GB Standard Steel H Beam 394-414mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 394-414mm with High Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 394*398*11.0 | 147 | 400*408*21.0 | 197 |

| 400*400*13.0 | 172 | 414*405*18.0 | 232 |

Usage & Applications of GB Standard Steel H Beam 394-414mm with High Quality For Sale:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of GB Standard Steel H Beam 394-414mm with High Quality for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truc4. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

4. Delivered by container or bulk vessel

Production flow of GB Standard Steel H Beam 394-414mm with High Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

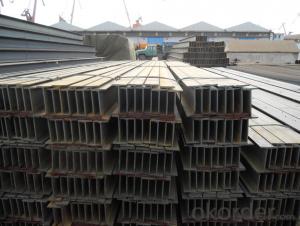

Images of GB Standard Steel H Beam 394-414mm with High Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q:How do steel H-beams compare to other structural beams, such as I-beams or W-beams?

- Wide flange beams, also referred to as Steel H-beams, offer numerous benefits when compared to other structural beams like I-beams or W-beams. One primary advantage lies in their impressive strength-to-weight ratio. H-beams are constructed to handle heavy loads while remaining relatively lightweight, making them ideal for a wide array of applications. In contrast to I-beams, H-beams possess wider flanges and thinner webs, resulting in a more even distribution of the load. This particular design characteristic enables H-beams to support heavier loads and provide enhanced stability. Furthermore, the wider flanges provide increased resistance against bending and twisting forces, rendering H-beams more rigid and less susceptible to deformations. Another advantage of H-beams over W-beams is their versatility and adaptability. H-beams can be easily modified, cut, and welded to suit specific project requirements. This flexibility allows for greater customization and cost-effectiveness, as it reduces the need for additional fabrication or complex connections. Additionally, H-beams offer superior lateral stability when compared to W-beams. The wider flanges of H-beams facilitate the efficient distribution of lateral loads, such as wind or seismic forces, thereby minimizing the risk of structural failure. Consequently, H-beams are often the preferred choice in regions prone to high winds or seismic activity. Nevertheless, it is important to acknowledge that the selection between steel H-beams, I-beams, or W-beams depends on the specific application and project requirements. Each beam type possesses its own unique advantages and limitations, underscoring the significance of consulting with a structural engineer or expert to determine the most suitable beam for a particular project.

- Q:Can steel H-beams be used in educational institutions and schools?

- Yes, steel H-beams can be used in educational institutions and schools. Steel H-beams are commonly used in construction for their strength, durability, and load-bearing capabilities. They are often used in the construction of bridges, high-rise buildings, and other large structures. In educational institutions and schools, steel H-beams can be used for various purposes such as supporting the framework of buildings, constructing gymnasiums and auditoriums, creating outdoor structures like canopies or walkways, and even for educational purposes in engineering or construction-related courses. The use of steel H-beams in educational institutions ensures the safety and stability of the structures, providing a conducive environment for learning and activities.

- Q:What are the structural integrity considerations for steel H-beams?

- When considering the structural integrity of steel H-beams, several key factors need to be taken into account. These considerations ensure that the H-beams can effectively withstand various loads and maintain their stability over time. 1. Load capacity: One of the primary concerns is the load capacity of the H-beams. The structural engineer must calculate and determine the maximum load that the beams can bear without experiencing deformation or failure. This involves analyzing the steel's yield strength, ultimate tensile strength, and the specific design of the H-beam. 2. Buckling resistance: H-beams are susceptible to buckling, which is the sudden lateral deflection or bending under compressive forces. To prevent buckling, the beams are designed with appropriate flange thickness, web depth, and spacing between the flanges. These factors contribute to the overall stiffness and rigidity of the H-beam. 3. Connection strength: The connections between H-beams and other structural components, such as columns or other beams, are crucial for maintaining the overall structural integrity. These connections must be designed to efficiently transfer loads and ensure that the H-beams do not detach or separate under various forces like tension, compression, or shear. 4. Fatigue resistance: H-beams are often subjected to cyclic loading, which can cause fatigue failure over time. To enhance their resistance to fatigue, the beams are typically designed with smooth transitions and rounded edges to reduce stress concentrations. Additionally, proper welding techniques and high-quality materials are used to minimize the risk of fatigue cracks. 5. Fire resistance: Steel H-beams can lose their strength rapidly under high temperatures. Therefore, fire protection measures, such as fireproof coatings or encasements, are often necessary to maintain the beams' structural integrity during a fire. These measures delay the temperature rise of the steel and prevent the beams from buckling or collapsing prematurely. Overall, the structural integrity considerations for steel H-beams involve analyzing their load capacity, buckling resistance, connection strength, fatigue resistance, and fire resistance. By addressing these factors, engineers can design H-beams that provide durable and reliable support in various construction applications.

- Q:What are the fire resistance ratings for steel H-beams?

- The fire resistance ratings for steel H-beams depend on various factors such as the dimensions of the beam, the type of fire protection applied, and the specific building codes and regulations in place. Generally, steel H-beams have inherent fire-resistant properties due to their high melting point and structural stability. However, to enhance their fire resistance, additional fireproofing materials such as intumescent coatings or fire-resistant insulations can be applied. These measures can significantly increase the fire resistance ratings of steel H-beams, allowing them to withstand fire exposure for extended periods, typically ranging from 30 minutes to several hours.

- Q:What is the height of the four fillet welds in H steel submerged arc welding, such as H600*300*6*12?

- The plate thickness is 6 and 12 respectively, and the fillet weld value is the same as the thickness of the thin plate (when the design does not require)

- Q:How do you calculate the maximum shear stress in steel H-beams?

- In order to determine the maximum shear stress in steel H-beams, one must consider the shear force acting on the beam and the cross-sectional properties of the beam. The shear stress in a beam can be calculated using the following formula: Shear Stress = (Shear Force * Distance from Neutral Axis) / (Area of Cross Section) Initially, the shear force acting on the beam needs to be calculated. This can be achieved by analyzing the external loads and support conditions. For instance, if the H-beam is subjected to a uniform distributed load, the shear force can be determined by multiplying the magnitude of the load by the length of the beam. Subsequently, the distance from the neutral axis to the point of interest must be determined. The neutral axis is the axis passing through the centroid of the cross-section, perpendicular to the applied shear force. The distance can be measured from the centroid to either the top or bottom edge of the beam, depending on the desired location for calculating the shear stress. Finally, the area of the cross-section of the H-beam needs to be determined. This can be accomplished by dividing the cross-section into various shapes (such as rectangles or triangles) and calculating the area of each shape individually. Once the areas of all the individual shapes are obtained, they can be summed to obtain the total cross-sectional area. Once the shear force, distance from the neutral axis, and area of the cross-section are known, they can be substituted into the formula to calculate the maximum shear stress. It should be noted that the maximum shear stress occurs at the point furthest from the neutral axis, typically at the top or bottom flange of the H-beam. When calculating the maximum shear stress in steel H-beams, it is important to consider additional factors such as bending moments, torsion, and any other relevant load combinations that may impact the structural integrity of the beam.

- Q:What are the different grades of steel used for manufacturing H-beams?

- The different grades of steel commonly used for manufacturing H-beams include A36, A572, A992, and A588.

- Q:What are the dimensions of a standard steel H-beam?

- The dimensions of a standard steel H-beam may differ based on the individual design and manufacturer. Nevertheless, there are frequently employed dimensions for these beams. Typically, they possess a flange width ranging from 100mm to 900mm, a web height ranging from 100mm to 300mm, and a weight per meter ranging from 17kg to 166kg. It should be emphasized that these dimensions may vary and be subject to specific requirements depending on the intended purpose and load-bearing capacity of the H-beam.

- Q:How do steel H-beams contribute to sustainable design?

- Steel H-beams contribute to sustainable design by providing structural strength and durability, allowing for the construction of long-lasting and resilient buildings. Their high load-bearing capacity enables the use of fewer materials, reducing resource consumption and minimizing waste. Moreover, steel H-beams are often made from recycled materials, reducing the demand for new raw materials and lowering carbon emissions. Additionally, their versatility and ease of installation make them suitable for various building types and designs, promoting flexibility and adaptability in sustainable construction practices.

- Q:How do you protect steel H-beams from corrosion?

- One effective way to protect steel H-beams from corrosion is by applying a protective coating, such as paint or a corrosion-resistant coating. This barrier layer creates a physical barrier between the steel and the external environment, preventing moisture and other corrosive elements from reaching the metal surface. Additionally, regular inspection and maintenance are crucial to identify and address any signs of corrosion early on, ensuring timely repairs or reapplication of protective coatings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GB Standard Steel H Beam 394-414mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords