GB Standard Steel H Beam 200*200*8.0mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 200*200*8.0mm with Good Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 200*200*8.0 | 49.9 | 250*125*6.0 | 29.0 |

| 248*124*5.0 | 25.1 | 244*175*7.0 | 43.6 |

Usage & Applications of GB Standard Steel H Beam 200*200*8.0mm with Good Quality For Sale:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Production flow of GB Standard Steel H Beam 200*200*8.0mm with Good Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

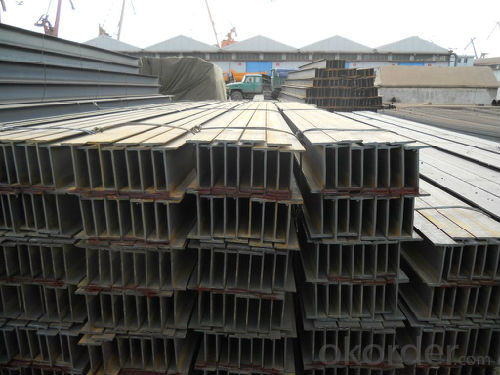

Images of GB Standard Steel H Beam 200*200*8.0mm with Good Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q:The difference and use of H type steel steel and steel.

- H steel is a new type of economical construction steel. H type steel cross section shape is reasonable in economy, good mechanical properties, rolling each point on the extended section is uniform, small internal stress, compared with the ordinary beam, a section modulus, light weight, saving advantages of metal, can make the building structure to reduce 30-40%; and because of its inner and outer legs parallel leg end is right, assembled into components, welding, riveting work can save up to 25%. Often used in large capacity requirements, large cross section stability, such as buildings, high-rise buildings, as well as bridges, ships, lifting transport machinery, equipment foundation, support, foundation piles.

- Q:Can steel H-beams be used in the construction of educational institutions or schools?

- Yes, steel H-beams can be used in the construction of educational institutions or schools. Steel H-beams are commonly used in construction due to their strength and durability. They provide excellent structural support, making them suitable for a wide range of applications, including educational buildings. Steel H-beams can be used in the construction of school buildings, gymnasiums, auditoriums, and other facilities within educational institutions. They are capable of supporting heavy loads, such as floors, walls, and roofs, ensuring the safety and stability of the structure. Additionally, steel H-beams are fire-resistant, termite-resistant, and have a long lifespan, making them a reliable choice for educational construction projects.

- Q:What are the different types of steel H-beams available in the market?

- There are several different types of steel H-beams available in the market, including standard H-beams, wide flange beams, and I-beams. Each type has its own unique shape and dimensions, designed for specific applications and load-bearing capacities.

- Q:Can steel H-beams be used in school or educational facility construction?

- Yes, steel H-beams can be used in school or educational facility construction. Steel H-beams are commonly used in construction due to their structural strength, durability, and ability to withstand heavy loads. They provide stability and support to the building's framework, making them suitable for constructing large educational facilities. Additionally, steel H-beams offer flexibility in design and can be easily integrated into various architectural styles, allowing for creative and modern educational spaces.

- Q:What are the welding requirements for steel H-beams?

- The welding requirements for steel H-beams typically involve using a specific welding process, such as shielded metal arc welding (SMAW) or gas metal arc welding (GMAW), to ensure proper fusion and strength. The welds should be performed by certified welders and meet specific codes and standards, such as those set by the American Welding Society (AWS). Additionally, proper pre-weld and post-weld treatments, such as cleaning, preheating, and stress relieving, may be necessary to achieve high-quality welds and prevent issues like distortion or cracking.

- Q:What are the different types of steel H-beam connections used in industrial facilities?

- Industrial facilities commonly use several different types of steel H-beam connections to provide structural stability and support in large-scale construction projects. The following are some frequently used types: 1. The most commonly used type is welded connections. These involve welding the H-beams together at the joint, creating a strong and rigid connection. Welded connections are known for their high strength and durability, making them suitable for heavy-duty applications. 2. Bolted connections involve securing the H-beams together using bolts and nuts. They can be easily disassembled and reassembled, making them ideal for situations where flexibility and future modifications are required. However, they may not be as strong as welded connections. 3. Riveted connections are an older method that uses metal rivets to join the beams together. They have been largely replaced by welded and bolted connections due to their higher cost and time-consuming installation process. However, they are still used in some historical or heritage structures. 4. Moment connections, also known as rigid connections, are designed to resist bending moments and provide greater stability. Additional plates are welded or bolted to the beam ends, creating a stiffer connection that can resist rotational forces. 5. Pinned connections allow for rotation between the beams, providing flexibility in the structure. They are commonly used in structures where movement or deflection is expected, such as bridges or earthquake-resistant buildings. Pinned connections can be achieved through the use of specialized pins or bearings. 6. Shear connections transfer shear forces between the beams. They are typically made through the use of bolts or welding additional plates to the beam ends. Shear connections are crucial for ensuring the structural integrity of the H-beam system during lateral loads or vibrations. It is important to consider factors such as load-bearing requirements, structural design, project specifications, and cost when selecting the appropriate H-beam connection type. Consulting with a structural engineer or construction professional is recommended to determine the most suitable connection type for a specific industrial facility.

- Q:What are the design considerations for steel H-beams in cold climates?

- To guarantee the structural integrity and effectiveness of steel H-beams in cold climates, there are several vital factors that need to be considered during the design process. These considerations are as follows: 1. Material Selection: It is crucial to select the appropriate grade of steel for cold climates. Steel grades with higher yield strength and toughness, such as ASTM A572 or A588, are recommended due to their ability to withstand low temperatures and resist brittle fracture. 2. Impact of Cold Temperatures: Cold temperatures can make steel more brittle, increasing the risk of fracture. Designers should take into account the effects of low temperatures on the steel's ductility and toughness, and consider potential temperature variations throughout the year. 3. Structural Stability: Cold climates often experience severe weather conditions, including heavy snow loads and strong winds. Designers must ensure that the H-beams have sufficient load-bearing capacity and stability against lateral forces. It is necessary to consider not only the weight of the snow but also the potential impact of snow drifts on the beams. 4. Thermal Expansion and Contraction: Steel expands and contracts with temperature fluctuations. In cold climates, where temperatures can vary significantly between seasons, it is vital to incorporate proper expansion joints and allow for thermal movement. This prevents excessive stress and potential damage to the H-beams. 5. Corrosion Protection: Cold climates often have high levels of moisture, which can accelerate the corrosion process. Designers should consider using protective coatings, such as galvanizing or epoxy, to prevent rust and prolong the lifespan of the H-beams in these environments. 6. Insulation: In extremely cold climates, insulation can be utilized to minimize heat transfer and reduce the risk of thermal bridging. This, in turn, helps prevent condensation and potential corrosion. Careful integration of insulation into the design is necessary to maintain the structural integrity of the H-beams. 7. Connection Design: Proper design of connections between H-beams is crucial to ensure their performance in cold climates. Connections should be designed to accommodate potential movement due to thermal expansion and contraction, while maintaining structural stability and load-bearing capacity. By considering these design factors, engineers can ensure that steel H-beams perform optimally and have a long lifespan in cold climate environments.

- Q:Are Steel H-Beams resistant to mold or mildew?

- Yes, steel H-beams are resistant to mold or mildew growth due to their non-porous and non-organic nature.

- Q:What are the common methods for joining steel H-beams in construction?

- There are several common methods for joining steel H-beams in construction. 1. Welding: This is the most common method used to join steel H-beams. The beams are aligned and welded together using either arc welding or gas welding techniques. Welding provides a strong and durable connection between the beams, ensuring structural integrity. 2. Bolted Connections: Another method is to use bolts to connect the steel H-beams. Holes are drilled into the flanges of the beams, and bolts are inserted through these holes and tightened using nuts. This method allows for easy disassembly and reassembly if needed. 3. Riveting: Riveting involves using rivets to join the steel H-beams. Holes are drilled into the flanges and web of the beams, and rivets are inserted through these holes and then hammered or pressed to secure them. Riveting was a commonly used method in the past, but it has been largely replaced by welding and bolted connections due to its time-consuming nature. 4. Adhesive Bonding: In some cases, adhesive bonding can be used to join steel H-beams. High-strength adhesives are applied to the surfaces of the beams, and they are then pressed together. This method is not as commonly used as welding or bolted connections, but it can be a viable option in certain situations. Overall, welding and bolted connections are the most commonly used methods for joining steel H-beams in construction. These methods provide strong and reliable connections, ensuring the stability and integrity of the structure.

- Q:How do steel H-beams perform in snow-prone areas?

- Steel H-beams perform well in snow-prone areas due to their structural integrity and strength. The H-shape of these beams provides resistance against bending and twisting forces, making them suitable for withstanding heavy snow loads. The design of H-beams allows for efficient distribution of weight, which reduces the risk of structural failure under the weight of accumulated snow. Additionally, steel is a durable material that is not affected by extreme cold temperatures or moisture, making it highly resistant to corrosion and deterioration caused by snow and ice. This durability ensures that the H-beams maintain their structural integrity over time, even in harsh winter conditions. Furthermore, steel H-beams offer versatility in construction, allowing for various designs and configurations that can accommodate the unique requirements of snow-prone areas. These beams can be fabricated to specific lengths and sizes, ensuring the optimal distribution of loads and providing the necessary support to withstand heavy snowfall. In conclusion, steel H-beams are an excellent choice for construction in snow-prone areas. Their strength, durability, and versatility make them highly capable of withstanding heavy snow loads and maintaining structural integrity in challenging winter conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GB Standard Steel H Beam 200*200*8.0mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords