GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar Details

| Grade: | Q235,Q345/SS400,SS540 | Standard: | ASTM,GB,JIS | Thickness: | 2.5mm-20mm |

| Width: | 12mm-150mm | Length: | customized flat steel | Place of Origin: | China (Mainland) |

| Technique: | Hot Rolled | Model Number: | customized flat steel | Application: | structure construction/making fence |

Packaging & Delivery

| Packaging Detail: | Mills standard export strong Packing |

| Delivery Detail: | 25-45 days |

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar Specifications

Full size

Grade:Q195, Q215, Q235

Low price

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar Description

Grade:Q235-Q345/SS400-SS540/S235JR-355JR

Standard: GB/JIS/EN/ASTM

Steel flat bar thick : 2.5-20mm

Steel flat bar wide : 12-150mm

Steel flat bar length :Any you want

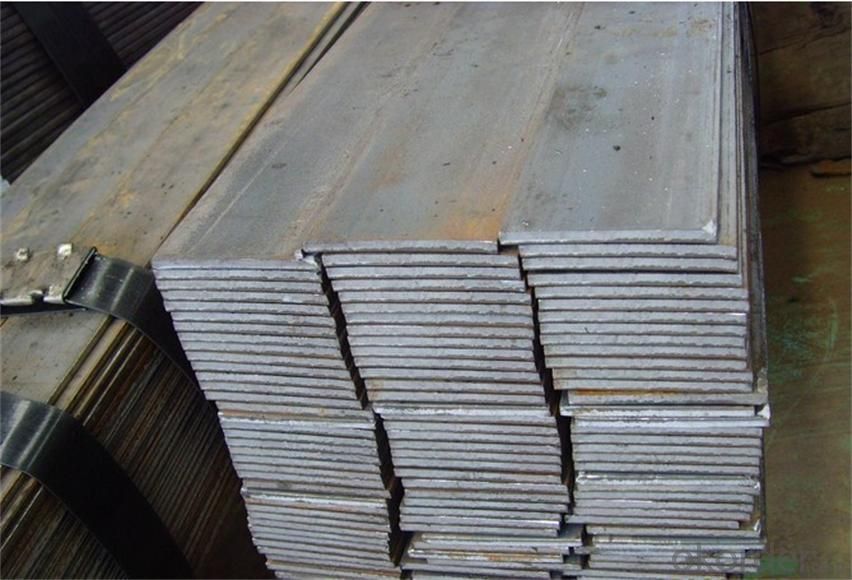

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar Pictures

- Q:Can steel sheets be used for manufacturing storage cabinets?

- Yes, steel sheets can be used for manufacturing storage cabinets. Steel is a durable and strong material that is commonly used in the construction of cabinets due to its ability to withstand heavy loads and provide long-lasting storage solutions. Additionally, steel sheets can be easily fabricated into various shapes and sizes, making them suitable for manufacturing cabinets of different dimensions.

- Q:What are the different manufacturing processes for steel sheets?

- There are several manufacturing processes for steel sheets, including hot rolling, cold rolling, and electro-galvanizing. Hot rolling involves heating the steel above its recrystallization temperature and then passing it through rollers to achieve the desired thickness and shape. Cold rolling, on the other hand, involves passing the steel through rollers at room temperature to further refine its thickness and surface finish. Electro-galvanizing is a process where a layer of zinc is electroplated onto the steel sheet to provide corrosion resistance. Other processes such as pickling, annealing, and coating may also be involved in the manufacturing of steel sheets.

- Q:Are steel sheets suitable for furniture manufacturing?

- Yes, steel sheets are suitable for furniture manufacturing. They are strong, durable, and versatile, allowing for the creation of various furniture designs. Steel sheets can be easily shaped, cut, and welded to create different furniture components, such as frames, legs, and supports. Additionally, steel sheets can be finished with different coatings or paints to enhance their appearance and protect against corrosion. Overall, steel sheets are a popular choice for furniture manufacturing due to their strength, durability, and design flexibility.

- Q:Can steel sheets be used for bulletproof applications?

- Yes, steel sheets can be used for bulletproof applications. Steel is a strong and durable material that can provide effective protection against bullets. However, the thickness and type of steel used, along with the design and construction of the application, are crucial factors in determining its effectiveness as a bulletproof solution.

- Q:Can steel sheets be bent or folded?

- Yes, steel sheets can be bent or folded. Steel is a highly versatile material that can be manipulated into various shapes and forms. In fact, the ability to bend or fold steel sheets is one of the reasons why it is widely used in construction, manufacturing, and other industries. Bending or folding steel sheets can be achieved through different methods such as press braking, roll bending, or using specialized tools like bending machines. The process involves applying force or pressure to the steel sheet, causing it to deform and take on the desired shape.

- Q:What are the properties of steel sheets?

- Steel sheets have several advantageous properties, including high strength and durability, excellent corrosion resistance, good thermal conductivity, and the ability to be easily formed and welded.

- Q:How are steel sheets used in construction?

- Steel sheets are commonly used in construction for various purposes such as roofing, wall cladding, and structural support. They provide strength, durability, and resistance to harsh weather conditions. Steel sheets can be formed into different shapes and sizes, making them versatile for a wide range of construction applications.

- Q:Can steel sheets be used for decorative wall panels?

- Yes, steel sheets can be used for decorative wall panels. They can provide a modern and industrial aesthetic to a space and offer durability and versatility in design options.

- Q:What is the difference between a HRPO and HRSPO steel sheet?

- HRPO and HRSPO are two types of steel sheets that differ in the way they are manufactured and their resulting properties. HRPO, which stands for Hot Rolled Pickled and Oiled, involves subjecting a hot rolled steel coil to a pickling process. This process removes impurities and scale from the surface using an acid bath. After pickling, the steel sheet is oiled to prevent corrosion during storage and transportation, resulting in a smooth and clean surface finish. On the other hand, HRSPO, which stands for Hot Rolled Skin Passed and Oiled, goes through an additional process called skin pass after pickling and oiling. During this process, the steel sheet is passed through a set of rolls to improve the surface finish and reduce its thickness. The skin pass process also gives the steel a certain level of cold work, enhancing its mechanical properties. In terms of properties, HRPO steel sheets have good formability, weldability, and paintability due to their clean surface and lack of scale. They are commonly used in applications that require a smooth surface finish, such as appliances, automotive parts, and exposed architectural components. HRSPO steel sheets, on the other hand, have an even better surface finish and reduced thickness compared to HRPO sheets. This makes them ideal for demanding applications where precise dimensional control and surface aesthetics are crucial, such as automotive body panels, electrical enclosures, and furniture manufacturing. In summary, the main difference between HRPO and HRSPO steel sheets lies in the additional skin pass process that HRSPO undergoes. This process results in improved surface finish, reduced thickness, and enhanced mechanical properties. The choice between the two types of steel sheets depends on the specific requirements of the application, such as surface quality, dimensional control, and mechanical performance.

- Q:What is the difference between a brushed and polished steel sheet?

- A brushed steel sheet and a polished steel sheet differ in terms of their surface finishes. A brushed steel sheet is characterized by a pattern of parallel lines or scratches on its surface, created using abrasive materials or tools. The purpose of brushing is to give the steel sheet a textured appearance, which helps to hide fingerprints, scratches, and wear over time. It also provides a more industrial, matte finish. On the other hand, a polished steel sheet has a smooth and glossy surface. Polishing involves using polishing compounds or abrasive materials to remove imperfections, scratches, and oxidation from the steel surface. This process creates a reflective and mirror-like finish, enhancing the aesthetic appeal of the steel sheet. Polished steel sheets are commonly used in applications where appearance and visual appeal are important, such as architectural design, interior decoration, and high-end products. In summary, the main difference between a brushed and polished steel sheet lies in their surface finishes. Brushed steel sheets have a textured, matte appearance, while polished steel sheets have a smooth and glossy, mirror-like finish. The choice between the two depends on the desired aesthetic, functional requirements, and the intended application of the steel sheet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords