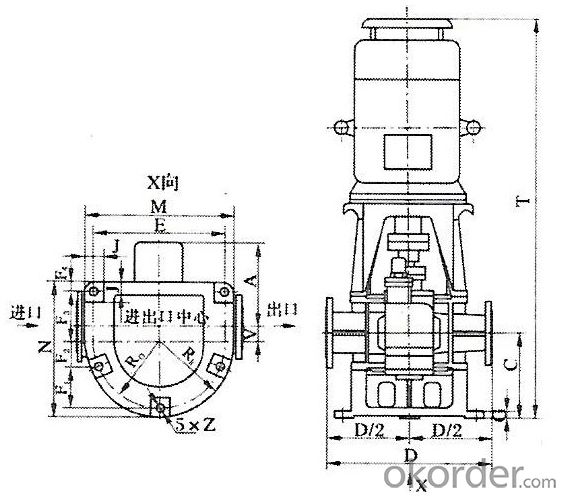

Outline and Installation diagram

Performance parameter

Rated pressure: 0.6Mpa

| Model | Diameter | Rated Capacity(m3/h) | |||

| Inlet*Outlet | 60Hz | 50Hz | |||

| 1180rpm | 900rpm | 970rpm | 720rpm | ||

| LYB20 | Φ100*Φ80 | 24 | - | 20 | - |

| LYB25 | 30 | - | 25 | - | |

| LYB30 | Φ125*Φ100 | 36 | - | 30 | - |

| LYB40 | Φ150*Φ125 | 48 | - | 40 | - |

| LYB50 | Φ150*Φ125 | 61 | - | 50 | - |

| LYB65 | - | 65 | - | 55 | |

| LYB80 | - | 80 | - | 65 | |

| LYB90 | - | 90 | - | 75 | |

| LYB100 | Φ200*Φ150 | - | 100 | - | 85 |

| LYB150 | - | 150 | - | 125 | |

| LYB175 | Φ250*Φ200 | - | 175 | - | 145 |

| LYB200 | - | 200 | - | 165 | |

All Products can be matched with different motors as customer's requirment

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

- Q:Is the diaphragm pump and the drain pump one?

- Therefore, the need to play a liquid discharge pump, if the medium is corrosive liquid, high viscosity, volatile, flammable, highly toxic liquid, you can choose diaphragm pump. Conversely, the general liquid, there is no special requirements, you can use the general centrifugal pump to reduce costs.

- Q:What is a solution pump?

- Principle and structure features of canned motor pumpThe ordinary centrifugal pump is driven by coupling the pump impeller shaft is connected with the motor shaft, the impeller and the motor rotates while working and shielding pump is a kind of non seal pumps, pump and motor is sealed in a medium filled by pumping the pressure vessel, the pressure vessel only static seal and, by a group of wires to provide a rotating magnetic field and drive the rotor. This structure eliminated the traditional centrifugal pump with a rotary shaft sealing device, it can do no leakage.The pump and motor pump together, motor rotor and pump impeller fixed on the same shaft, use of shielding the rotor and the stator of the motor rotor separated in the medium, its power is transferred to the rotor through the stator magnetic field.

- Q:Does the control cabinet of the fire control pump need to be related to the fire control room?

- The relationship is simple, the fire pump is pressurized water supply device, the control cabinet is the power supply for the fire pump, the regulator tank is to stabilize the pressure of the network management, reduce the pump frequently start device.

- Q:What is the "variable" of a variable pump? Is the displacement change or the flow change? Thank you

- There are many ways to change the variable pump flow: by changing the eccentricity to change the piston stroke length (radial piston pump, the frequency change principle) motor speed to adjust the flow (such as gear pump flow control principle).

- Q:How does the centrifugal pump pump and cut the pump?

- Check the motor, pump and fasteners in good condition; whether the lubricant is added or not;Disc dynamic coupling, whether or not stuck phenomenon;Open the inlet valve, remove the gas in the pump or pump the gas out of the pump;

- Q:The working principle of magnetic pump

- Structure characteristics1. permanent magnetPermanent magnet operating temperature range is made of rare earth permanent magnet wide (-45 - 400 DEG C), high coercivity, magnetic anisotropy direction is very good, also won't happen in the same demagnetization phenomenon when is close, is a good source of the magnetic field.2. isolation sleeveIn the metal isolation, isolation sets in a sinusoidal alternating magnetic field, in a cross section perpendicular to the direction of magnetic field lines induced eddy current and converted into heat. Eddy current expression is:. The Pe - K constant; eddy current; rated speed of N - T - pump; magnetic drive torque; F - the pressure inside the sleeve; D sleeve diameter; a material resistivity; and the tensile strength. When the pump design is completed, N, T is the given conditions, to reduce eddy current only from F, D, and so on. Non metallic materials with high resistivity and high strength production isolation, in reducing the eddy current effect is very obvious.

- Q:Please give me professionals to calculate, the cylinder bore is 100 and the rate of 20m/s, the leakage can be ignored, but to the large flow pump!

- 2. displacement and flowDisplacement refers to the pump (or motor) every turn a week, by the size of the sealing chamber geometry variable discharge (or enter) the volume of liquid, commonly used unit is ml/r (ml / rev). Displacement can be changed as a variable pump (or variable motor), and the displacement can not be changed into a quantitative pump (or a quantitative motor).Actual flow is the amount of flow at the outlet (or inlet) when the pump (or motor) is operating. As the pump itself leaks, the actual flow is less than the theoretical flow. As the motor itself has an internal leakage, to achieve the specified speed, in order to compensate the leakage, the actual flow of input must be greater than the theoretical flow.

- Q:What's the difference between a concrete pump and a concrete pump truck?

- Concrete pump is a pumping machine used in the field, while the concrete pump truck is a truck mounted pump.

- Q:Common failure treatment of piston pump

- Table 15 common troubles and treatment of hydraulic pumpsFault phenomenon, x09 cause analysis, x09 elimination method(1) the pump does not carry oil; the x091. pump does not turn x09 (1); the motor shaft does not rotate1) missed connection power supply2) electrical wiring and component failure, x09 check electrical and troubleshootx09x09 (2) motor heating trip

- Q:What does "dual purpose" of water pump mean? Please expert advice

- 2, the pump must pay attention to maintenance after use, for example, when the pump is used up, the water pump should be put clean, it is best to remove the water pipe, and then rinse with water.5, the water pump on the tape should be removed, and then rinse with water after drying in the light place, do not put the tape in the dark damp place. Water pump tape must not be stained with oil, not to tape coated with some sticky things.6, to carefully check whether there are cracks in the impeller, the impeller fixed to the bearing on whether there is loose, cracks and loose if the phenomenon to be timely maintenance, if the water pump impeller should also be above the earth clean.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

General Purpose Pumping LYB vertical arc gear pump oil pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords